Temporary support device for frame-type steel-structure combined oblique stand column and construction method

A technology of temporary support and inclined columns, which is applied to the preparation of building components on site, pillars, building structures, etc. It can solve the problems of consumption of steel pipes and fasteners, troublesome and inconvenient assembly and disassembly of lantern-type steel trusses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

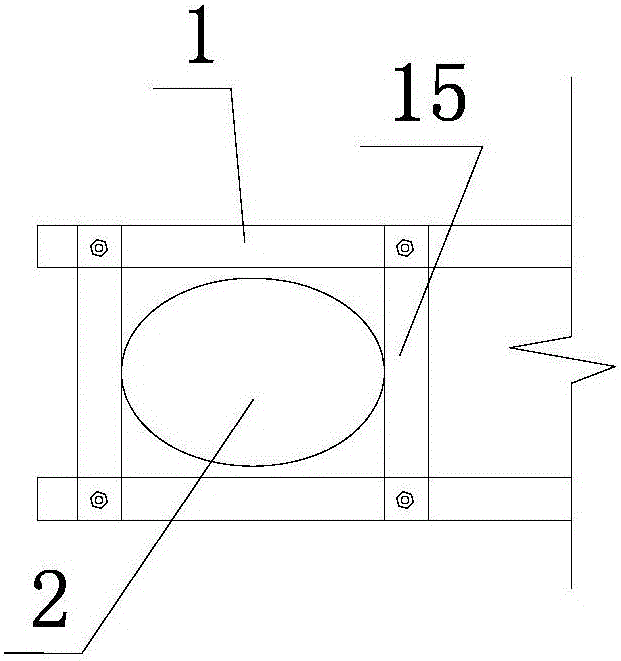

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the temporary support device of the combined inclined column of the frame type steel structure of the present invention comprises two parallel rails 1 placed on the ground, and one end of the two tracks 1 is connected with the inclined column monomer of the first floor. The bottom of 2 is fixed. Specifically, the temporary support mechanism also includes two connecting rods 15 perpendicular to the track 1, the two ends of the two connecting rods 15 are respectively fixed with the two tracks 1 to form a square-shaped frame, and the inclined columns on the first floor are single The bottom end of body 2 is tightened in the frame.

[0030] A trolley 3 is slidably fitted on the two rails 1; the top of each inclined column monomer 2 is hinged with an inclined support rod 4, sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com