Hot press and hot pressing method for production of bamboo wood composite container floor

A container floor, bamboo and wood composite technology, which is applied in the joining of wooden veneers, chemical instruments and methods, lamination and other directions, can solve the problems of low pressure sensitivity, easy rebound of composite panels, and difficult pressure adjustment, and reduce the rebound phenomenon, pressure uniformity, the effect of preventing uneven pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

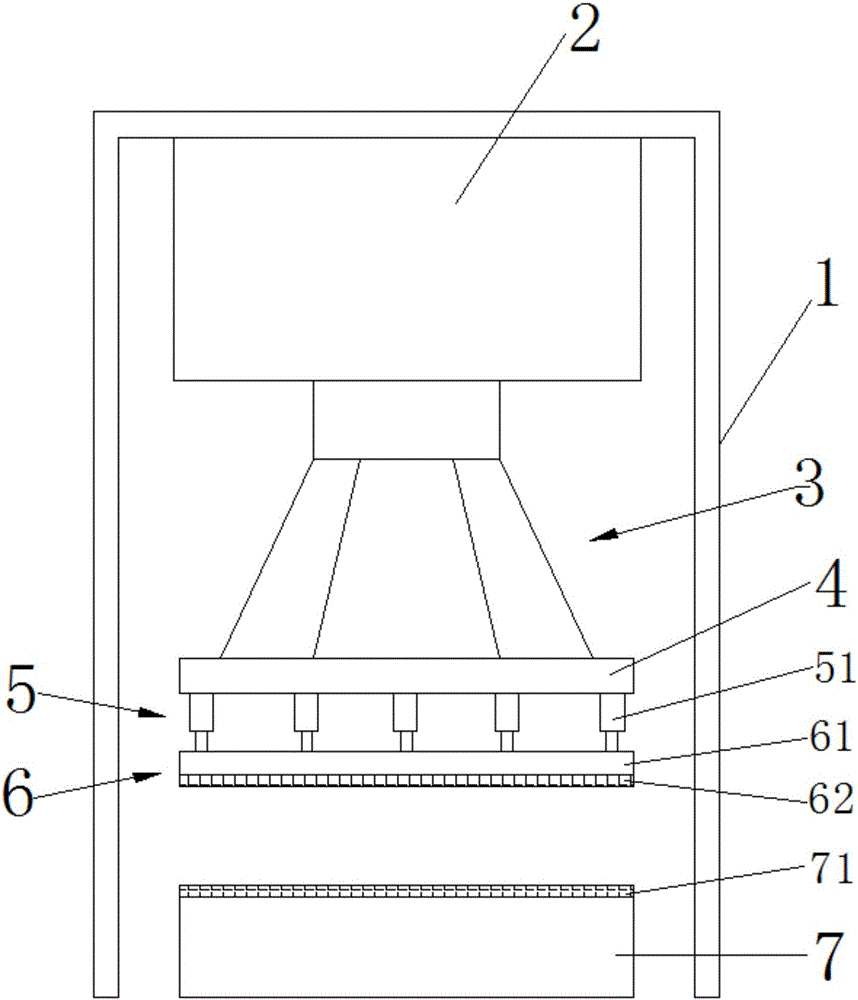

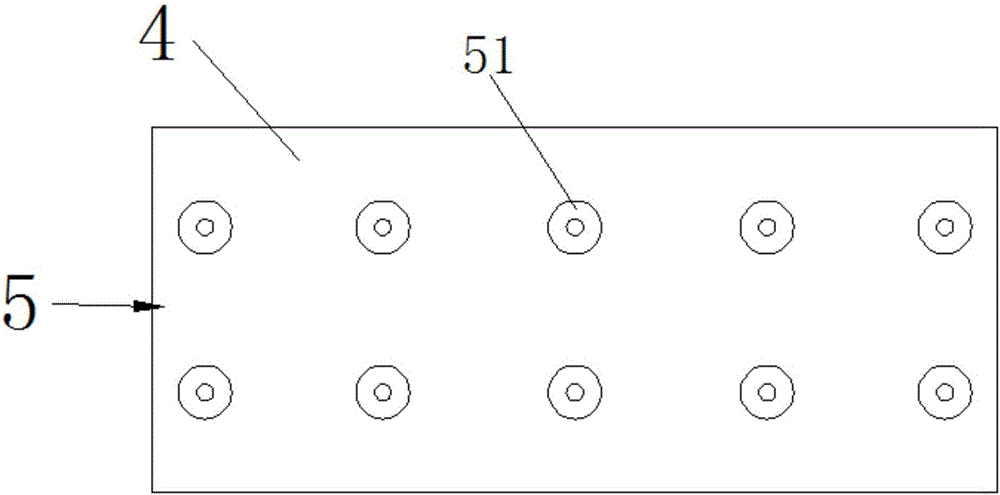

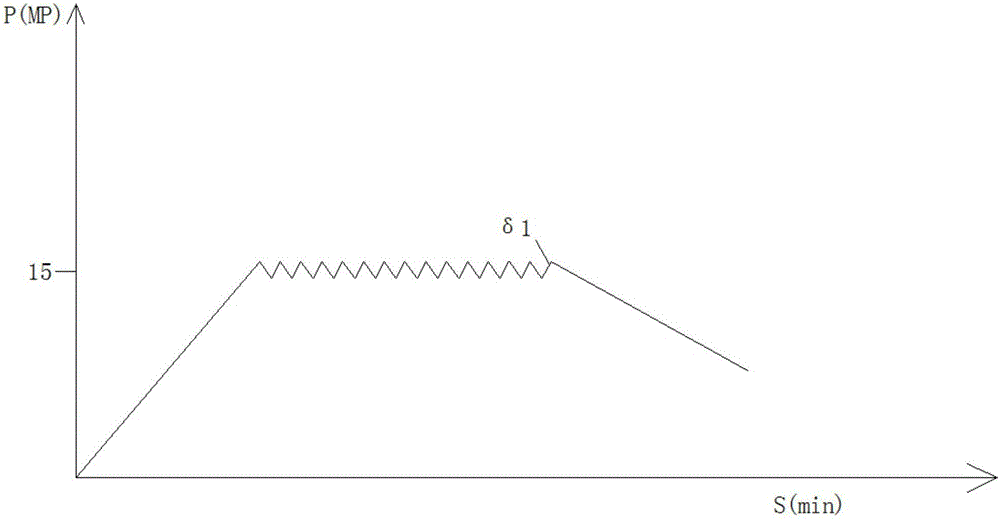

[0029] Such as figure 1 , 2 As shown, a hot press machine for the production of bamboo-wood composite container floor, including a frame 1 and a hydraulic device 2, a pressure bearing plate 4, a pneumatic device array group 5, The hot pressing plate 6 and the workbench 7; the air pressure device array group 5 is arranged on the lower surface of the pressure bearing plate 4; the hydraulic device 2 drives the pressure bearing plate 4 to move up and down; the air pressure device array group 5 drives the hot pressing plate 6 Moving up and down; the hot pressing plate 6 includes an upper structural layer 61 and a lower heating layer 62 of the hot pressing plate; the worktable 7 is arranged below the hot pressing plate 6; the upper end of the worktable 7 is provided with a worktable heating layer 71.

[0030] Wherein, the hot press for the produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com