Cassava puller clamping and pulling device

A cassava and clamping technology, which is applied to agricultural machinery and tools, hand tools, applications, etc., can solve the problems of large damage to cassava, difficulty in storage, and no reports on the growth of cassava, so as to reduce the damage rate and reduce the stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

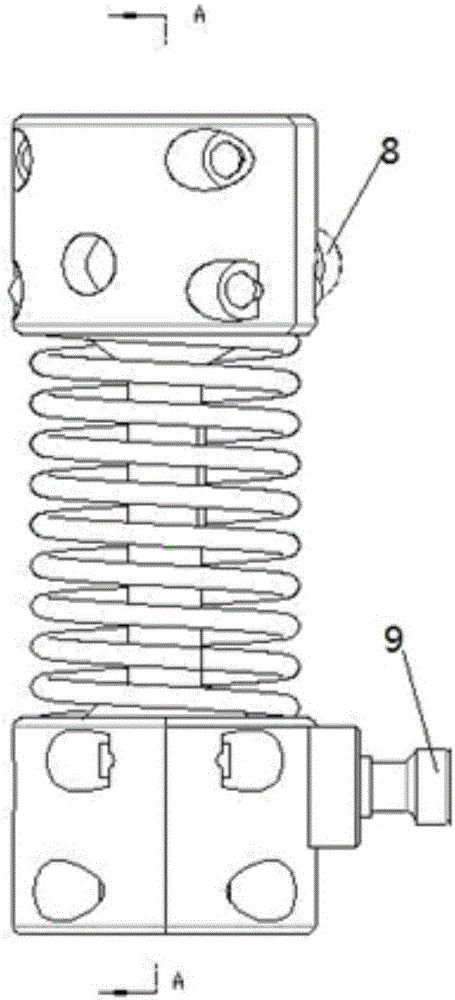

[0017] see Figure 1 to Figure 2 , the clamping and pulling device of the cassava pulling machine according to the present invention, the specific structure is: the upper sphere 2 is connected with the upper sphere seat 1 in a spherical hinge, the lower sphere 5 is connected with the lower sphere seat 6 in a spherical hinge, and the upper sphere 2 And the lower sphere 5 is threadedly connected with the screw rod 3, the upper clamping bolt 8 is threaded with the upper sphere seat 1, the lower clamping bolt 9 is threaded with the lower sphere seat 6; the upper sphere seat 1 is composed of left and right parts, the left , right two parts are threadedly connected by double-ended stud 7, and lower ball seat 6 is made of left and right two parts, and left and right two parts are connected by double-ended stud thread 7; Lower ball seat 6 is threadedly connected with cassava clip, spring 4 is fixed between the upper ball seat 1 and the lower ball seat 6.

[0018] The working principl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com