Barrel replacing method used in period that oak barrels stores Baijiu

A technology of oak barrels and liquor, applied in the preparation of alcoholic beverages, etc., to achieve the effect of long aftertaste and strong taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

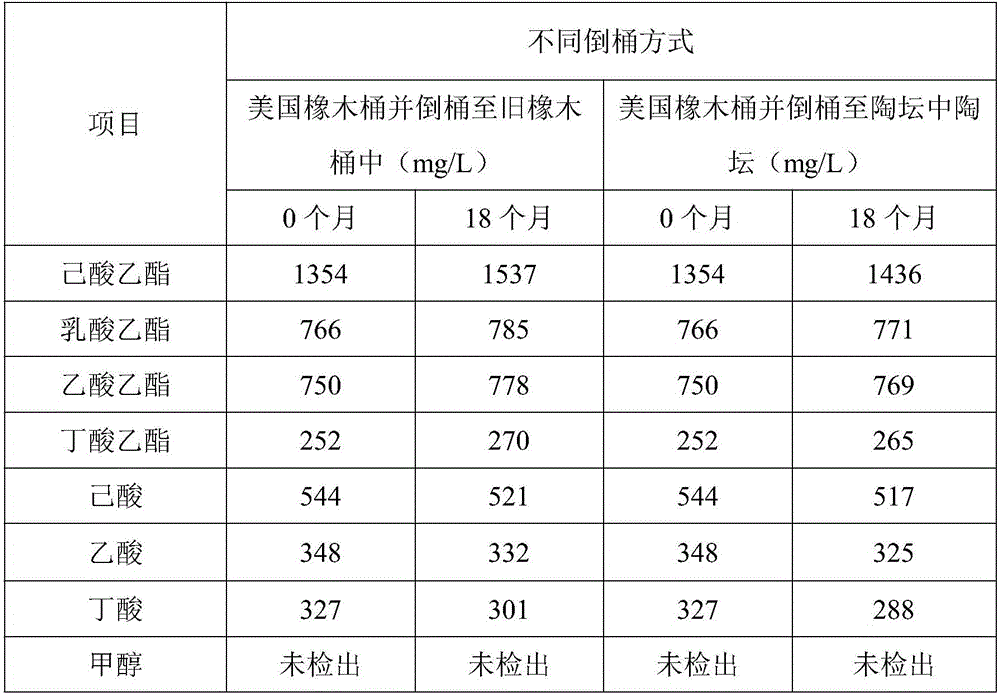

[0023] Store liquor in 225L new American oak barrels, cover the oak barrel lid (not completely sealed) for the first 2 days, then completely seal the barrel lid of the oak barrel, and place it in a cool and dry room with a temperature of 25°C and a humidity of 70%. , stored for a total of 6 months, then poured into old oak barrels and stored in the same environment for 1 year. Then take it out and enter the post-processing process, filling and packaging into finished wine. After being stored in old oak barrels for 1 year, sensory evaluation and determination of loss rate and aroma components were carried out, as shown in Table 1, Table 2, and Table 3.

Embodiment 2

[0025] Store liquor in 225L new American oak barrels, cover the oak barrel lid (not completely sealed) for the first 2 days, then completely seal the barrel lid of the oak barrel, and place it in a cool and dry room with a temperature of 25°C and a humidity of 70%. , stored for a total of 6 months, then poured into a pottery jar and stored in the same environment for 1 year. Then take it out and enter the post-processing process, filling and packaging into finished wine. After being stored in the pottery altar for 1 year, sensory evaluation and determination of loss rate and aroma components were carried out, as shown in Table 1, Table 2, and Table 3.

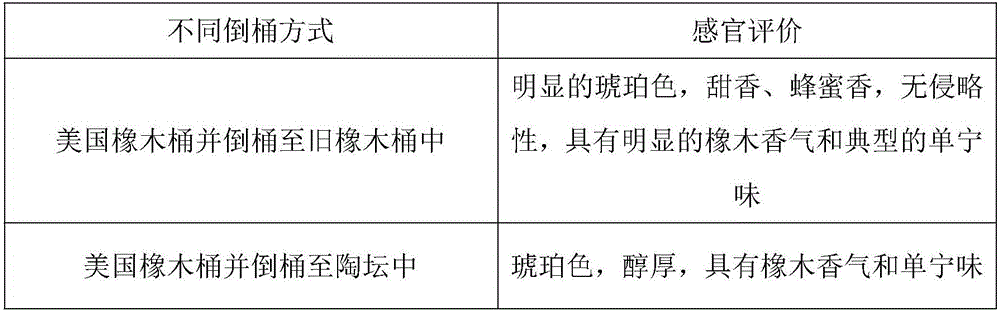

[0026] Table 1 Sensory evaluation results after storage in different barrel-inverted ways

[0027]

[0028] Table 2 Loss rate after storage in different ways of dumping buckets

[0029] Different Ways to Empty the Bucket

Attrition rate

American oak barrels and decanting into old oak barrels

0.8%

...

Embodiment 3

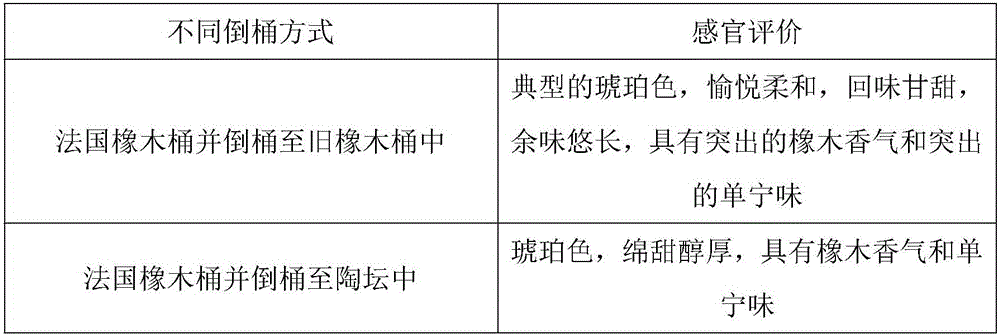

[0034] Store liquor in 350L new French oak barrels, cover the oak barrel lid (not completely sealed) for the first 2 days, then completely seal the barrel lid of the oak barrel, and place it in a cool and dry room with a temperature of 22°C and a humidity of 65%. , stored for a total of 6 months, then transferred to old oak barrels and stored in the same environment for 1 year. Then take it out and enter the post-processing process, filling and packaging into finished wine. After storing in old oak barrels for 1 year, sensory evaluation and determination of loss rate and aroma components were carried out, as shown in Table 4, Table 5 and Table 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com