Welding device

A technology of welding device and driving device, which is applied to welding equipment, welding accessories, electrode support devices, etc., can solve the problems of troublesome welding, affecting the welding effect, unable to lift the welding torch synchronously, etc., and achieve the effect of simple welding operation and good welding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

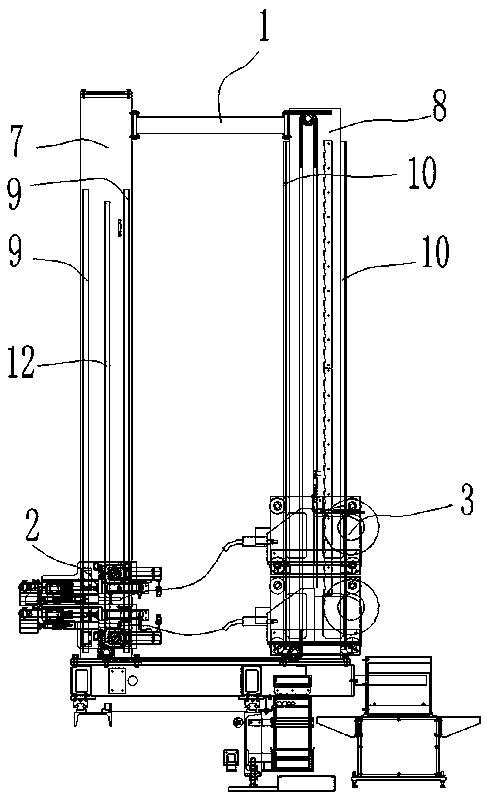

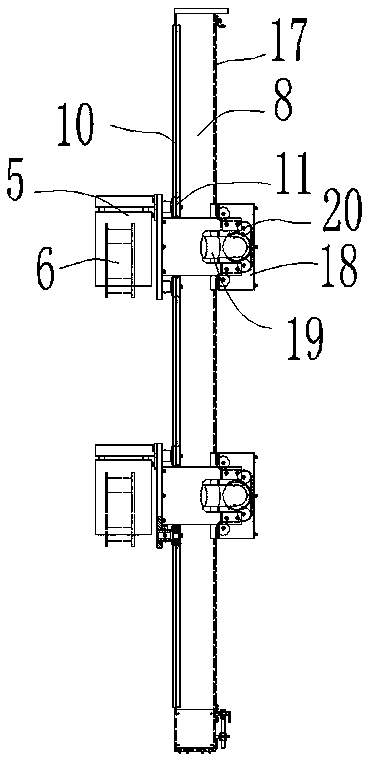

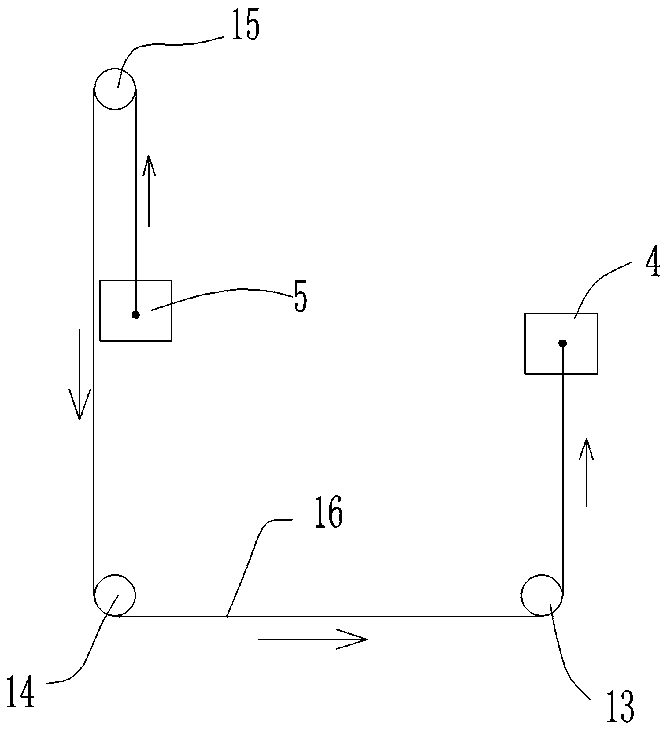

[0027] refer to figure 1 , figure 2 , image 3 , Figure 4 , a welding device, comprising a base, a gantry 1 slidably arranged on the base, a gantry driving device for driving the gantry to slide forward and backward is provided between the base and the gantry 1 , The gantry 1 is provided with a welding torch device 2 and a welding wire feeding device 3 . The gantry driving device is used to drive the gantry 1 to slide back and forth, so that the welding torch device 2 on the gantry 1 moves back and forth for welding. The gantry driving device can adopt multiple driving mechanisms in the prior art, for example, a gantry driving motor is set on the gantry frame, a gantry driving gear is set at the output end of the gantry driving motor, a gantry driving rack is set on the base, and the gantry driving gear and the gantry driving ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com