A sealing structure in which the load-bearing beam passes through the flue guard plate

A technology of sealing structure and load-bearing beam, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of metal fatigue, cracks, damage, etc., and achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

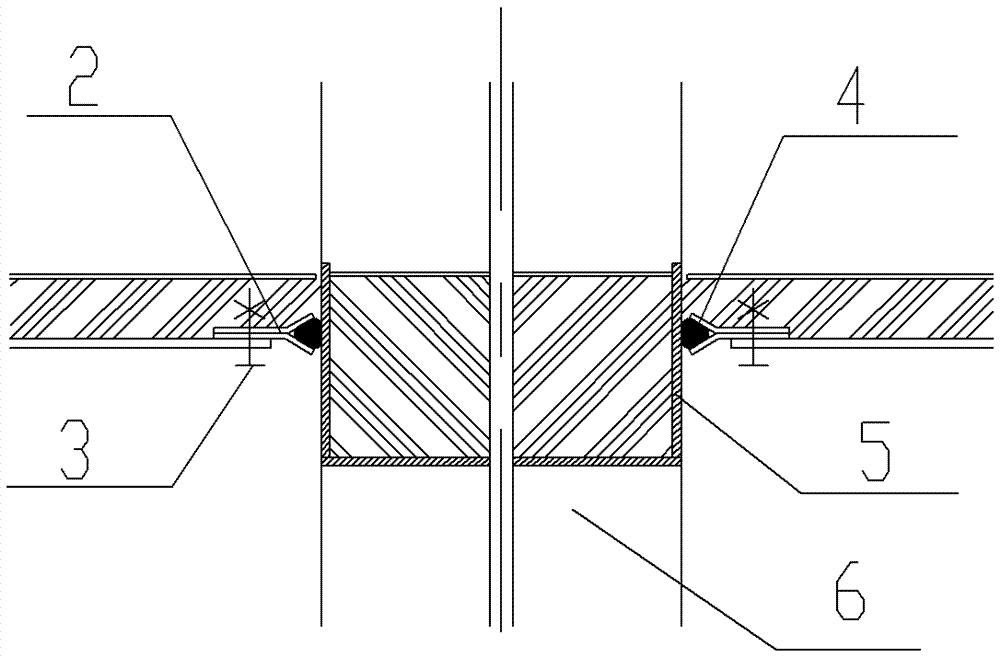

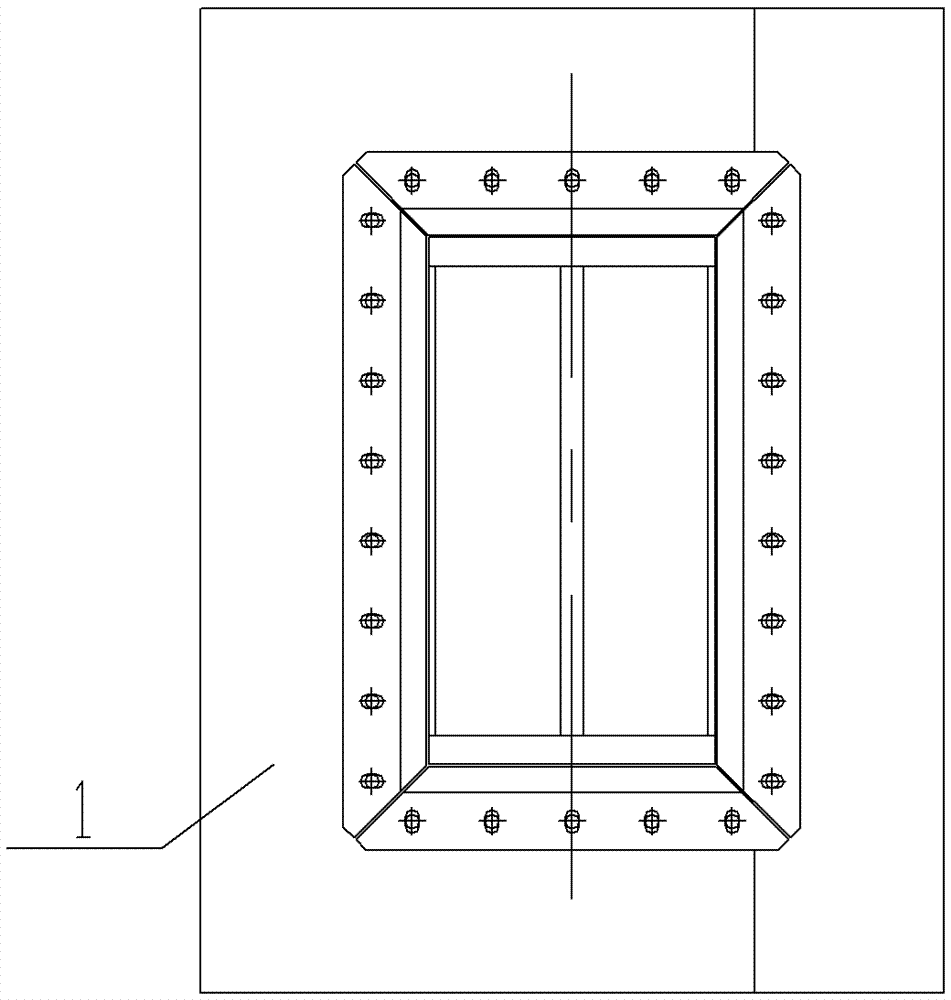

[0011] See figure 1 , figure 2 As shown, a sealing structure in which a load-bearing beam passes through a flue guard plate, which includes a load-bearing beam 6 and a flue guard plate 1, the load-bearing beam 6 passes through the flue guard plate 1, and the outer side of the load-bearing beam 6 and the flue guard plate 1 are connected. There is a gap between them. A sealing plate 5 is installed on the outer side of the load-bearing beam 6. Corresponding to the outer side of the sealing plate 5, a Y-shaped fork 2 is installed on the flue guard plate 1. The opening of the Y-shaped fork 2 faces the sealing plate 5. The Y-shaped fork Between the opening of 2 and the sealing plate 5, there is an insulation ring 4 which is close to the outer peripheral surface of the sealing plate 5. The insulation ring 4 is surrounded by insulation ropes, and has a simple structure, convenient installation and low cost. The four sealing plates 5 are then formed into a square structure, and four ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com