Integral cup feeding and collecting device of curved surface offset printing press

An offset printing machine, an integrated technology, applied in the direction of the conveyor control device, packaging material feeding device, printing machine, etc., can solve the problems of low labor efficiency, uncoordinated cup feeding operation station and cup collection operation station, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

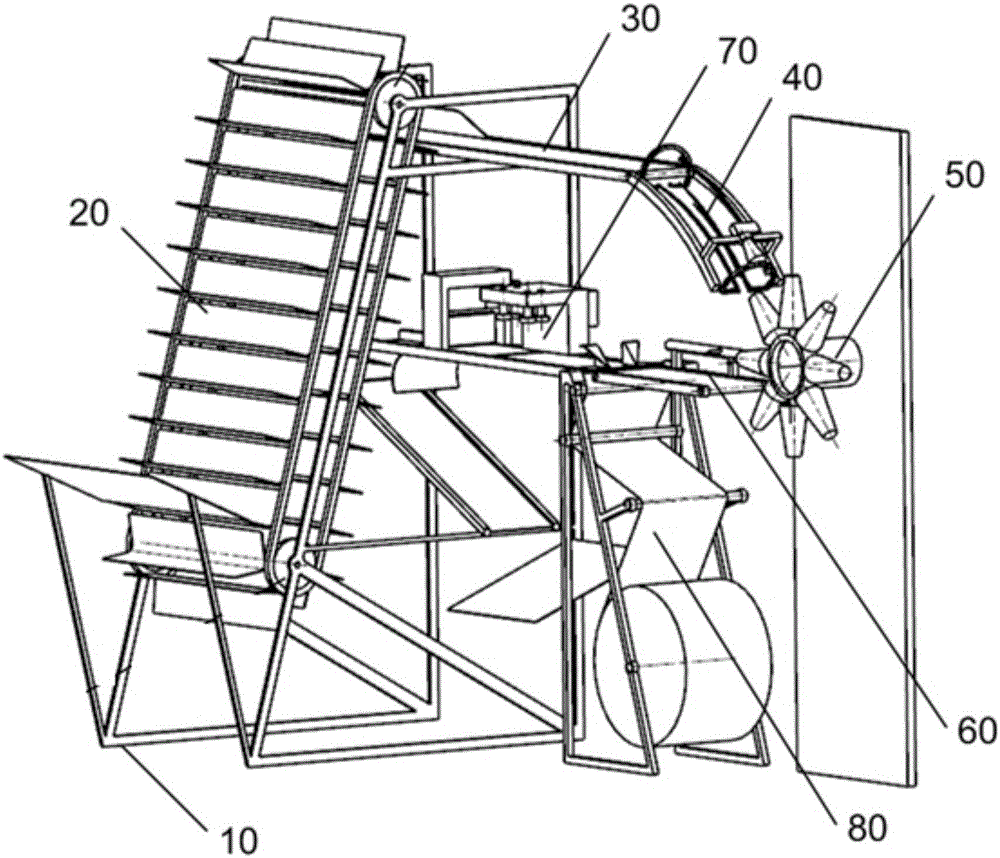

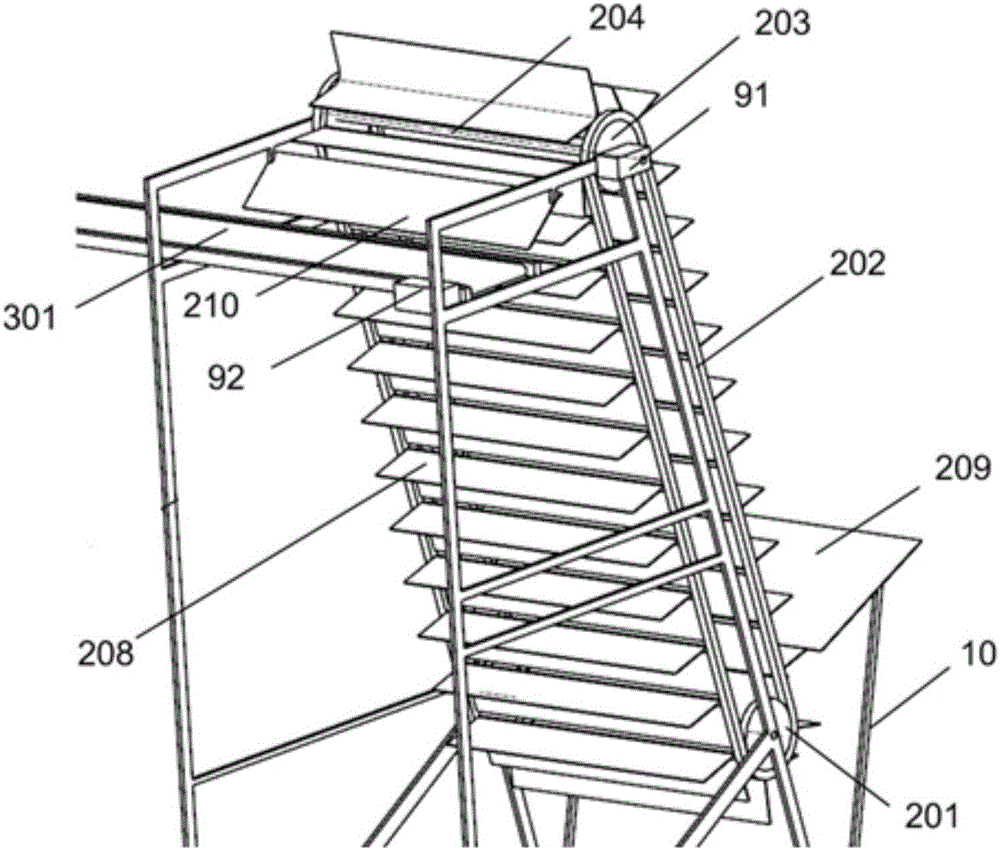

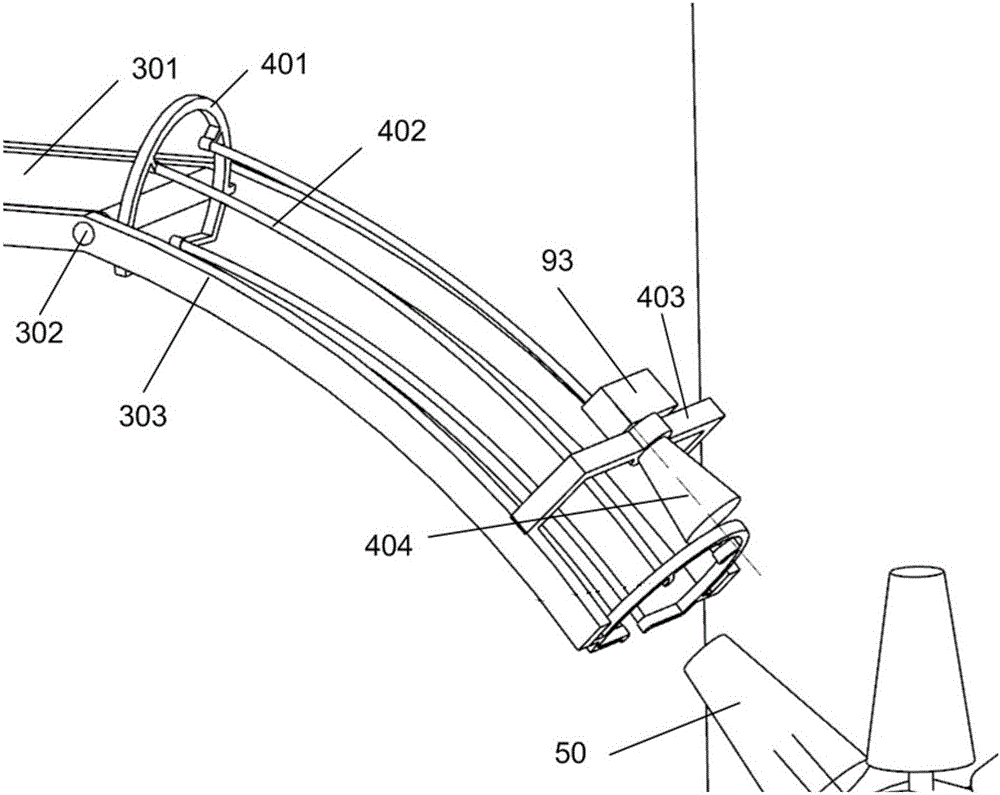

[0073] The embodiment of the present application provides an integrated cup feeding and collecting device for a curved offset printing machine, which solves or partially solves the problem that the cup feeding device and cup collecting device in the prior art adopt a split design, which causes the cup feeding operation station and cup collecting operation. The technical problems of uncoordinated workstations and low labor efficiency have realized the integrated design of cup feeding and cup collection. The cup feeding module, cup collection module and packing module are installed on a main frame to ensure The pick-up station is in the same area, and the cup feeding speed control and packaging speed control are connected to the PLC control system of the curved surface offset printing machine through the control interface of the servo motor, so as to realize the technical effect of automatic operation coordinated with the printing speed.

[0074] See attached figure 1 , the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com