Automatic weighing type main material discharging device

A main material and automatic technology, applied in the field of material conveying equipment, can solve the problems of large manual weighing errors, high labor costs, and dust hazards, and achieve the effect of improving measurement efficiency, efficiency, and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

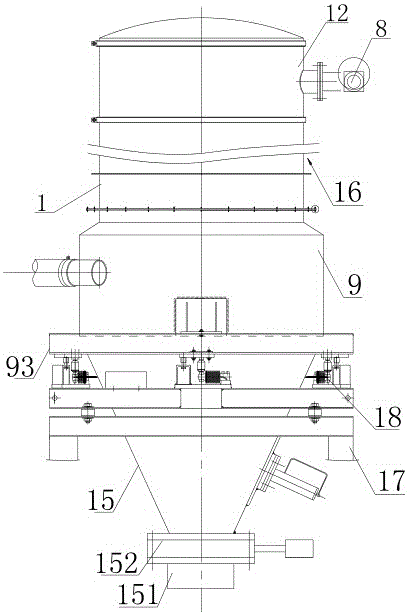

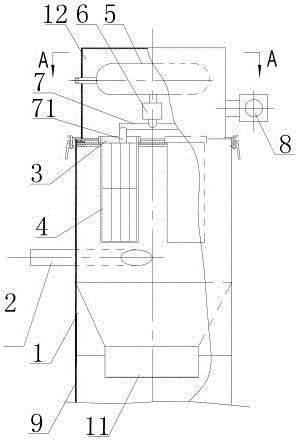

[0017] like figure 1 , figure 2 , image 3 As shown, the feeding device of the automatic weighing type main material includes: receiving bin 9, the bottom of receiving bin 9 is fixedly connected with receiving hopper 15, the bottom of receiving hopper 15 is provided with a feeding port 151, and the feeding port 151 is A feeding valve 152 capable of controlling the opening and closing of the feeding port 151 is provided, and the feeding valve 152 described in this embodiment is a butterfly valve. The top of receiving bin 9 is provided with vacuum feeder 16, and vacuum feeder 16 can transport the main material in the main material storage tank to receiving bin 9, and described receiving bin 9 is supported and installed on frame 17 Above, at least two load cells 18 are arranged between the receiving bin 9 and the frame 17 . Specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com