Construction method of subway station

A technology for subway stations and construction methods, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of complex structure, large waste and reconstruction work, long construction period, etc., and achieve simple and safer stress, labor saving, Anti-seismic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

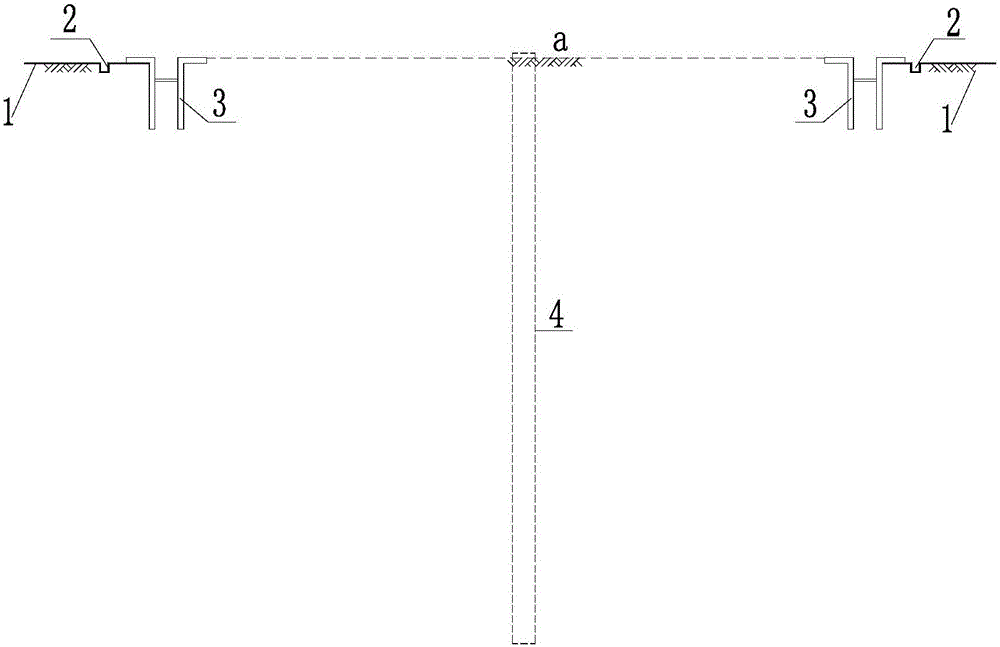

[0076] A kind of subway station construction method of the present invention, comprises the following steps: can refer to Figure 1 to Figure 9

[0077] Step S1:

[0078] S11. Complete pipeline and road construction according to the pipeline diagram and traffic relief diagram within the construction area of the station, and carry out construction enclosure; and level the ground of the site within the construction enclosure area according to the construction drawing of the main foundation pit enclosure of the station.

[0079] S12. Construction of the guide wall 3 for guiding the construction of the enclosure structure piles or the ground connection wall 7 is carried out on the site within the construction scope of the main body of the station.

[0080] S13. Carry out the construction of the drainage facility 2 during the construction of the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com