A construction method for grooved tracks reserved for general integral ballast beds in subway depots

A technology for subway depots and integral track beds, which is applied to tracks, track laying, track maintenance, etc., can solve the problems of difficult construction, large control deviation of track state geometric dimensions, uncontrollable track bottom slope, etc., and achieves simple and economical construction. The cost of engineering measures, the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

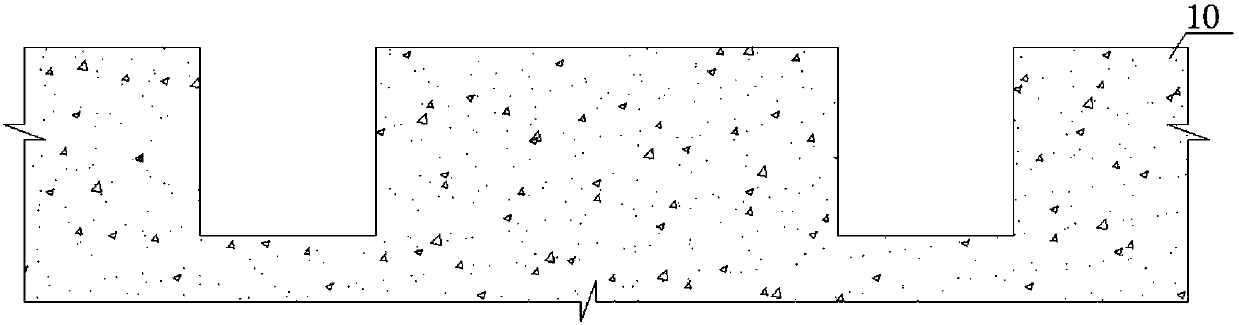

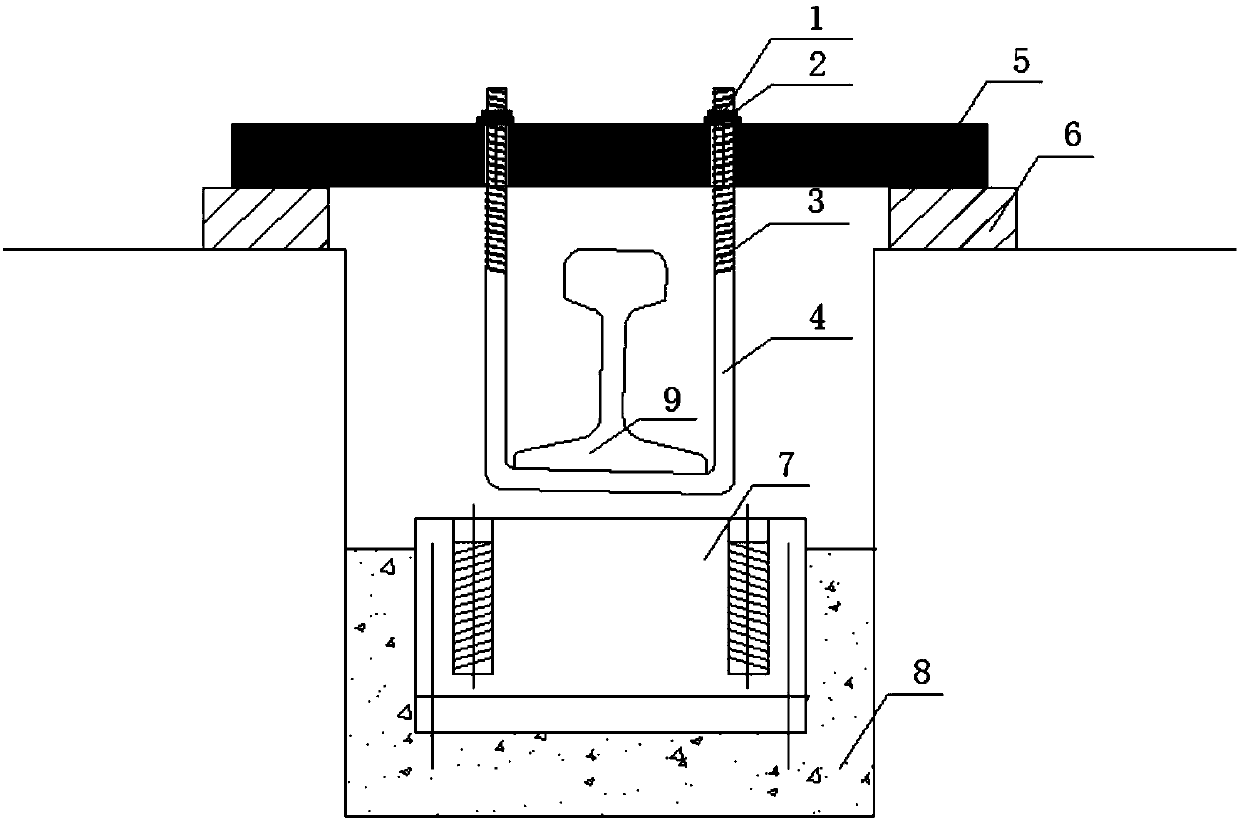

[0034] See figure 1 In the subway depot, the reserved groove of the monolithic track bed is generally divided into a left-strand groove and a right-strand groove. The width of the reserved groove is 420mm and the depth is 450mm. The construction of the reserved groove is completed by the early civil construction unit; The new and old concrete is better bonded. The surface and bottom of the reserved groove are treated. Before the rail is placed in the groove, the concrete is poured in the reserved groove for chipping treatment, and at the same time between the two short sleeper blocks at the bottom of the reserved groove Plant 2 expansion bolts, the length of the expansion bolt is 200mm, the diameter is 20mm, and it is implanted in the concrete at the bottom of the reserved groove 100mm. After cleaning the garbage in the groove, apply the concrete interface agent before pouring the concrete, such as Image 6 , 7 Shown.

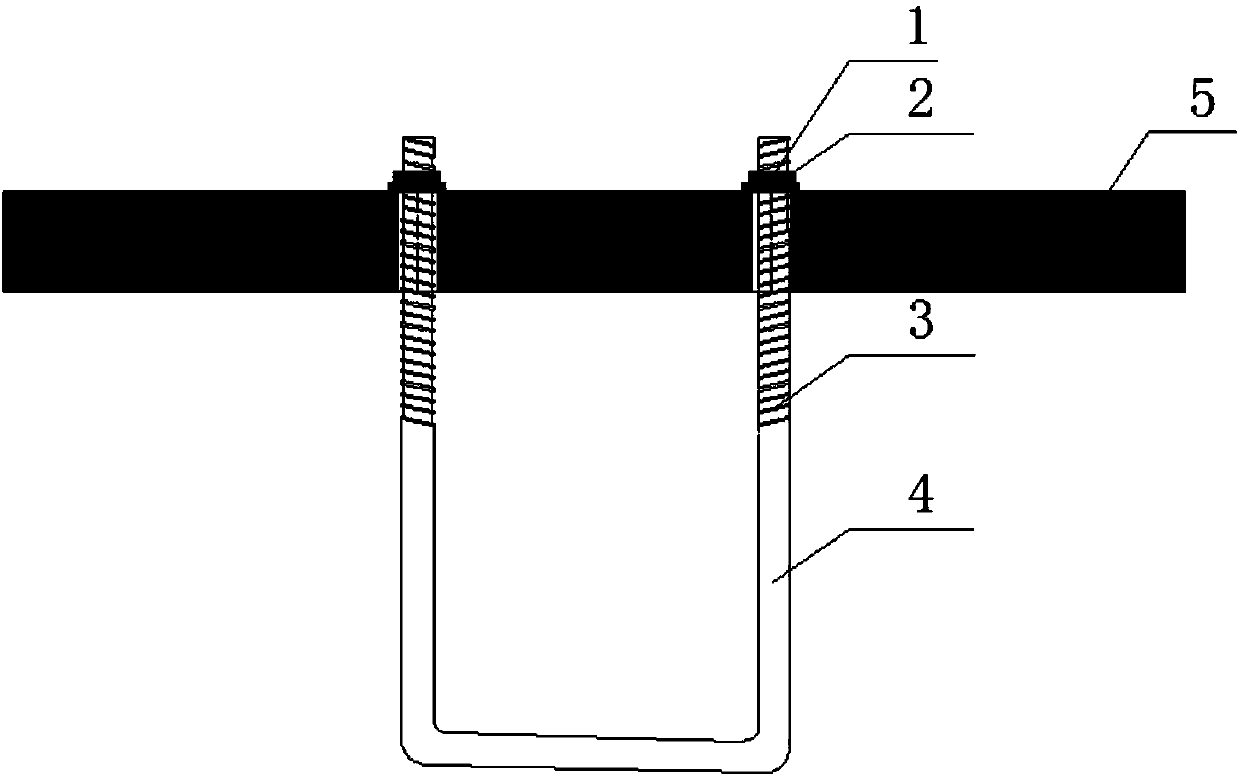

[0035] See figure 2 , The fixing devices used in the constru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com