Combined leakage stoppage mat

A combined leaky gasket technology, which is applied in the direction of ships, ship safety, transportation and packaging, etc., can solve the problems that the thread fit cannot be rotated, the plugging soft pad cannot be compressed, and the plugging fails, etc., so as to facilitate maintenance Effects of replacement, improvement of durability and ease of operation, and enhancement of applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation of the present invention will be described in detail below in conjunction with preferred embodiments.

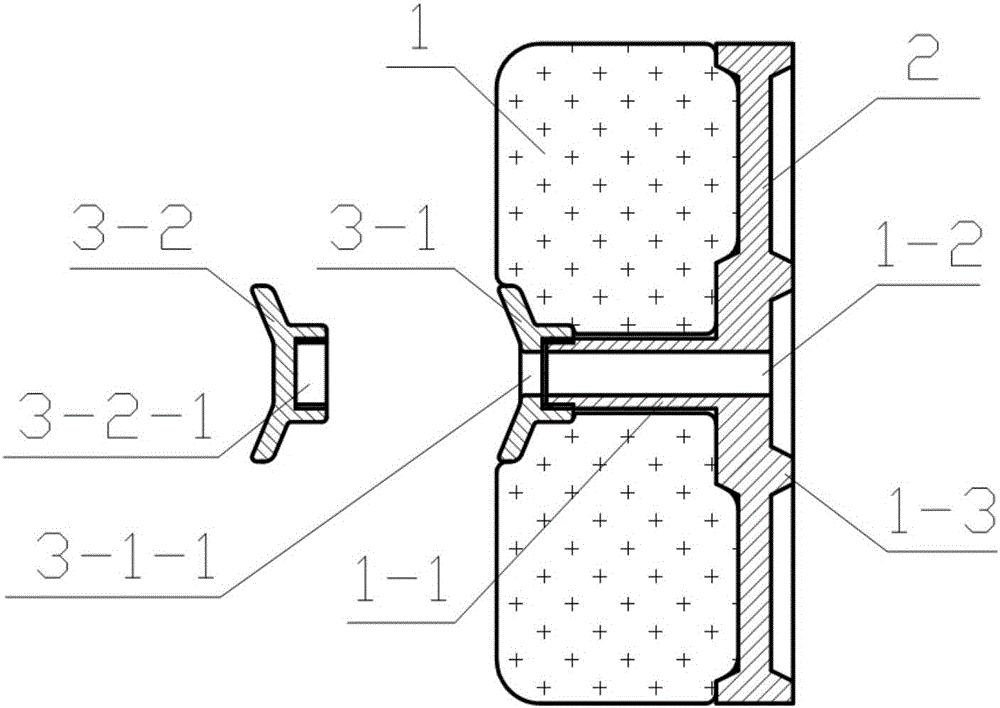

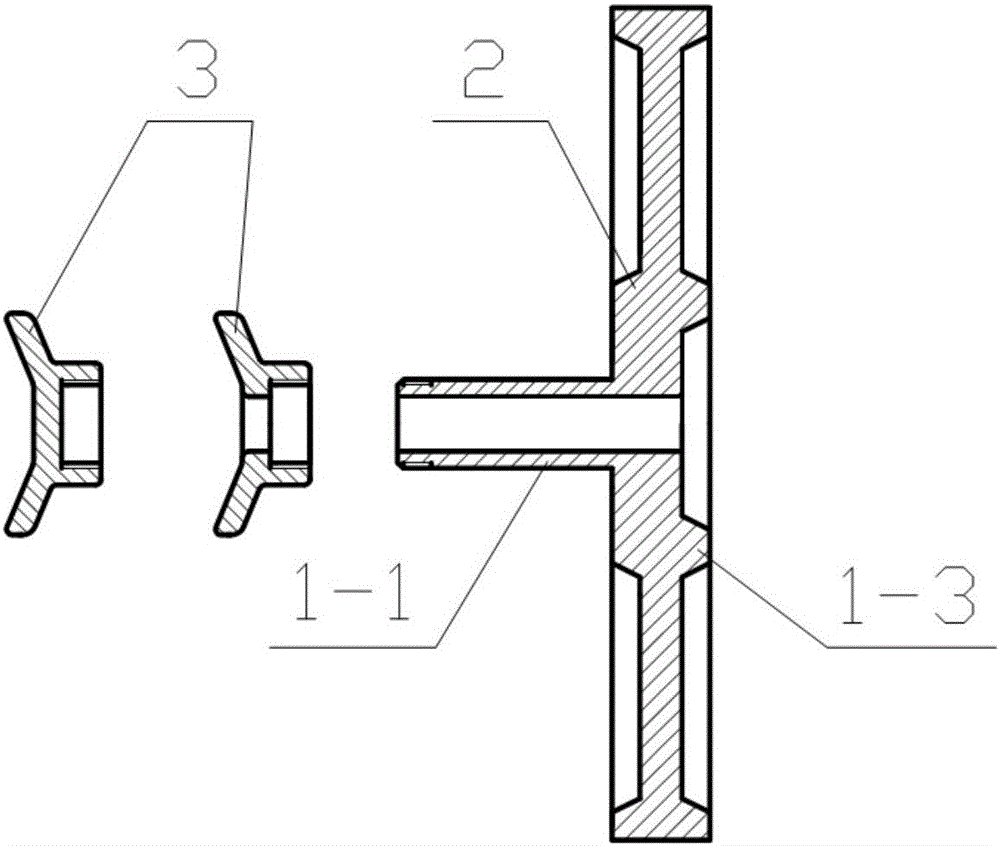

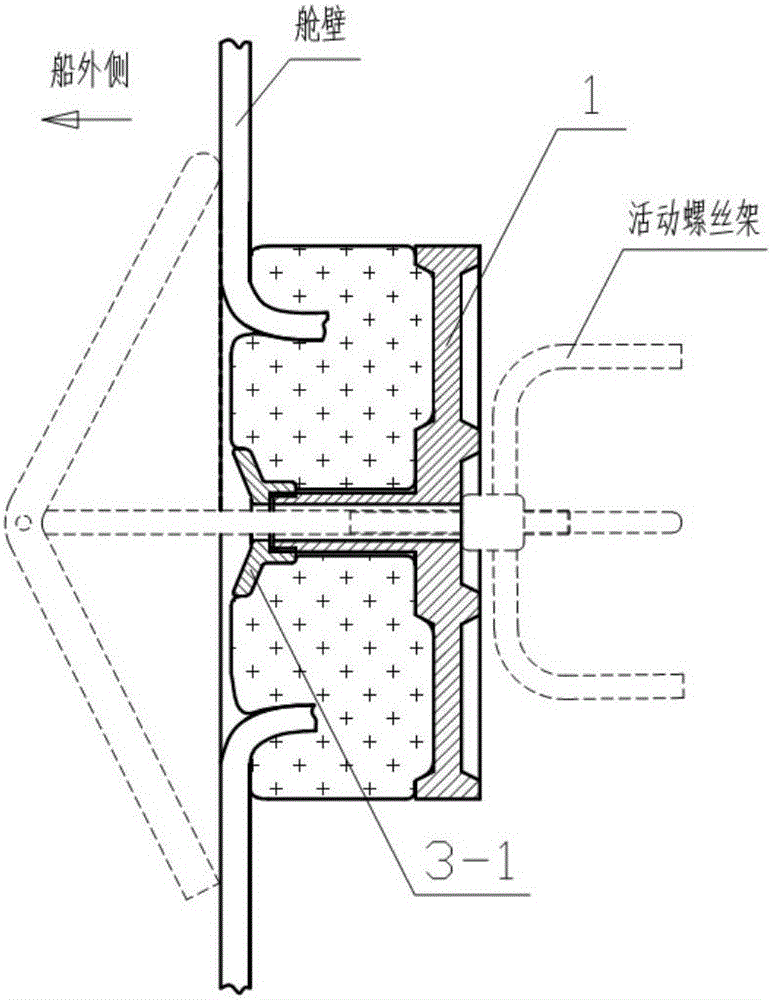

[0018] See the accompanying drawings for details. This embodiment provides a combined plugging pad, including a plugging soft pad 1, a plugging backing plate 2 and an end cover 3. The leak plugging backing plate is used as a support to compress the plugging soft pad. The shape of the plugging backing plate is a circular thin plate with a round hole in the center and a flange on the periphery, and a ring-shaped reinforcing rib 1-3 in the center of the outer side. The inside of the plugging backing plate is provided with a stepped convex shaft 1-1, and its cross-sectional shape is an inverted T shape. The plugging backing plate is provided with a central round hole 1-2, and the plugging pad is used to seal the broken hull. It is a circular plugging pad with a hole in the center, which is recommended to be made of canvas and filled with lint, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com