Ball screw pre-stretching mechanism and pre-stretching method

A ball screw and ball screw pair technology, applied in metal processing machinery parts, metal processing equipment, maintenance and safety accessories, etc., can solve problems such as precision decline, improve long-term retention, fast response, and improve work reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings, and the aforementioned and other objects, features, aspects and advantages of the present invention will become more apparent, so that those skilled in the art can implement them with reference to the description.

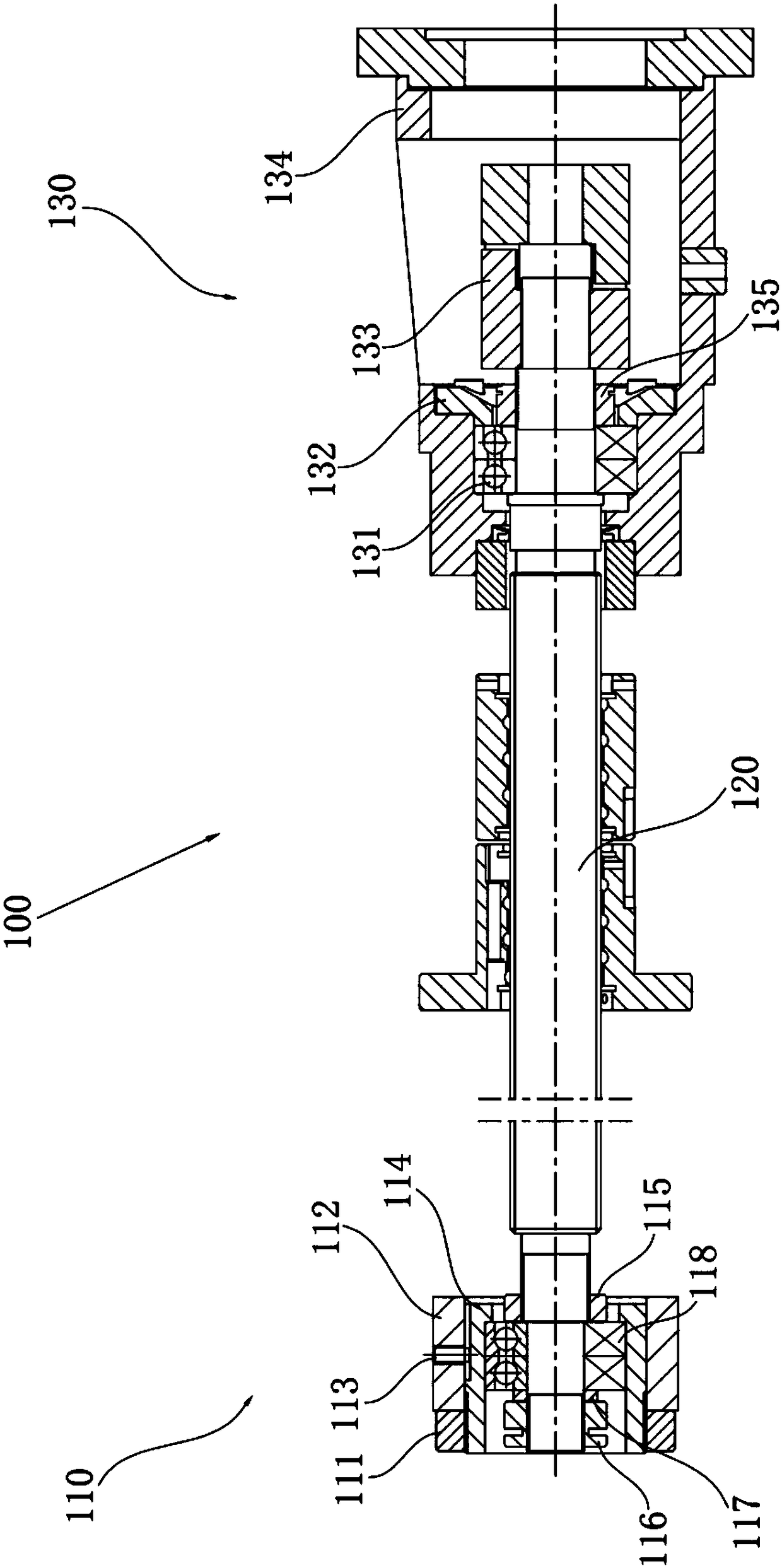

[0031] refer to figure 1 , the ball screw pre-tensioning mechanism 100 includes: a rear locking assembly 110, a ball screw pair 120, and a front locking assembly 130, wherein the front locking assembly 130 and the rear locking assembly 110 are respectively sleeved on the ball screw The front end and the rear end of the pair 120, and the front end and the rear end of the ball screw pair 120 are respectively fixed by the front locking assembly 130 and the rear locking assembly 110. The rear end bearing 118 on the screw pair 120, the rear end bearing sleeve 114, and the rear end bearing seat 112, the rear end bearing sleeve 114 is also set with a tensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com