Vacuum freeze-drying processing technology for green asparagus

A technology of vacuum freeze-drying and processing technology, which is applied in food drying, preservation of fruits/vegetables through freezing/refrigeration, food preservation, etc. It can solve the problems of low technical content, high production cost, perishable deterioration, etc., and achieve cost reduction, Easy to transport and good storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

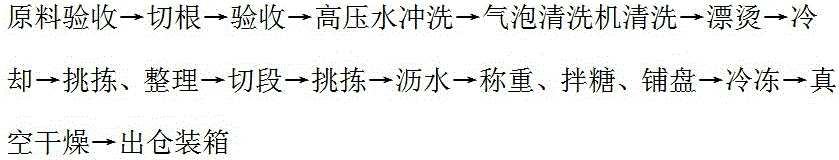

Method used

Image

Examples

Embodiment 1

[0035] Raw material acceptance: the diameter is required to be 3-8mm, no rotten ends, no rust spots, no thick fibers, etc. On the table, manually use a kitchen knife to cut off mud roots, white roots, rotten heads and serious purple roots, and pick out various impurities such as silk threads, grasses, hairs, etc.; pay attention to the plastic ropes that bind asparagus must not be mixed into the product; the diameter> 8mm asparagus requires cutting with a knife. Special inspection is carried out on the desktop to remove unqualified products such as mud roots, white roots, and rotten heads, as well as various residual foreign impurities. If the unqualified products are serious, they will be returned for rework. After acceptance, the asparagus is first washed with high-pressure water to remove a large amount of sediment on its surface, then soaked in multiple pools and manually scrubbed several times, and the water is changed more frequently, and the bubble cleaner is cleaned. P...

Embodiment 2

[0037] Raw material acceptance: the diameter is required to be 3-8mm, no rotten ends, no rust spots, no thick fibers, etc. On the table, manually use a kitchen knife to cut off mud roots, white roots, rotten heads and serious purple roots, and pick out various impurities such as silk threads, grasses, hairs, etc.; pay attention to the plastic ropes that bind asparagus must not be mixed into the product; the diameter> 8mm asparagus requires cutting with a knife. Special inspection is carried out on the desktop to remove unqualified products such as mud roots, white roots, and rotten heads, as well as various residual foreign impurities. If the unqualified products are serious, they will be returned for rework. After acceptance, the asparagus is first washed with high-pressure water to remove a large amount of sediment on its surface, then soaked in multiple pools and manually scrubbed several times, and the water is changed more frequently, and the bubble cleaner is cleaned. P...

Embodiment 3

[0039]Raw material acceptance: the diameter is required to be 3-8mm, no rotten ends, no rust spots, no thick fibers, etc. On the table, manually use a kitchen knife to cut off mud roots, white roots, rotten heads and serious purple roots, and pick out various impurities such as silk threads, grasses, hairs, etc.; pay attention to the plastic ropes that bind asparagus must not be mixed into the product; the diameter> 8mm asparagus requires cutting with a knife. Special inspection is carried out on the desktop to remove unqualified products such as mud roots, white roots, and rotten heads, as well as various residual foreign impurities. If the unqualified products are serious, they will be returned for rework. After acceptance, the asparagus is first washed with high-pressure water to remove a large amount of sediment on its surface, then soaked in multiple pools and manually scrubbed several times, and the water is changed more frequently, and the bubble cleaner is cleaned. Pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com