Rectangular linear variable optical filter manufacturing method and device

A linear gradient filter, filter technology, applied in the direction of filters, etc., can solve the problems of complicated production process, poor precision of rectangular linear gradient filter, unstable quality, etc., to improve quality stability and shorten the time. The effect of trial plating time and improving linear dispersion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

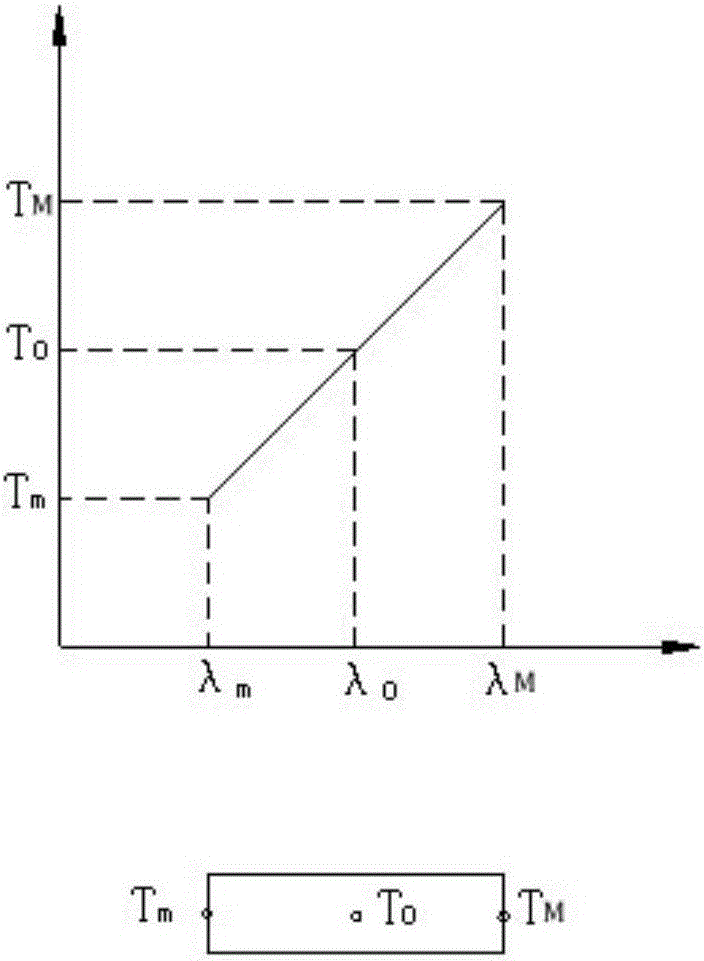

[0085] The basic parameters of the target rectangular linear gradient filter: the length of the gradient film L=50mm, the angle of incidence AOI=0 degrees, the center wavelength is 550nm, and the transmittance increases from 20% to 80% along the length of the gradient film, showing a linear change.

[0086] (1) Choose K9 glass or fused silica FS as the glass substrate, the length of the coating surface is 50mm, and the coating surface and its opposite surface are all polished;

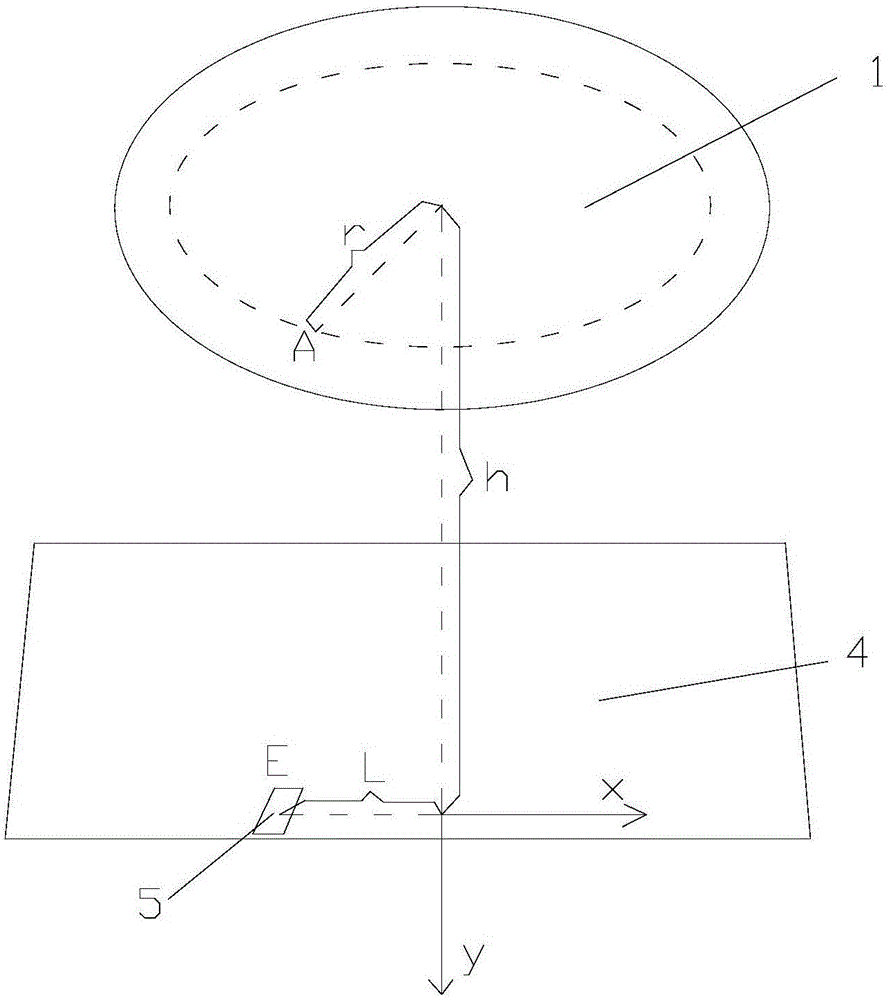

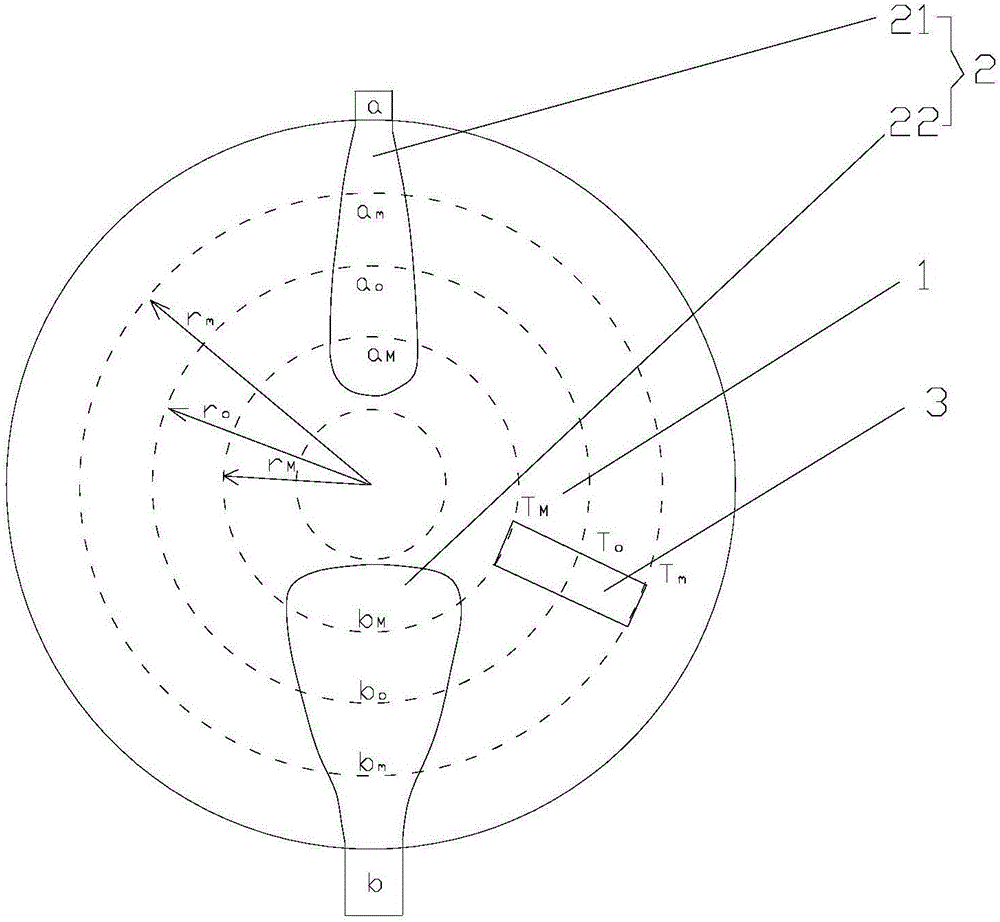

[0087] (2) Select the DMD-450 coating machine produced by Beijing Instrument Factory, such as figure 1 As shown, the workpiece disk is a flat circular fixture that rotates around the center, and its diameter is 400mm. The vertical distance L from the evaporation source to the center of the workpiece disc is 150mm, the vertical height h from the center of the workpiece disc to the bottom plate of the evaporation source is 380mm, and the workpiece disc is rotated by the edge bearing at a speed of 20r / min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com