Integrated profile controlling and flooding injection system

An injection system, control and flooding technology, which is applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of high use cost, high operating cost of the control and drive injection system, and high consumption of equipment wearing parts, etc. Achieve the effect of solving heat dissipation problems, reducing program confusion, and facilitating operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

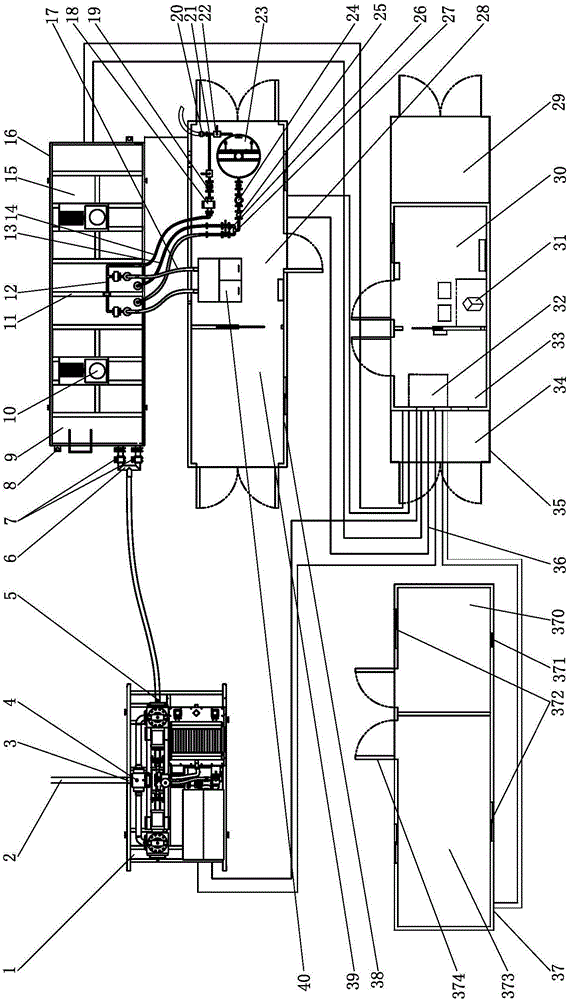

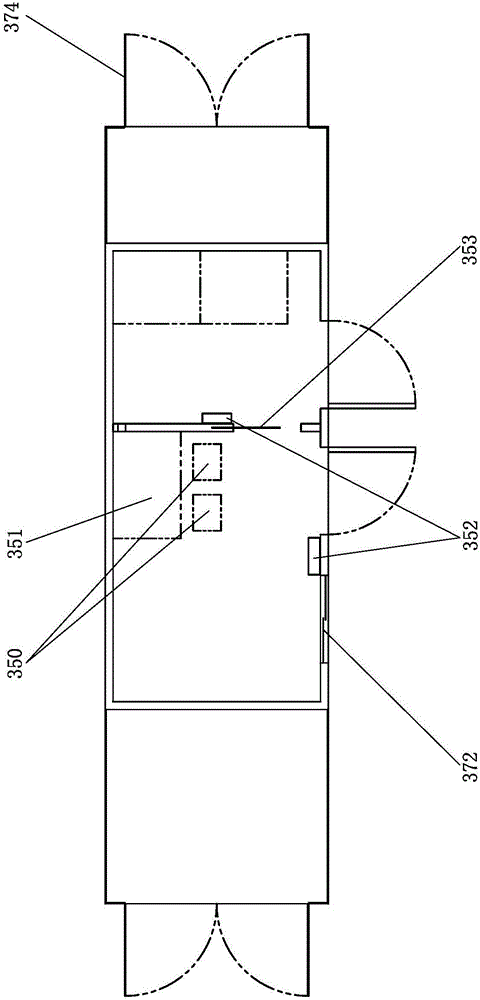

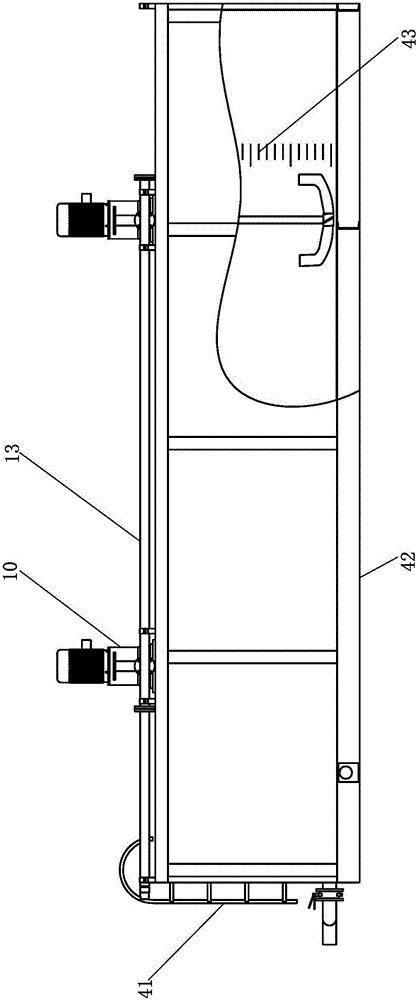

[0030] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described and illustrated in further detail:

[0031] see figure 1 —4: An integrated flood control and injection system, which is mainly composed of a solution stirring tank 16, a material feeding room 38, a control room 35, a profile control injection pump 1, a central control cabinet 32 and a living room 37. The solution stirring tank 16 is divided into tank a9 and tank b15 by a partition 11, a slurry outlet manifold 6 is installed at the front end, a slurry inlet manifold 12 and an agitator 10 are installed at the top, and a liquid level sensor 8 is installed at the front and rear ends respectively; The feeding room 38 is divided into a feeding area 28 and a material storage area 39, and the feeding area 28 is provided with a high-pressure incoming water manifold, a crosslinking agent adding assembly 27, and a powder conveying device 40; the control room 35 is divide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com