Gap grouting device capable of removing dust and achieving damping

A technology of gaps and connecting devices, which can be used in construction and building construction, etc., and can solve problems such as difficulty in pouring quality and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

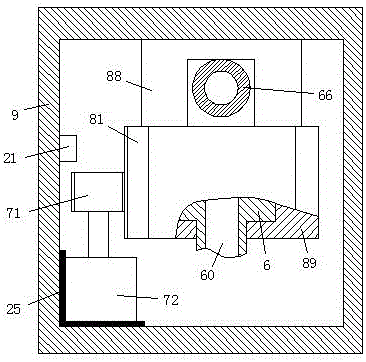

[0008] Combine below Figure 1-2 The present invention will be described in detail.

[0009] A dust-removing and shock-absorbing gap grouting device according to an embodiment of the present invention is used for grouting building gaps 1, including a base frame 9 and a spray head connected to the rear wall of the base frame 9 through a rotating support device 88 The connection device 8, wherein the nozzle connection device 8 includes a nozzle rotation drive housing 89 with a sliding clamping cavity 80, and the nozzle movement driving slider 6 is slidably fitted in the sliding clamping cavity 80. A fluid channel 60 extending in the forward and backward direction is provided in the movement driving slider 6 for fluid communication with the grouting nozzle 66 , and the upper side of the nozzle movement driving slider 6 passes the top pressure provided in the sliding clamping cavity 80 . The spring 83 is subjected to a pressing effect so that the pressing roller 62 at the end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com