Novel boxing machine

A cartoning machine, a new type of technology, applied in the field of packaging, can solve the problems of degumming, unsuitable for long-distance transportation, large labor demand, etc., and achieve the effect of small footprint and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

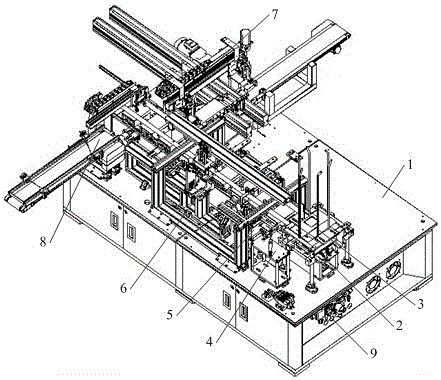

[0038] A kind of novel cartoning machine provided by the present invention, such as figure 1 As shown, the frame 1 is provided with a fence-type conveying line module 2, a box opening module 3, an ear folding module 4, a double-sided adhesive tearing release paper module 5, a forming positioning module 6, an assembly Entry module 7, bad discharge module 8, the box opening module 3 is located at the front end of the fence type conveying line module 2, ear folding module 4, double-sided adhesive tear release paper module 5, forming positioning mold Group 6 is sequentially set on one side of the fence-type conveyor line module 2, the loading module 7 is located on the other side of the fence-type conveyor line module 2 and behind the forming positioning module 6, and the defective discharge module 8 is set After packing into the module 7, it is located on the same side of the barrier type conveying line module 2 as the forming positioning module 6.

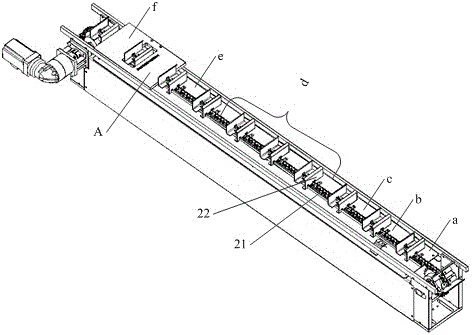

[0039] The fence-type convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com