Polystyrene receiving bin

A technology of polystyrene and blanking bins, which is applied in the field of devices for making EPS extruded boards. It can solve the problems of being unable to buffer the expansion stress of materials, not being able to see materials, and large prestress, so as to achieve light weight and prevent materials from floating. The effect of flying and eliminating expansion stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

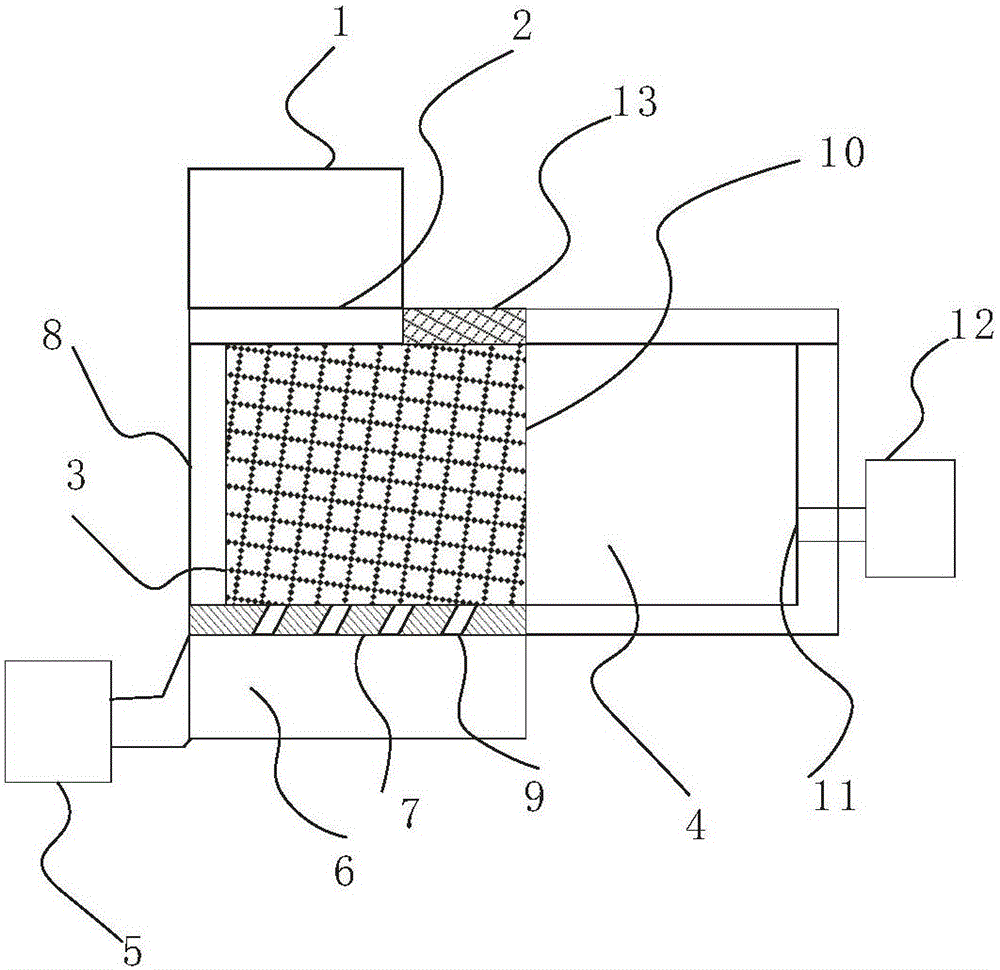

[0011] As shown in the figure, a polystyrene blanking bin includes a protective screen 1 at the outlet of the mixing tank and a bin body, the bin body includes a buffer bin 3 and is arranged along the extension direction of the buffer bin and communicates with the buffer bin 3 The feeding bin 4 of the mixing tank, the protective screen 1 of the outlet of the stirring tank is a mesh box including a discharging opening (not shown) connected with the mixing tank and a blanking opening 2 connected with the buffer bin 3, so The buffer bin 3 includes a buffer bin bottom plate 7, a buffer bin upper protective screen 13, a buffer bin side protective screen 10 and a buffer bin observation window 8 arranged at the opposite end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com