A new wheel hub manual surface drawing machine

A technology of wire drawing machine and wheel hub, which is applied in the field of new wheel hub manual surface drawing machine, can solve the problems of inability to guarantee the quality of wheel hub wire drawing and unstable force, and achieve the effect of satisfying product shape and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

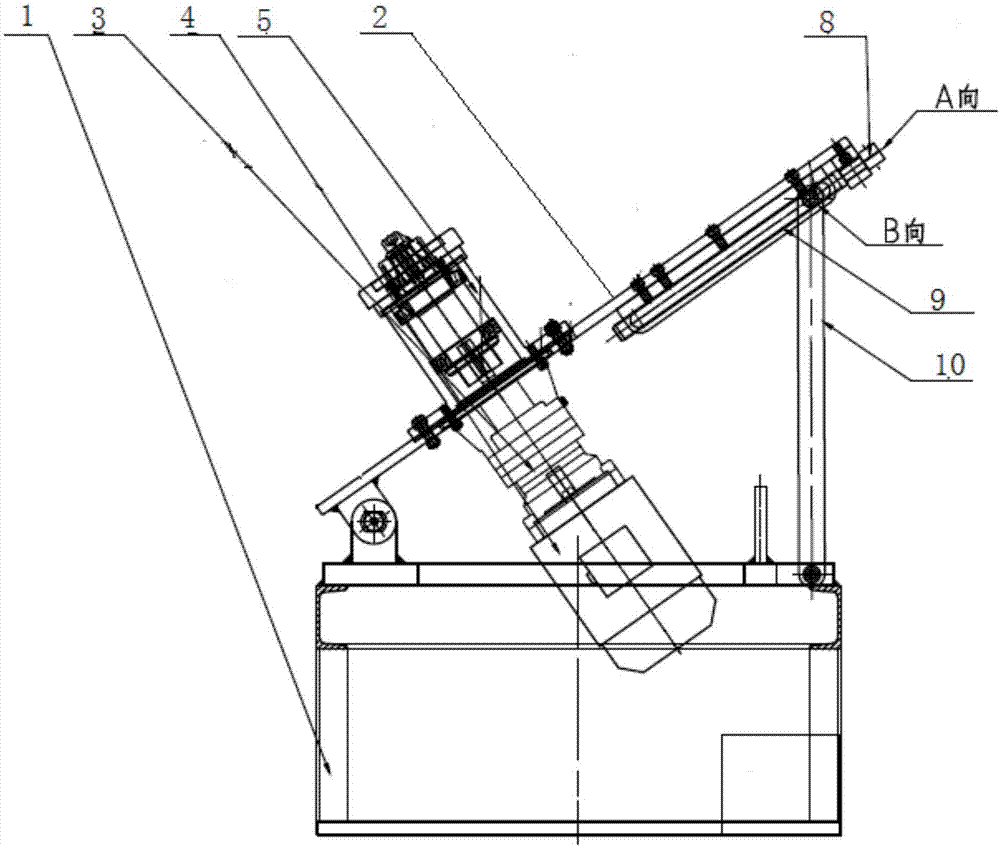

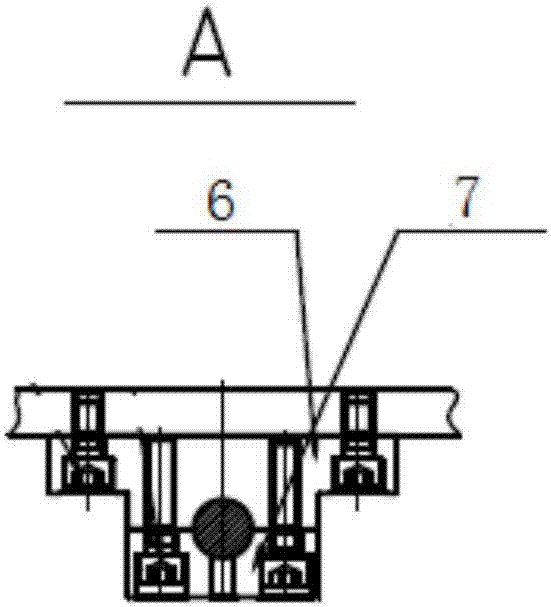

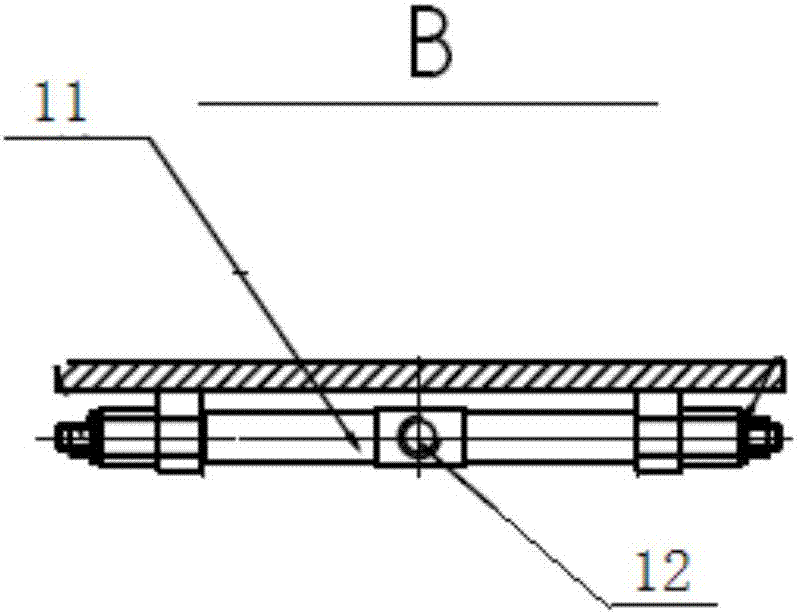

[0031] see Figure 1 to Figure 8 :

[0032] A new wheel hub manual surface drawing machine, including a bracket 1, a rotating plate 2, a reducer 3, a motor 4, a rotating shaft combination 5, a transmission shaft fixing base 6, a transmission shaft tight seat 7, a transmission shaft 8, a chute 9, and a crank Rod 10, rotating plate sliding shaft 11, rotating plate sliding shaft stop ring 12;

[0033] The reducer 3 is mounted on the output shaft end of the motor 4, the rotating plate 2 is hingedly mounted on the support 1, and the reducing device 3 and the motor 4 are connected with the rotating plate 2 as a whole by bolts. ;

[0034] The rotating shaft 5-2 in the rotating shaft combination 5 is connected with the output shaft of the reducer 3 through a flat k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com