Boai ginger massecuite and production method thereof

A technology of huaijiang massecuite and huaijiangmu, which is applied in confectionary, confectionary industry, cocoa, etc., can solve problems such as difficult production experience, communication, and restrictions on the development and progress of huaijiang massecuite, and achieve easy operation and easy mastery , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

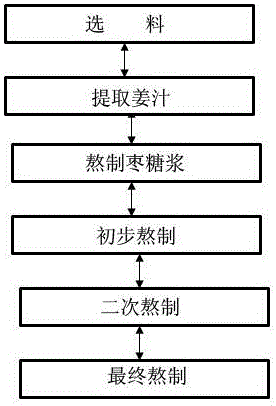

Image

Examples

Embodiment 1

[0021] The Huaijiang sugar paste is prepared from the following components according to weight percentage: 30% of Huaijiang mother, 10% of jujube, 7% of honey, 5% of wolfberry, and the balance is brown sugar.

[0022] In this embodiment, the storage time of the described Huaijiangmu, Jujube and Lycium barbarum is not more than 1 year.

[0023] A preparation method of Huaijiang sugar paste, comprising the following steps:

[0024] The first step is to select materials, choose fully mature, full-bodied, uniform structure, no disease and mildew, and then wash with deionized water at a temperature of 20°C and spread the surface water in the shade share;

[0025] The second step is to extract ginger juice. After the material selection in the first step, the Huai Jiangmu is squeezed through a juicer to obtain fresh ginger juice and fresh ginger residue, and the fresh ginger juice and fresh ginger residue are 0 ℃ low temperature storage, wherein the diameter of ginger residue parti...

Embodiment 2

[0031] The Huaijiang sugar syrup is prepared from the following components according to weight percentage: 25% of Huaijiang mother, 8% of jujube, 8% of honey, 10% of medlar, and the balance is brown sugar.

[0032] In this embodiment, the storage time of the described Huaijiangmu, Jujube and Lycium barbarum is not more than 1 year.

[0033] A preparation method of Huaijiang sugar paste, comprising the following steps:

[0034] The first step is to select materials, choose fully mature, full-bodied, uniform structure, no disease and mildew, and then wash with deionized water at a temperature of 15°C and spread the surface water in the shade share;

[0035] The second step is to extract ginger juice, and the Huai Jiangmu after the first step of material selection is squeezed through a juicer to obtain fresh ginger juice and fresh ginger residue, and the fresh ginger juice and fresh ginger residue are subjected to- Store at a low temperature of 10°C, and the diameter of the gin...

Embodiment 3

[0041] The Huaijiang sugar paste is prepared from the following components according to weight percentage: 25% of Huaijiang mother, 8% of jujube, 6% of honey, 7% of wolfberry, and the balance is brown sugar.

[0042] In this embodiment, the storage time of the described Huaijiangmu, Jujube and Lycium barbarum is not more than 1 year.

[0043] A preparation method of Huaijiang sugar paste, comprising the following steps:

[0044] The first step is to select materials, choose fully mature, full-bodied, uniform structure, no disease and mildew, and then wash with deionized water at a temperature of 15°C and spread the surface water in the shade share;

[0045] The second step is to extract ginger juice, and the Huai Jiangmu after the first step of material selection is squeezed through a juicer to obtain fresh ginger juice and fresh ginger residue, and the fresh ginger juice and fresh ginger residue are subjected to- Store at low temperature at 5°C, and the diameter of the ging...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com