Automatic sampling device

A technology of automatic sample injection and injection valve, which is applied in measurement devices, instruments, scientific instruments, etc., can solve the problems affecting the accuracy of sample analysis and detection, long liquid flow paths, and many instruments and equipment, and achieves low cost and few instruments and equipment. , the effect of high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

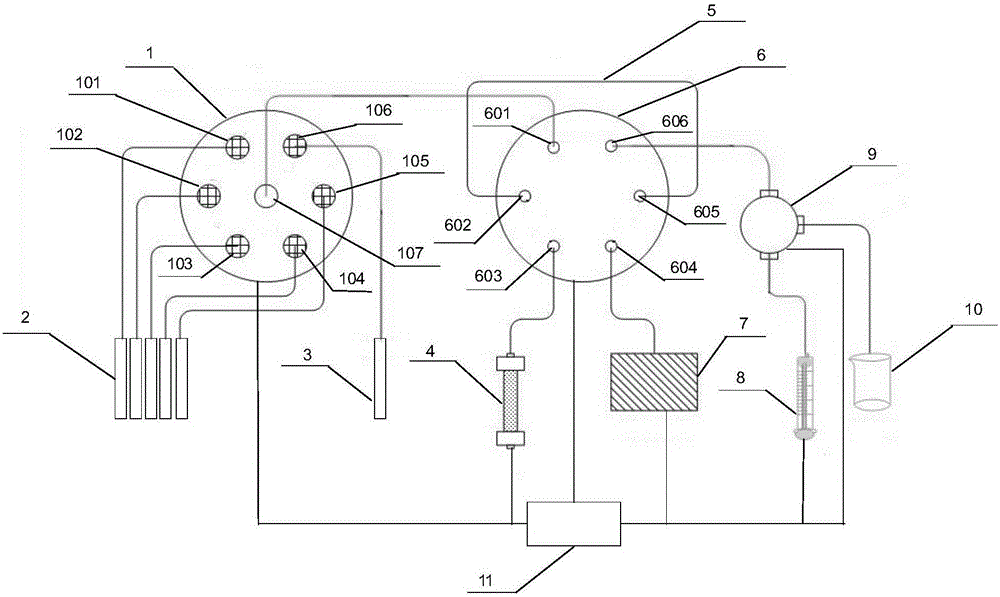

[0032] Such as figure 1 As shown, an automatic sampling device includes a channel selection valve 1, a sampling valve 6, a syringe pump 8 and an electric control mechanism 11;

[0033] The electronic control mechanism 11 single-chip interface and the channel selection valve control motor, the sampling valve control motor, through the interface and the single-chip computer online, the single-chip output signal controls the operation of the corresponding motor, and realizes the control of the channel selection valve, sampling valve and sampling pump ;

[0034] The channel selection valve 1 includes 6 input channels and 1 output channel, respectively 101-107, wherein the channels 101-105 are sample channels, which are respectively connected to the corresponding sample bottles 2, and the channel 106 is a cleaning channel, which is connected with the cleaning channel. The bottle 3 is connected, and the channel 107 is an output channel, which is connected to the sampling valve 6. T...

Embodiment 2

[0045] Adopt the automatic sampling device of embodiment 1 to carry out sample loading, comprise the steps:

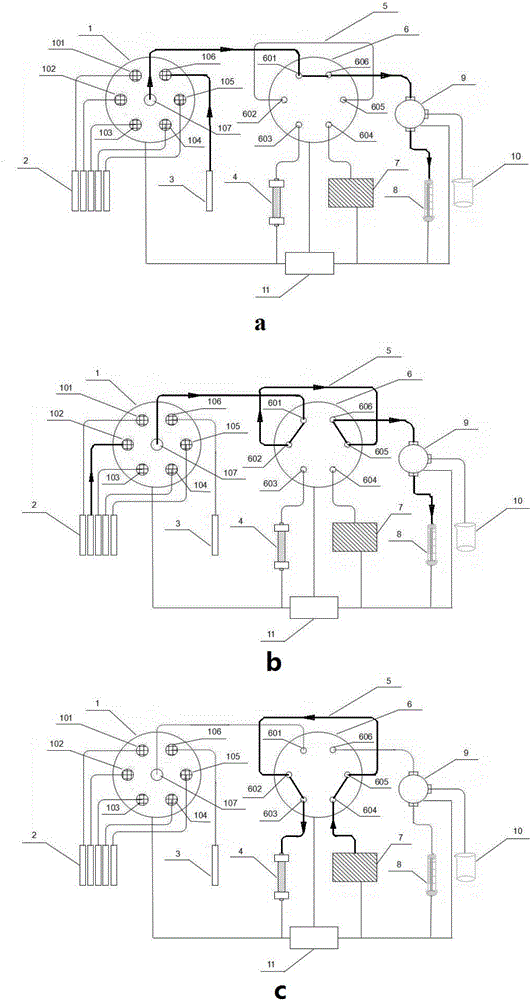

[0046] (1) cleaning

[0047] Before sample injection, the pipeline of the sample injection system needs to be cleaned, and the quantitative loop 5 is in communication with the separation flow channel at this time. The electronic control mechanism 11 is connected to the single-chip microcomputer through the interface of the single-chip microcomputer, and controls the switching channel selection valve 1 and the channel of the sampling valve 6, wherein the channels 106 and 107 are connected, and the channels 601 and 606 are connected, and the sampling pump 8 starts the suction action, and the cleaning solution is sucked The common pipeline of the six-way sampling valve 1 is then sucked into the syringe pump 8 through the channel 601 of the six-way sampling valve through 606 through the three-way valve 9, so as to achieve the purpose of cleaning the common pipeline and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com