A method and device for automatic positioning and pointing of a concrete rebound tester

An automatic positioning and rebound hammer technology, applied in the field of measurement, can solve the problems of time-consuming, labor-intensive efficiency, low efficiency, and difficulty in ensuring the standardization of the measurement process, and achieve the effects of high measurement efficiency, improved accuracy, and standardized measurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for automatic positioning and dotting of a concrete rebound hammer, which is to first set a movement trajectory to connect 16 measuring points in a measurement area in series, and then control the rebound hammer to move along the set movement trajectory, so that the rebound hammer moves To a measuring point is to realize the positioning of the measuring point. After positioning the measuring point, the rebound value of the positioned measuring point is measured by controlling the rebound hammer. After the measurement of the measuring point is completed, the rebound hammer Continue to move to the next measuring point for measurement until the measurement of all 16 measuring points in the survey area is completed.

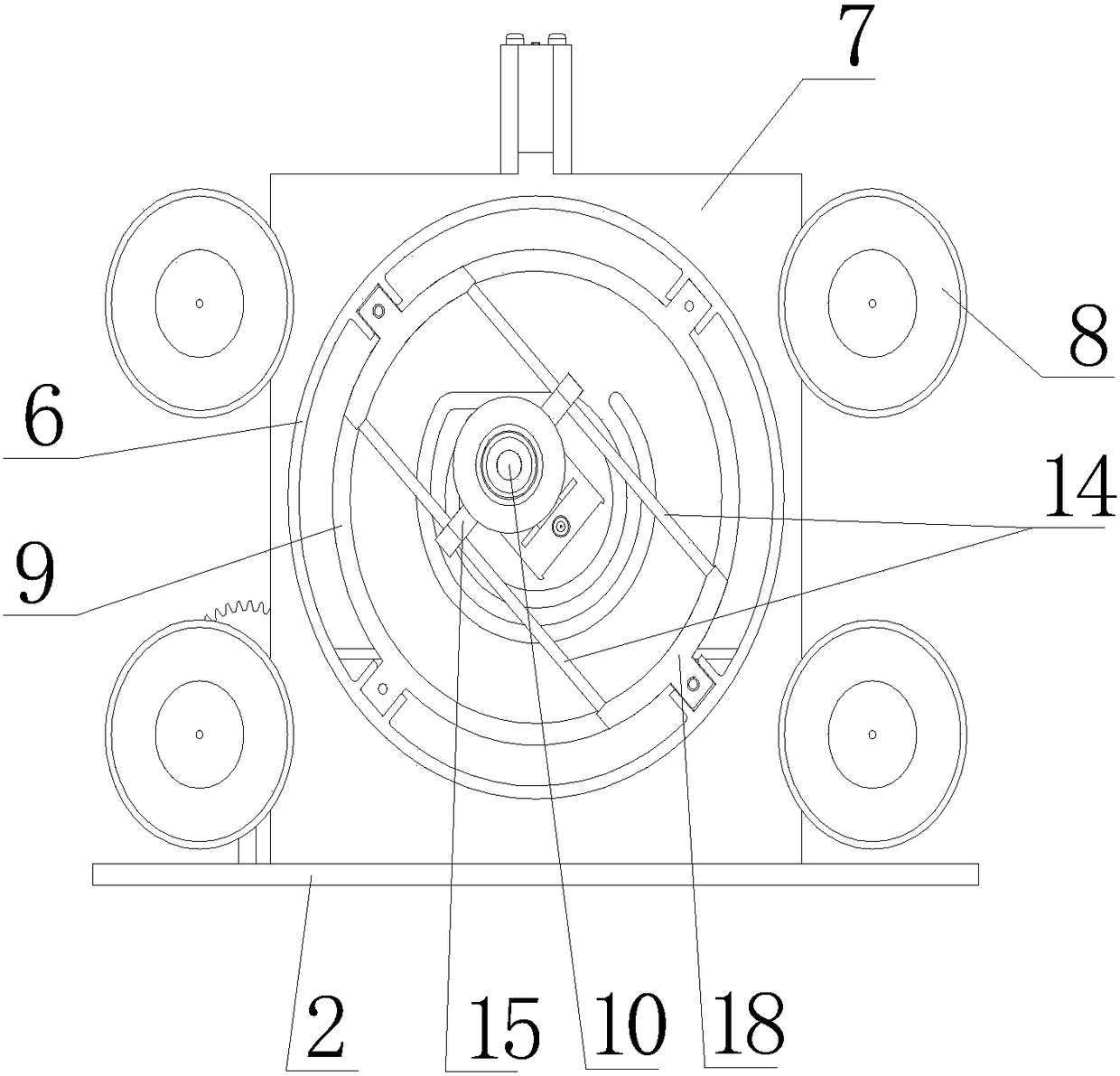

[0029] Usually, 16 survey points in each survey area are distributed on three concentric circles (as shown in the attached Figure 9 shown), in order to facilitate the realization of control, it is preferable that the motion track is similar to a plan...

Embodiment 2

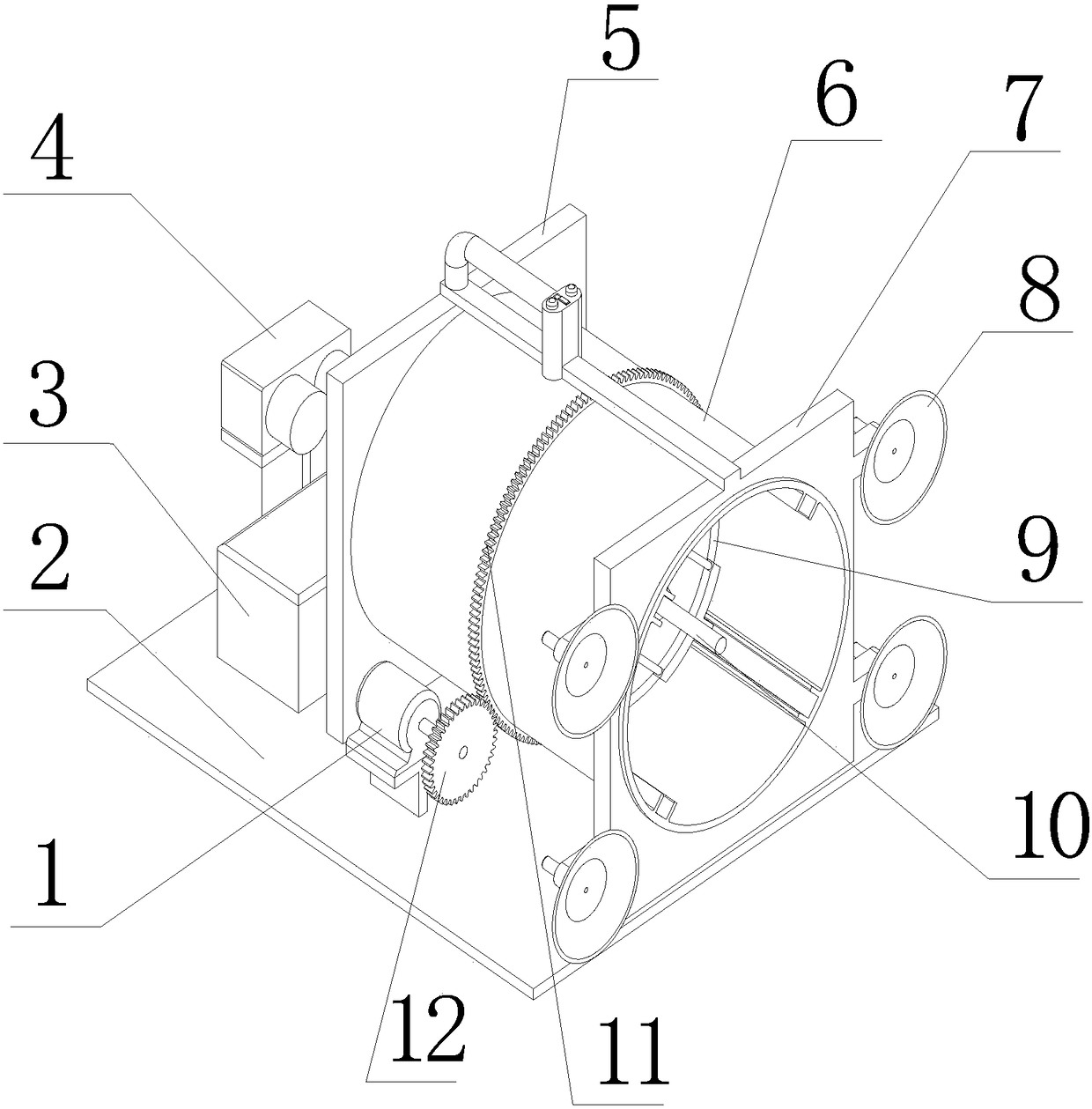

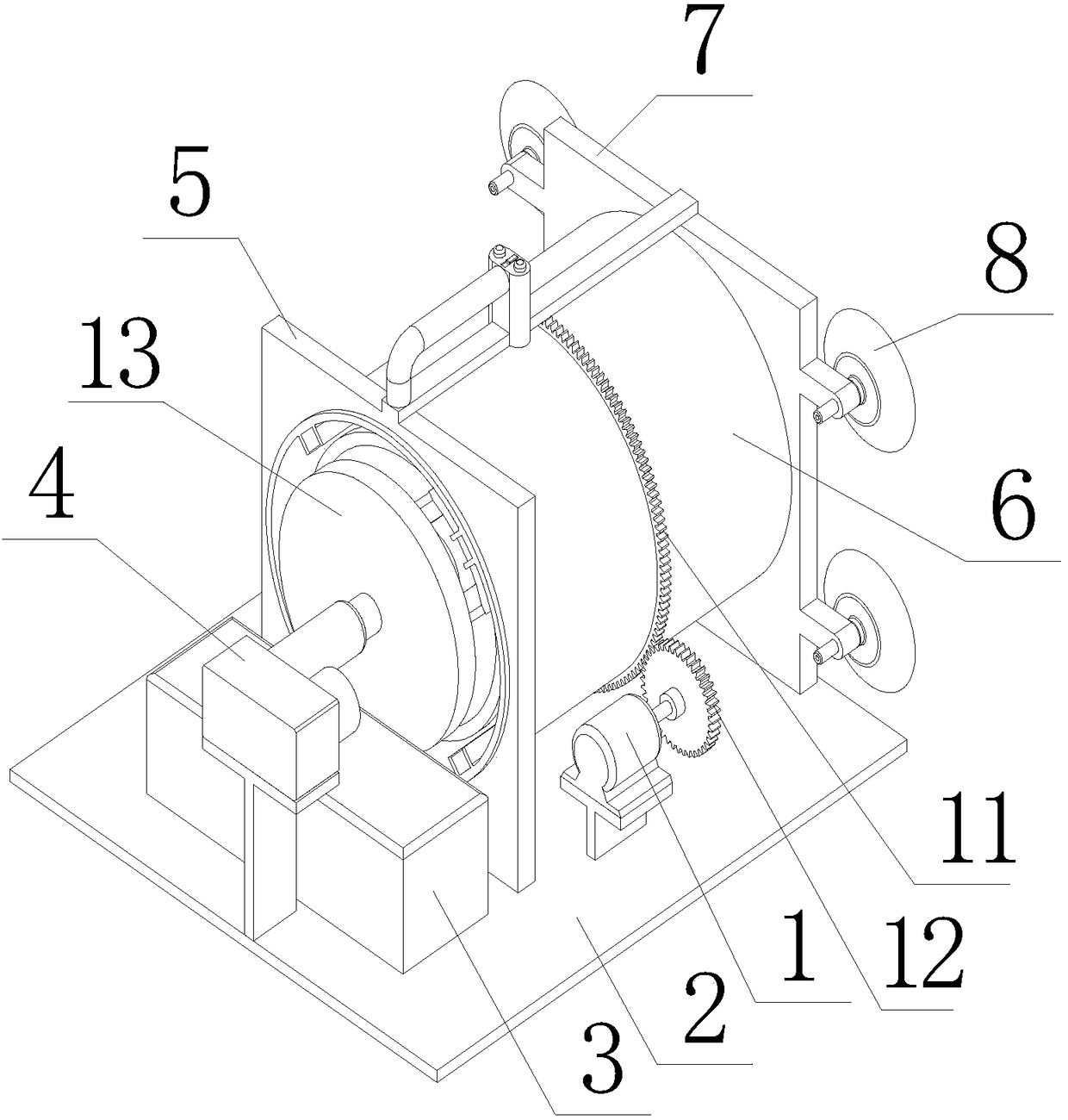

[0031] As shown in the accompanying drawings, an automatic positioning and dotting device for a concrete rebound hammer includes a frame 2, a rebound hammer 10, an automatic positioning mechanism, a dotting mechanism, and a control box 3. Wherein, the front end of the frame 2 is fixed with a vertical plate I7, the rear end of the frame 2 is fixed with a vertical plate II5, and the front end of the vertical plate I7 is equipped with four suction cups 8 . The automatic positioning mechanism includes a stepping motor 1, an outer cylinder 6, and an inner cylinder 9. The outer cylinder 6 is rotatably installed between the vertical plate I7 and the vertical plate II5. The outer cylinder 6 has a ring gear 11, The stepper motor 1 is installed on the frame 2, and the stepper motor 1 is engaged with the ring gear 11 outside the outer cylinder 6 through the gear 12 connected to its output end, and the outer cylinder 6 can be driven to rotate by the stepper motor 1 . The inner cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com