Intelligent variable-stiffness tuned mass damper system with magnetorheological elastomer bearings

A technology of tuning mass damping and magneto-rheological elasticity, which is applied in the direction of magnetic springs, springs/shock absorbers, springs, etc., can solve the problems of high manufacturing costs, maintenance costs, and high usage costs, and achieve improved adjustment range, reduced size, and reduced The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

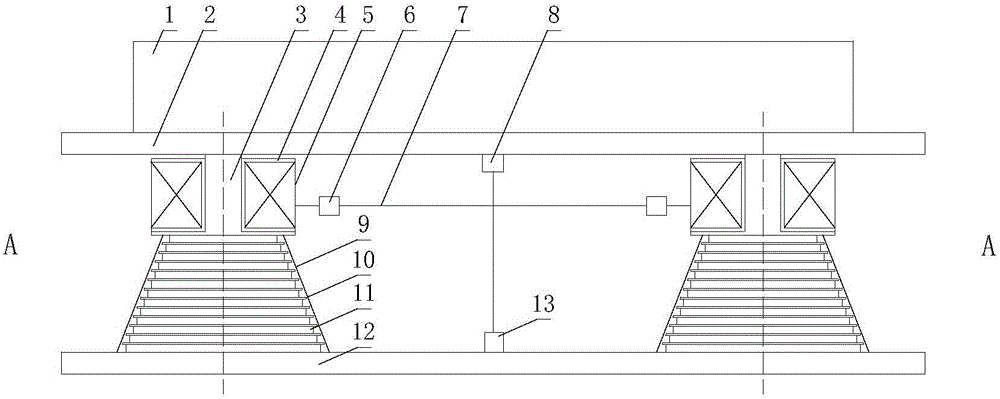

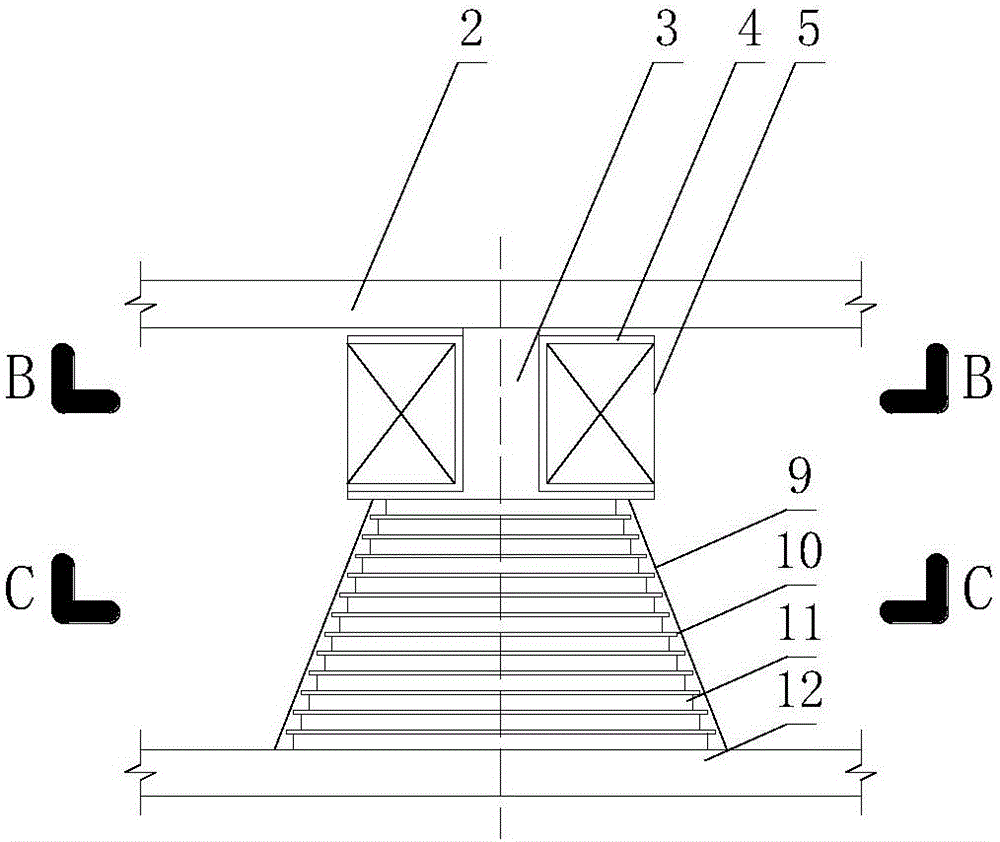

[0022] The specific embodiment of the present invention sees Figure 1 to Figure 6 . by floor plan figure 1 and A-A sectional schematic diagram figure 2 It can be seen that this embodiment consists of 1 fast tuning mass 1, 1 upper connecting plate 2, 4 magnetorheological elastomer bearings, 4 excitation components, 2 magnetically conductive connecting plates 12, 2 sensors 8, 13, The signal line 7 is composed of a controller 6 . The tuning mass 1 of the system is fixed on the upper connection plate 2, and the upper connection plate 2 is connected with the iron core 3 of the excitation assembly. The iron cores 3 of the four excitation components of the system are welded with steel plates up and down, and the coils 5 are wrapped on the iron cores 3 after being wrapped by a heat-insulating hard insulating layer 4 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com