Fuel saving device for six-cylinder diesel automobile engine

A diesel vehicle and engine technology, applied in engine control, machine/engine, mechanical equipment, etc., can solve the problems of increased transportation costs, hidden dangers of driving safety, high fuel consumption, etc., and achieve the effect of reducing operating costs and improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

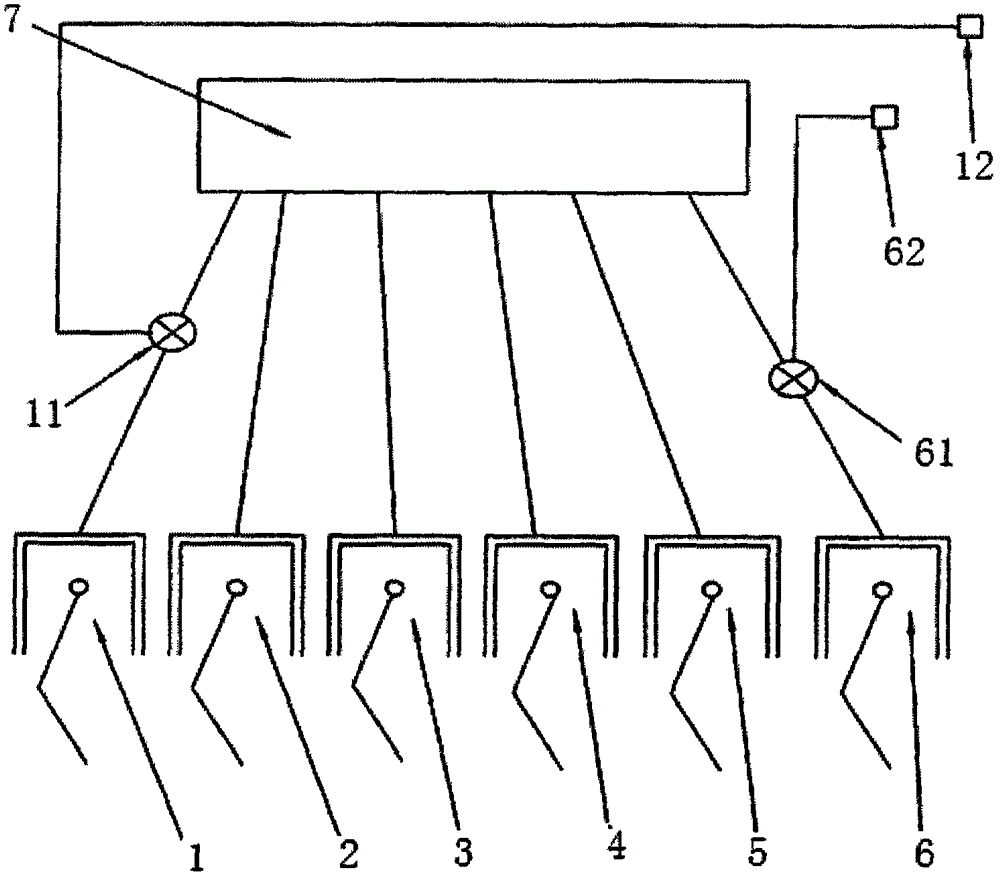

[0016] The fuel-saving device for a six-cylinder diesel automobile engine includes a common fuel injection pump 7 and six independent oil delivery pipelines connecting the fuel injection pump to the combustion chambers of each cylinder. 1 first cylinder, 2 second cylinder, 3 third cylinder, 4 fourth cylinder, 5 fifth cylinder, 6 sixth cylinder.

[0017] A first cylinder solenoid valve 11 is connected in series in the oil delivery pipeline from the fuel injection pump to the combustion chamber of the first cylinder 1, and the solenoid valve is controlled by a first cylinder solenoid valve switch 12 arranged in the cab. Similarly, a solenoid valve 61 of the sixth cylinder is connected in series in the oil delivery pipeline from the fuel injection pump to the combustion chamber of the sixth cylinder 6, and the solenoid valve is controlled by the solenoid valve switch 62 of the sixth cylinder arranged in the cab.

[0018] When the car is running at high speed, it can be switched a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com