Loading mechanism with multi-station function

A loading mechanism and multi-functional technology, applied in the direction of workbench, manufacturing tools, etc., can solve the problems of high labor intensity of operators, large shaking of manual operation, inaccurate docking, etc., to save docking time, improve production efficiency, fast and accurate The effect of docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] specific implementation plan

[0029] The present invention will be further explained in conjunction with the accompanying drawings.

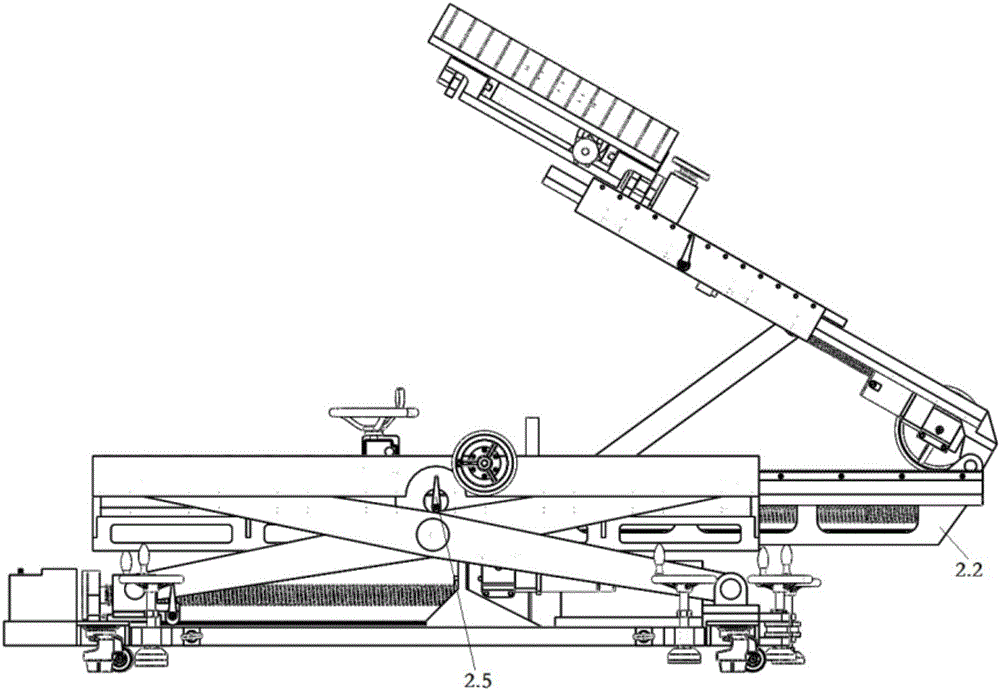

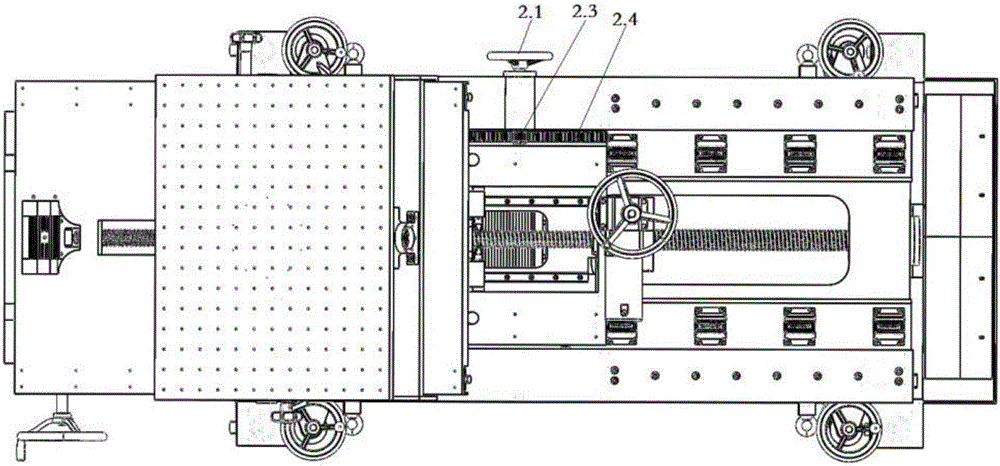

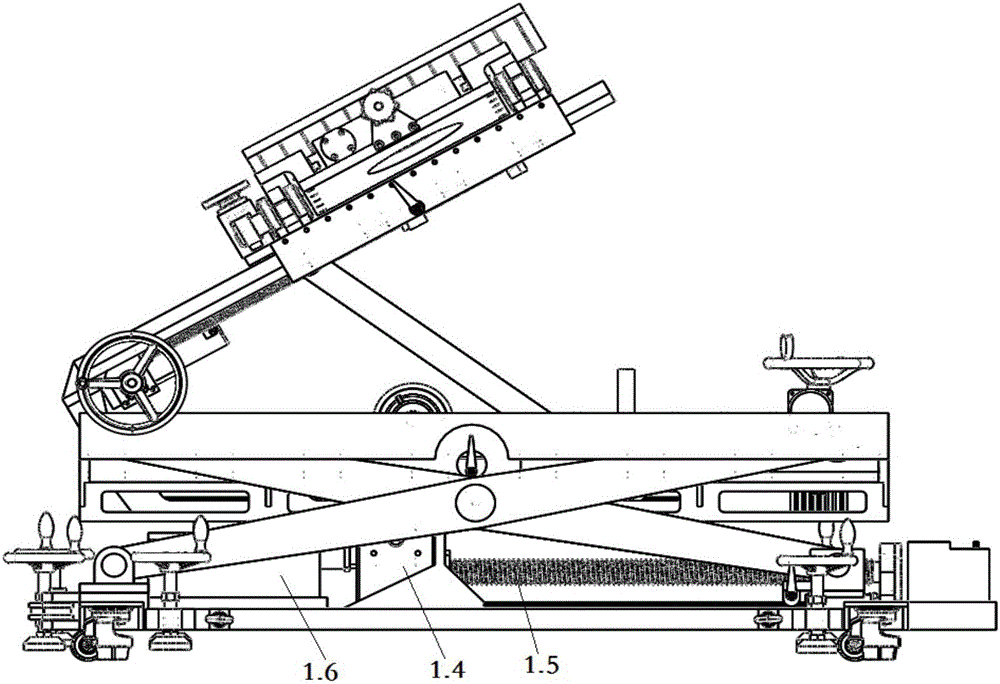

[0030] Such as Figure 1-7 As shown, the present invention provides a kind of all-round multifunctional electric satellite side panel installation loading robot, which includes,

[0031] The lifting mechanism is arranged on a lifting platform 8, and is used to drive the lifting platform 8 and the load on the lifting platform 8 to move in the vertical direction;

[0032] The telescopic mechanism is arranged on the lifting platform 8, and is used to drive the lifting platform 8 and the load on the lifting platform 8 to move in the horizontal direction;

[0033] The first moving mechanism is arranged on a pallet 9 and is used to drive the pallet 9 to move in the vertical direction;

[0034] The first turning platform is arranged on a swinging platform 10, and is used to drive the swinging platform 10 to swing along a predetermined track;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com