Singe-stage double-suction split case pump with good sealing performance

A sealing performance, single-stage double-suction technology, applied in the components, pumps, pump components of the pumping device for elastic fluids, etc., can solve the problems of easy mechanical fatigue, falling off of caulking screws, shortening of bearing life, etc. Achieve the effect of improving anti-cavitation performance, preventing falling off and reducing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in detail below with reference to the accompanying drawings. The description in this section is only exemplary and explanatory and should not have any limitation on the scope of protection of the present invention. .

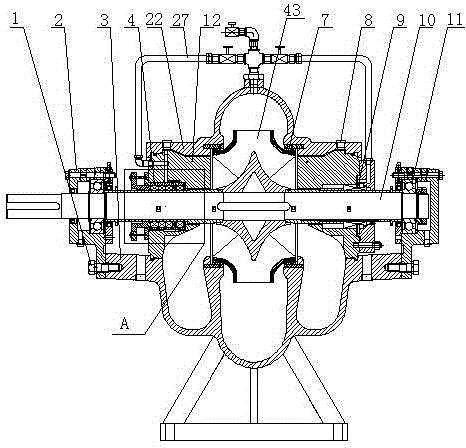

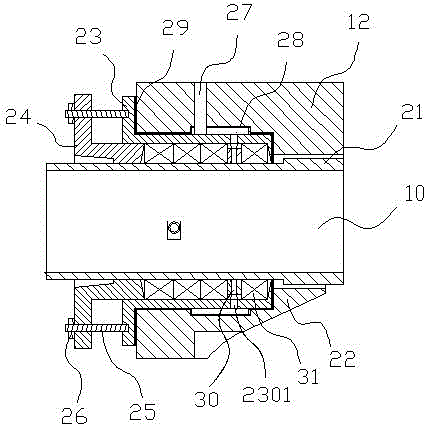

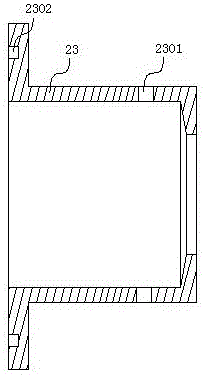

[0038] Such as Figure 1-Figure 6 As shown, the structure of the present invention is: a single-stage double-suction split pump with good sealing performance, which includes a front bearing seat 2, a rear bearing seat 11 and a pump shaft 10 passing through them. A shaft sleeve 21 is sleeved on the shaft 10, and an impeller 43 and a pump body 3 matched with the impeller 43 are sleeved in the middle of the pump shaft 10, and the pump body 3 is connected to the front bearing seat 2 and the rear through the fastener 1 The bearing housing 11 is connected, a sealing member 7 is provided between the pump body 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com