Coal leveling equipment

A technology for flat coal and equipment, applied in the field of flat coal equipment, can solve the problems of low work efficiency, affect production efficiency, low quality of flat coal, etc., and achieve the effects of stable operation, improved production efficiency, and improved quality of flat coal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

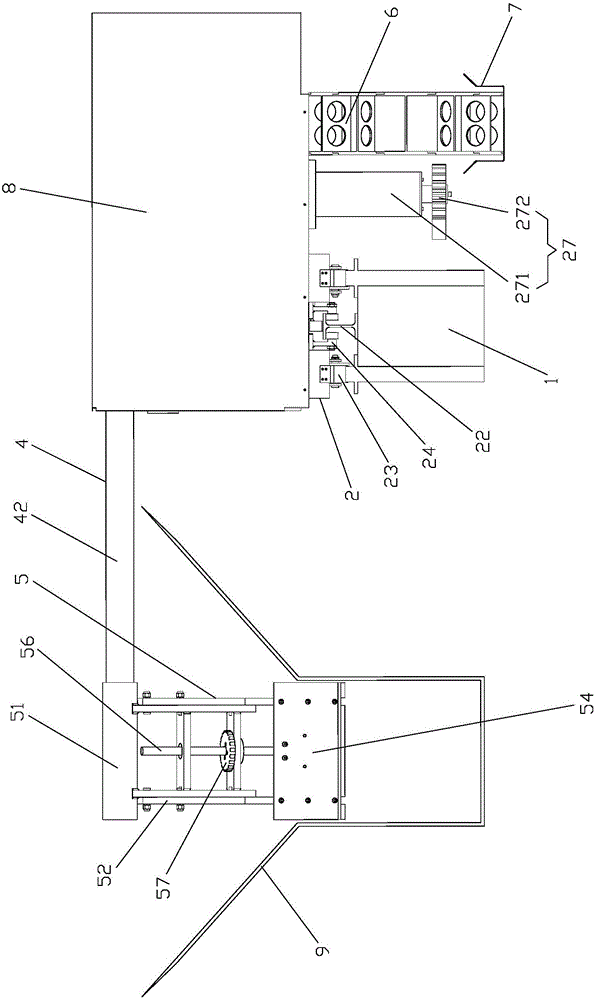

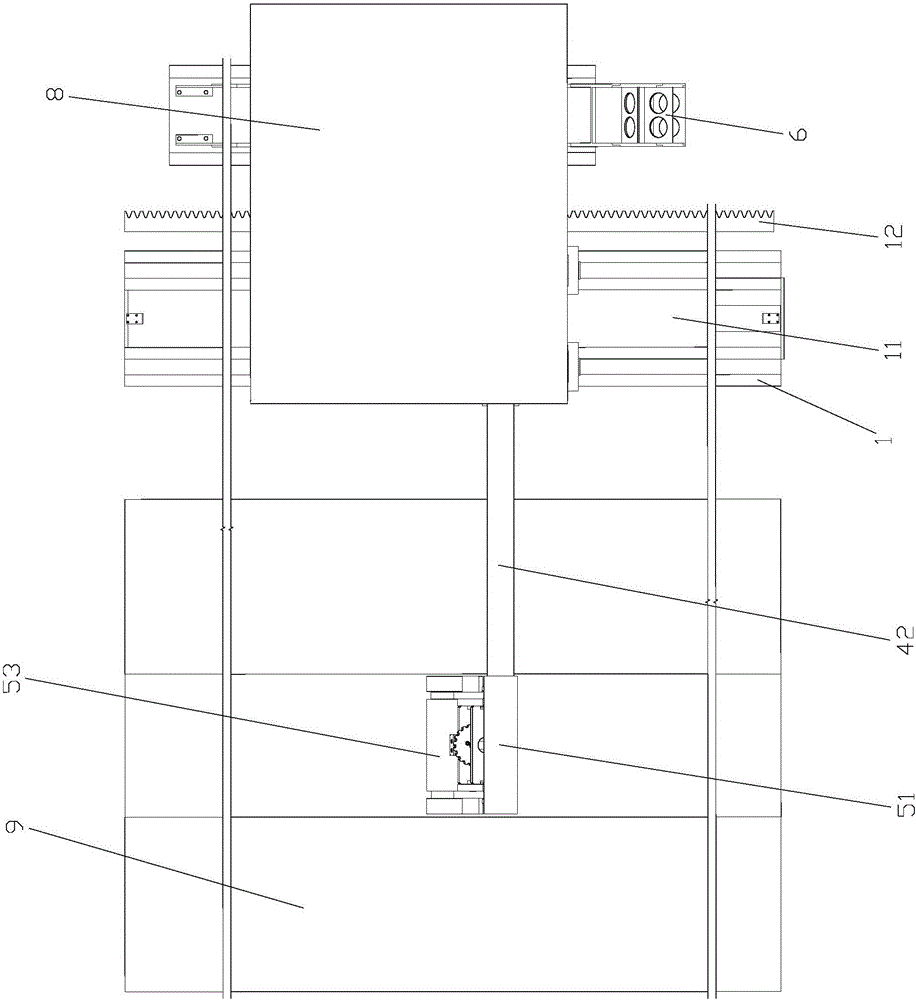

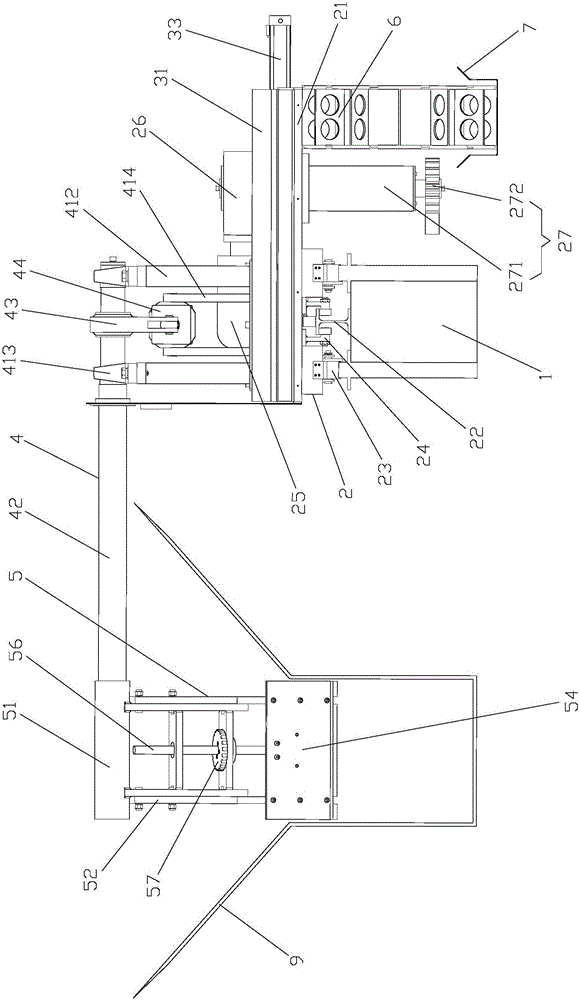

[0030] like Figures 1 to 8The coal leveling equipment of the present invention includes an anti-overturning track 1, a traveling mechanism 2, a flat coal plate telescopic mechanism 3, a turning mechanism 4, a leveling and compacting mechanism 5, an electrical cable drag chain 6, a drag chain box 7, a protection Hood 8 and electronic control system.

[0031] The anti-overturning rail 1 is in the shape of a long strip as a whole, and a rail groove 11 is formed along the length direction from the middle of the top surface. The lower side of the outer wall is symmetrically provided with a rack 12 along the length direction. In this embodiment, the rack 12 is 15m long; The anti-overturning rail 1 is made of I-beam, which has good bearing effect and strong anti-overturning ability in the lateral direction, and is suitable as the bearing guide rail of the anti-overturning mechanism.

[0032] The traveling mechanism 2 is slidably installed on the anti-overturning track 1. In this em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com