Automatic cargo picking system and automatic cargo picking method

A cargo and automatic technology, applied in the field of logistics and warehousing, can solve the problems of high labor intensity and low efficiency, and achieve the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to enable those skilled in the art to better understand the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0042] Firstly, the meanings of some terms involved in the embodiments of the present invention will be described below.

[0043] The container for containing the ordered goods is a container used to accommodate the ordered goods, which is also referred to as a material box for short in the following text.

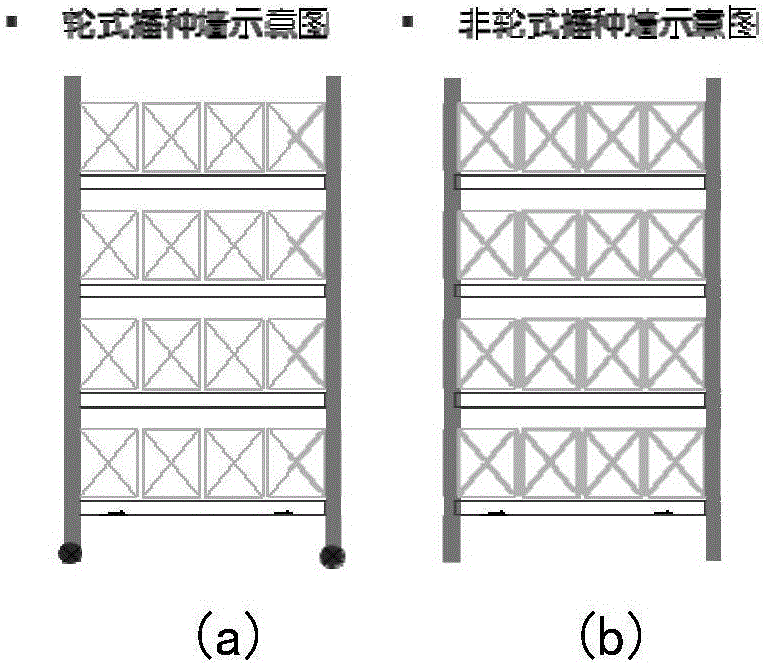

[0044] Planting walls, shelves for placing order goods holding containers.

[0045] The mobile planting wall refers to the mobile shelf, which is used to place the container for the order goods.

[0046] The wheeled mobile sowing wall refers to the installation of casters with stop devices at the bottom of the supporting legs of the sowing wall. A stop is a type of brake that, when activated, prevents unwanted movement of the moving planting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com