Device for continuously processing paperboard

A cardboard and moving board technology, applied in the field of cardboard processing, can solve the problems of inconvenience, low precision, and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other; the present invention will be described in detail below with reference to the accompanying drawings and in combination with the embodiments.

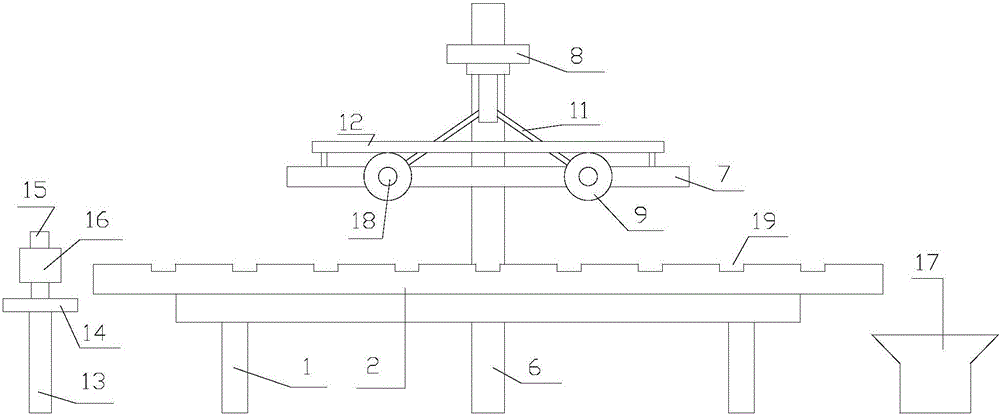

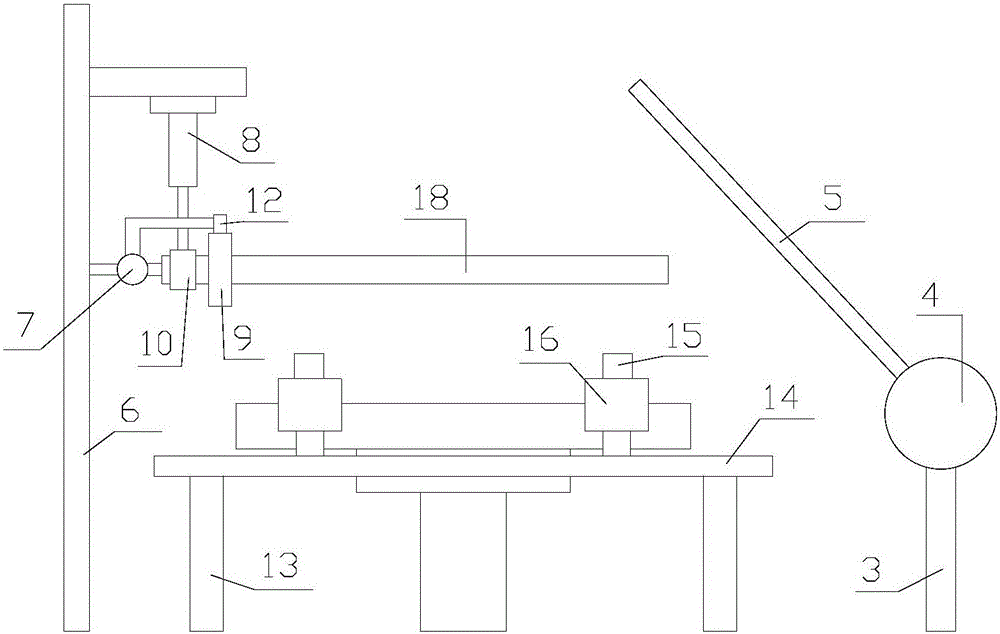

[0030] refer to figure 1 , 2 :

[0031] A device for continuous cardboard processing proposed by the present invention includes a base 1 , a moving plate 2 , a driving mechanism, a cutting mechanism, an auxiliary mechanism, a positioning mechanism, and a collecting box 17 .

[0032] The base 1 is provided with guide rails.

[0033] The moving plate 2 is movably installed on the guide rail; the upper surface of the moving plate 2 is provided with a plurality of receiving grooves 19, and the plurality of receiving grooves 19 are evenly distributed along the length direction of the guide rail. Avoid damaging the moving plate 2 surface.

[0034] The driving mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com