Chemical industry water energy-saving recycling device

A water and chemical technology, applied in the chemical industry, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of difficult popularization and application, large cooling water consumption, high energy consumption, and achieve easy popularization, improve production efficiency, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

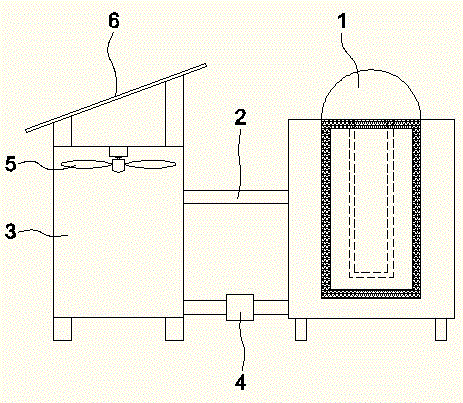

[0012] Such as figure 1 As shown, an energy-saving recycling device for chemical water of the present invention includes a reactor 1, the reactor 1 is connected to the cooling water tank 3 through the water outlet pipe 2, and the cooling water tank 3 is connected to the reactor 1 through the water pump 4, so The cooling water tank 1 is provided with a cooling fan 5 , and the cooling fan 5 and the water pump 4 are powered by a photovoltaic power supply system 6 installed on the top of the cooling water tank 1 .

[0013] The photovoltaic power supply system 6 includes a solar cell, an intelligent charge controller, an energy storage battery and an inverter, the intelligent charge controller is electrically connected to the solar cell and the energy storage battery, and the energy storage battery is electrically connected to the inverter The inverter is electrically connected to the cooling fan 5 and the water pump 4.

[0014] Compared with the prior art, the beneficial effects ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com