Vortex flow transducer evaluation method based on fractal information dimensions

An eddy current sensor and information dimension technology, applied in scientific instruments, instruments, analytical materials, etc., can solve the problems of decreased sensor sensitivity and high probability of missing detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

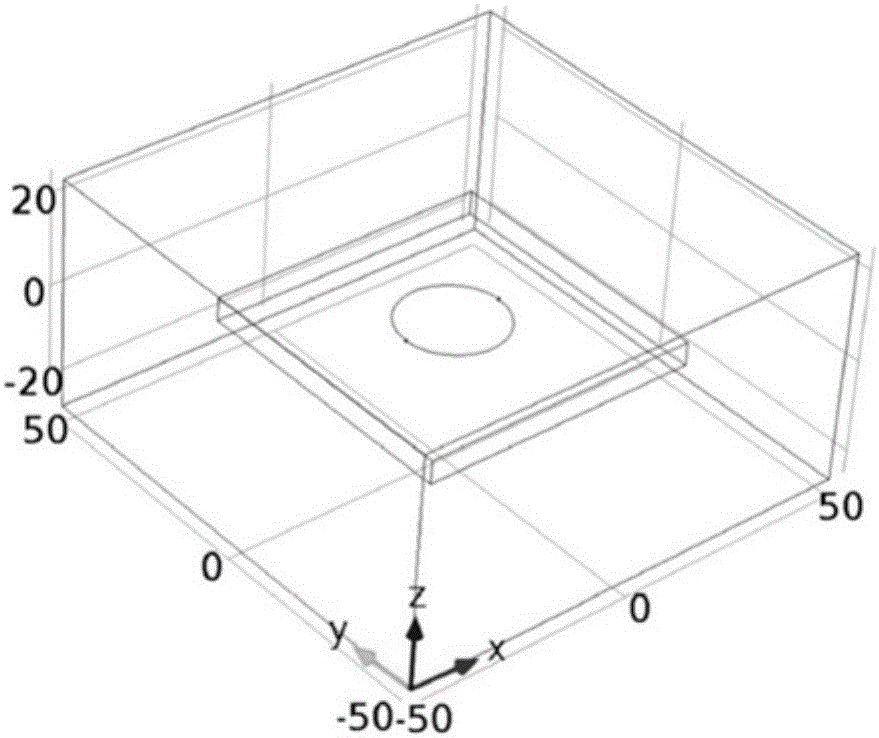

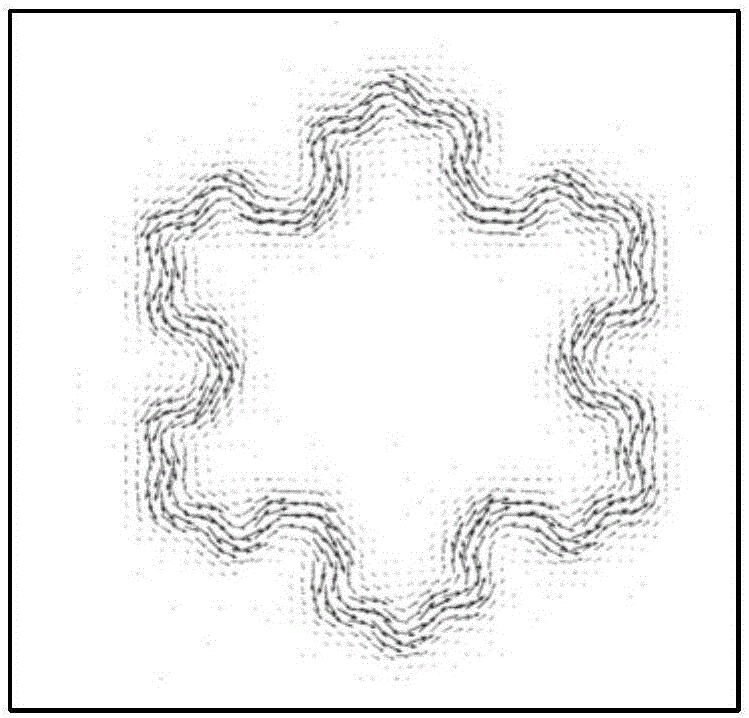

[0035] figure 1 Shown is the establishment of the simulation model. Under the same simulation conditions, different types of eddy current sensors induce different eddy current distributions. Such as figure 2 and image 3 Respectively, the eddy current distribution induced by the circular excitation coil and the third-order Koch fractal excitation coil of the same overall size. Since the crack detection ability of the eddy current sensor depends on the interaction strength between the crack and the eddy current, and this strength depends on the relationship between the direction of the eddy current and the crack direction, that is, the closer the included angle is to 90 degrees, the better the detection ability. powerful. When the crack size is smaller than the overall size of the excitation curve of the sensor, the strength of its interaction with the eddy current will decrease as the crack length decreases. Compared figure 2 and image 3 ,As can be seen, image 3 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com