Optical fiber Fabry-Perot electric field sensor for electrostatic field measurement

An electric field sensor and electrostatic field technology, applied in the field of sensors, can solve problems such as electric field distortion and affecting test results, and achieve the effect of improving dynamic range and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

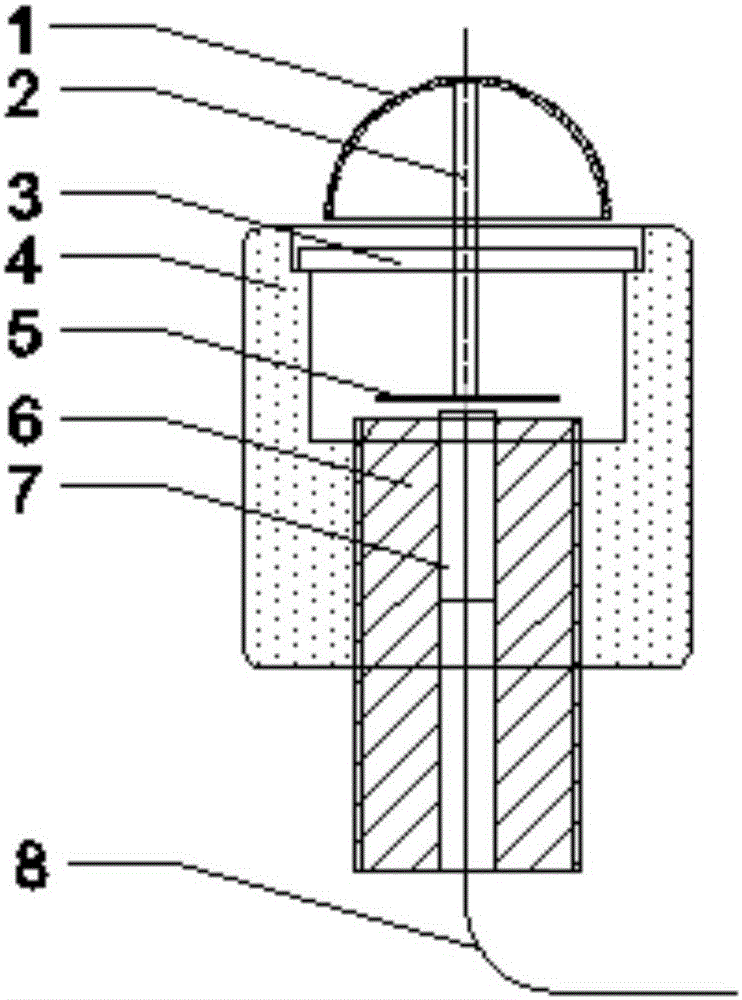

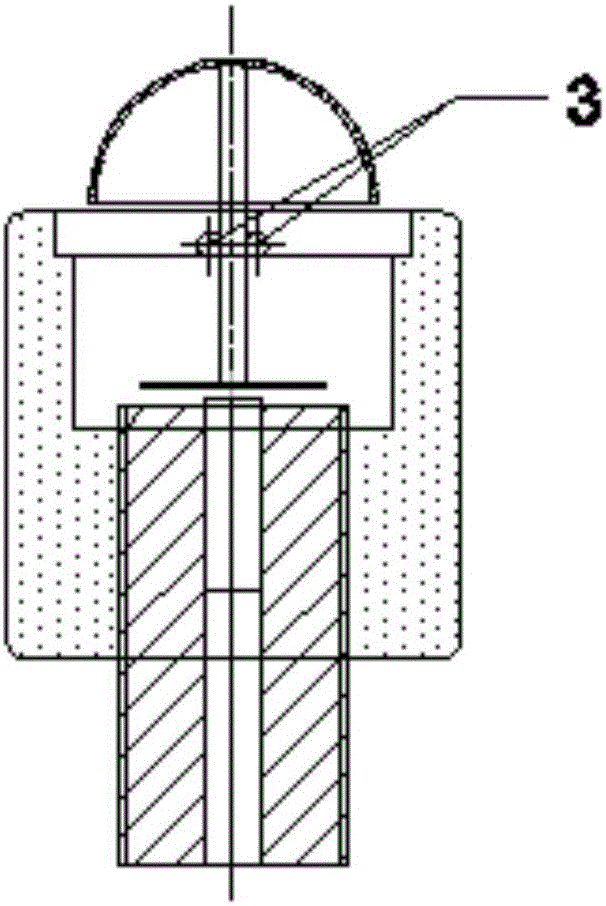

[0014] Specific implementation mode one: the following combination figure 1 with figure 2 Describe this embodiment, the optical fiber Fabry-Perot electric field sensor for electrostatic field measurement described in this embodiment, the electric field sensor includes a hollow hemisphere 1, a quartz column 2, two quartz rods 3, an insulating outer wall 4, and a quartz sheet 5 , trimmer 6 and fiber collimator 7;

[0015] Two quartz rods 3 are placed horizontally and parallel to each other. Two quartz rods 3 are welded vertically in the middle of the quartz column 2. The upper end of the quartz column 2 is glued with the hollow hemisphere 1, and the upper end of the quartz column 2 is located in the cavity of the hollow hemisphere 1. Inside, the lower end of the quartz column 2 is glued with a quartz thin slice 5, and the quartz thin slice 5 is placed horizontally. An insulating outer wall 4 is provided on the outside of the upper half of the quartz rod 3, the quartz sheet 5 ...

specific Embodiment approach 2

[0018] Embodiment 2: In this embodiment, Embodiment 1 is further explained. The hollow hemisphere 1 is made of polypropylene material, and its outer radius is 12.7 mm, and its inner radius is 11.5 mm.

specific Embodiment approach 3

[0019] Embodiment 3: In this embodiment, Embodiment 1 is further described. The radius of the section of the quartz column 2 is 1.05 mm, and the length is 30 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer radius | aaaaa | aaaaa |

| Inner radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com