A ring-cloth double-cone friction type stepless automatic transmission device

A technology of automatic transmission and double-cone truss, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve problems such as low transmission efficiency, complex structure of internal parts, difficult fault diagnosis of CVT, etc., to ensure stable transmission , The effect of stable stepless speed change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

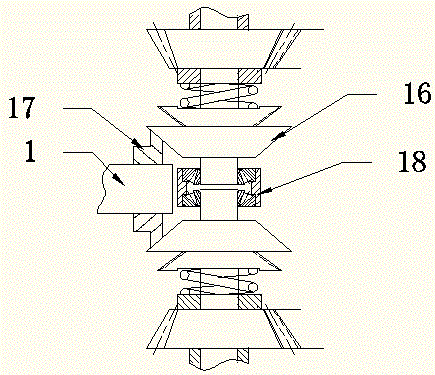

[0026] The invention specifically relates to a ring-cloth double-cone friction type stepless automatic transmission device utilizing friction transmission, as shown in the attached figure 1 As shown, it specifically includes the box body 6, and the input shaft 1, the output shaft 8 arranged on the box body 6, and the parts arranged on the two shafts inside the box body 6, the input shaft 1 and the output shaft 8 pass through the cylindrical roller The sub-bearing 7 is installed on the transmission case 6, and the bearing end cover 2 is used for axial positioning of the bearing, and the case 6 is dust-proof sealed. The input shaft 1 and the output shaft 8 are coaxially installed to further ensure the entire device during torque transmission. Stability; wherein one end of the input shaft 1 is provided with a frustum-shaped friction disc 17, and the friction disc 17 slides along the input shaft 1 under the action of the hydraulic pusher 3, and one end of the output shaft 8 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com