Inner-beam suspended air train track turnout

A suspended, empty column technology, applied in the direction of rails, roads, moving rail parts, etc., can solve the problems of difficult installation and maintenance, high driving energy consumption, large mechanism, etc., and achieve the effect of stable driving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

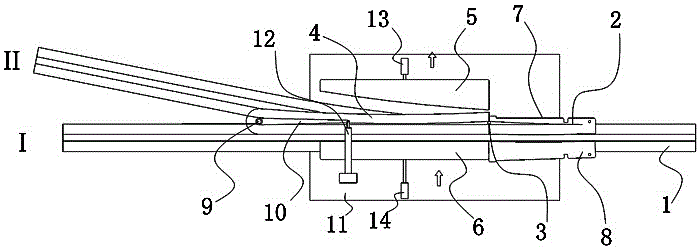

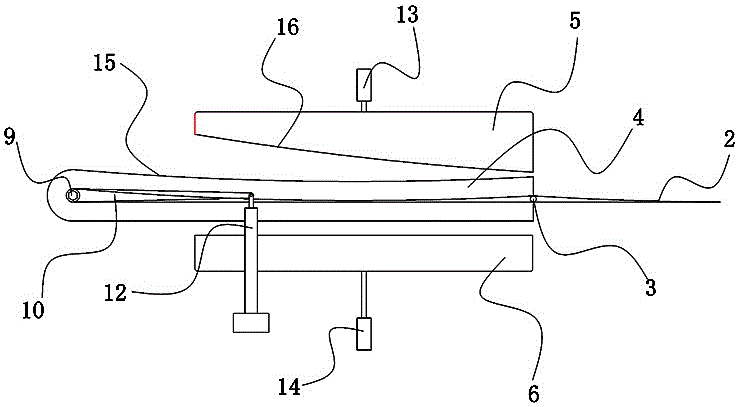

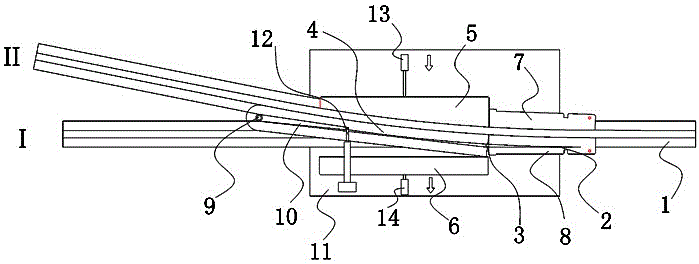

[0016] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

[0017] Such as Figure 1 ~ Figure 4 As shown, a beam-in-suspension type empty row track turnout includes two or more cross-track beams 1 that are not disconnected, and it also includes main functional components and auxiliary functional components, and the auxiliary functional components are capable of rotating or moving The auxiliary function parts include the avoidance / compensation plate A5, the avoidance / compensation plate B6, the correction plate A7 and the correction plate B8, and the avoidance / compensation plate A5 and the avoidance / compensation plate B6 are respectively slidably installed on the supporting plate 11 to The avoidance swings into the space after the switch part 4 and the compensation switch part 4 are put out, the avoidance / compensation plate A5 is locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com