An insulating material for a solid-sealed pole, a solid-sealed pole for a circuit breaker, and a preparation method thereof

A technology of solid-sealed poles and circuit breakers, which is applied to high-voltage air circuit breakers, insulators, organic insulators, etc., can solve the problems of poor heat dissipation, low processing efficiency, and large difference in expansion coefficient, etc., to improve surface quality and improve production Efficiency, the effect of reducing the temperature rise of the circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The insulating material for the solid-sealed pole of this embodiment is composed of the following components in weight percentage: nylon 55%, glass fiber 35%, additive 10%; nylon is PA66, glass fiber adopts boulder glass fiber, additive is anti-oxidant Aminopropyltriethoxysilane and polydimethylsiloxane, the weight ratio of antioxidant to polydimethylsiloxane is 1:1; the aspect ratio of glass fiber is 20, which has good tensile strength strength.

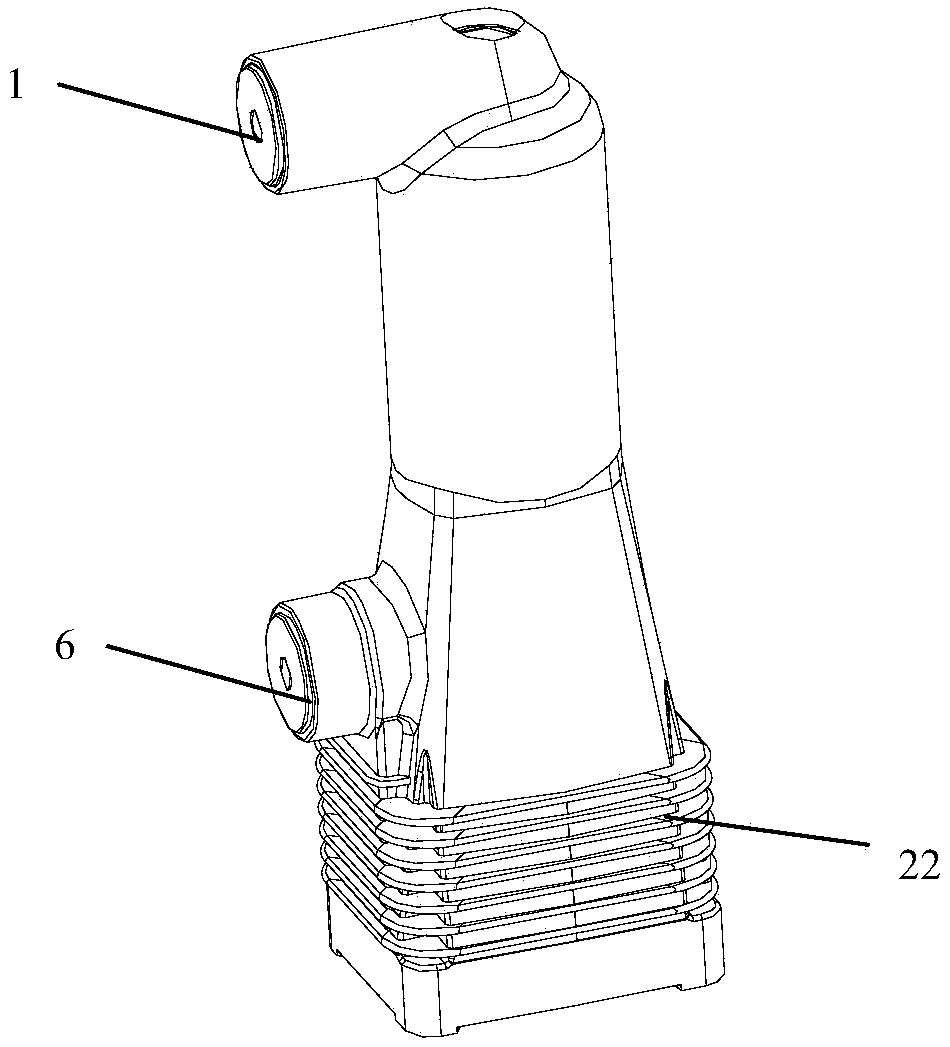

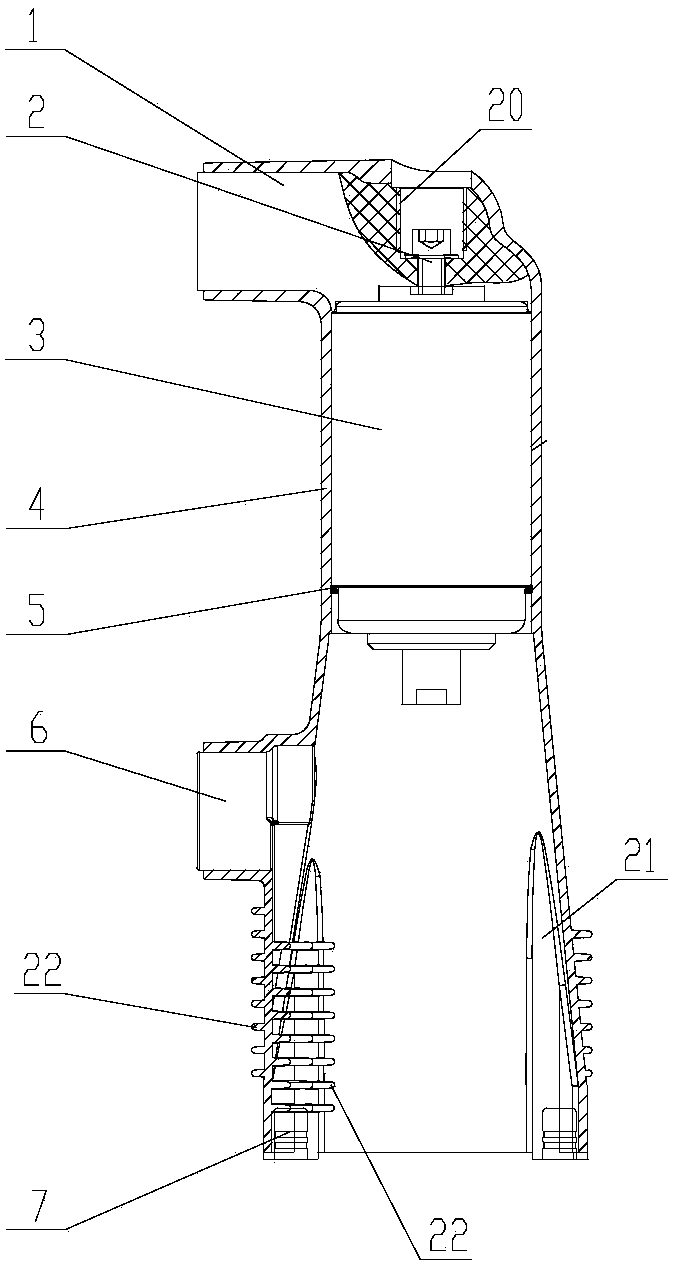

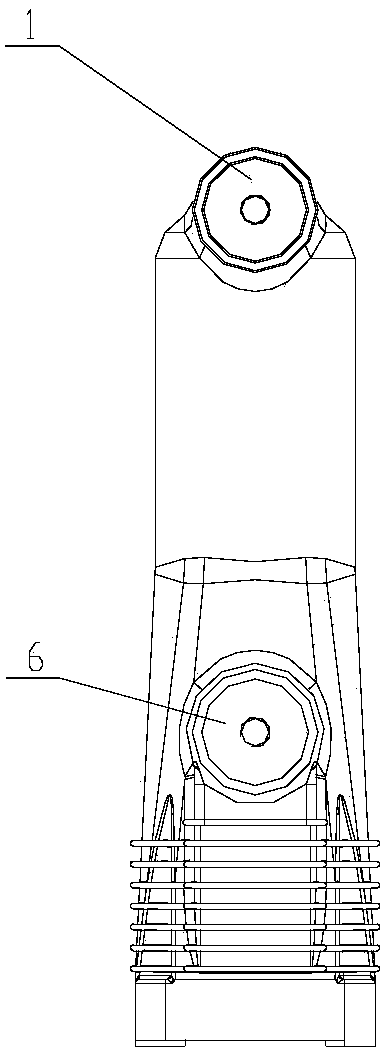

[0042] The solid-sealed pole for a circuit breaker in this embodiment includes an insulating case 4 and an upper conductor 1, a vacuum interrupter 3, a lower conductor 6, and an insert 7 arranged in the insulating case. The pole sealing post is made of insulating material.

[0043]The insulating shell seals the upper conductor, the vacuum interrupter, the lower conductor, and the insert as a whole. The insulating shell as a whole presents a shape below the upper circle, with uniform thickness and smooth transition at the con...

Embodiment 2

[0051] The insulating material for the solid-sealed pole of this embodiment is composed of the following components in weight percentage: 60% nylon, 30% glass fiber, and 10% additive; the nylon is PA66, the glass fiber is boulder glass fiber, and the additive is antioxidant Aminopropyltriethoxysilane and polydimethylsiloxane, the weight ratio of antioxidant to polydimethylsiloxane is 1:2; the aspect ratio of glass fiber is 40, which has good tensile strength strength.

[0052] The structure of the embedded pole for the circuit breaker of this embodiment is the same as that of Embodiment 1.

[0053] The preparation method of the circuit breaker embedded pole of the present embodiment comprises the following steps:

[0054] 1) First, fix the upper conductor and the vacuum interrupter through hexagon socket head screws, place it in the forming mold, thread the locking thread on the upper end of the upper conductor and the locking bolt on the inner wall of the forming mold, and p...

Embodiment 3

[0058] The insulating material for the solid-sealed pole of the present embodiment is made up of the following components by weight percentage: nylon 58%, glass fiber 30%, auxiliary agent 12%; Nylon is PA6, glass fiber adopts boulder glass fiber, auxiliary agent is antioxidant Aminopropyltriethoxysilane and polydimethylsiloxane, specifically using silicone master powder, the weight ratio of antioxidant to polydimethylsiloxane is 1:1.5; the aspect ratio of glass fiber is 30, with good tensile strength.

[0059] The structure of the embedded pole for the circuit breaker of this embodiment is the same as that of Embodiment 1.

[0060] The preparation method of the circuit breaker embedded pole of the present embodiment comprises the following steps:

[0061] 1) First, fix the upper conductor and the vacuum interrupter through hexagon socket head screws, place it in the forming mold, thread the locking thread on the upper end of the upper conductor and the locking bolt on the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com