Iron oxide pigment production equipment

A technology for iron oxide pigments and production equipment, which is applied in the direction of iron oxide, iron oxide/iron hydroxide, etc., and can solve problems such as energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

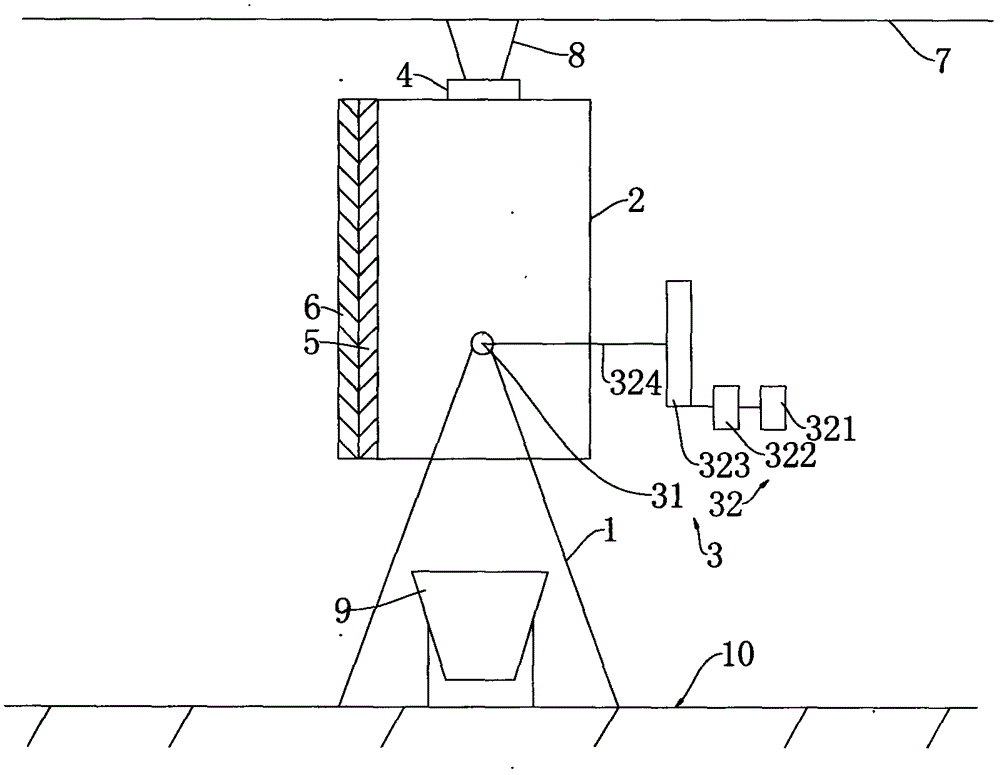

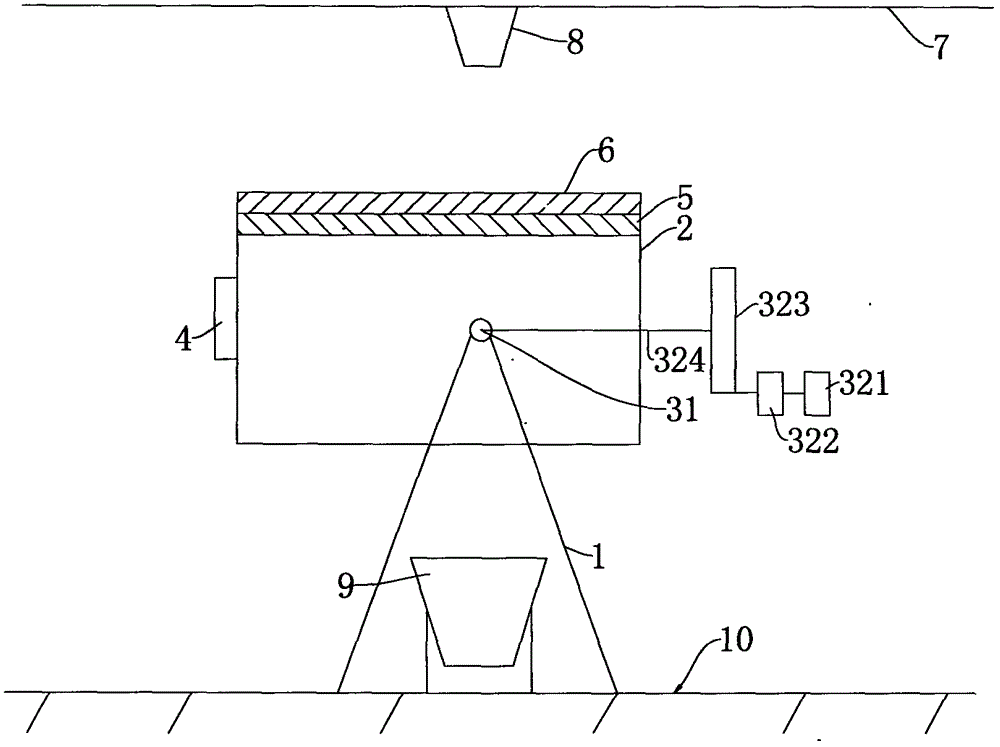

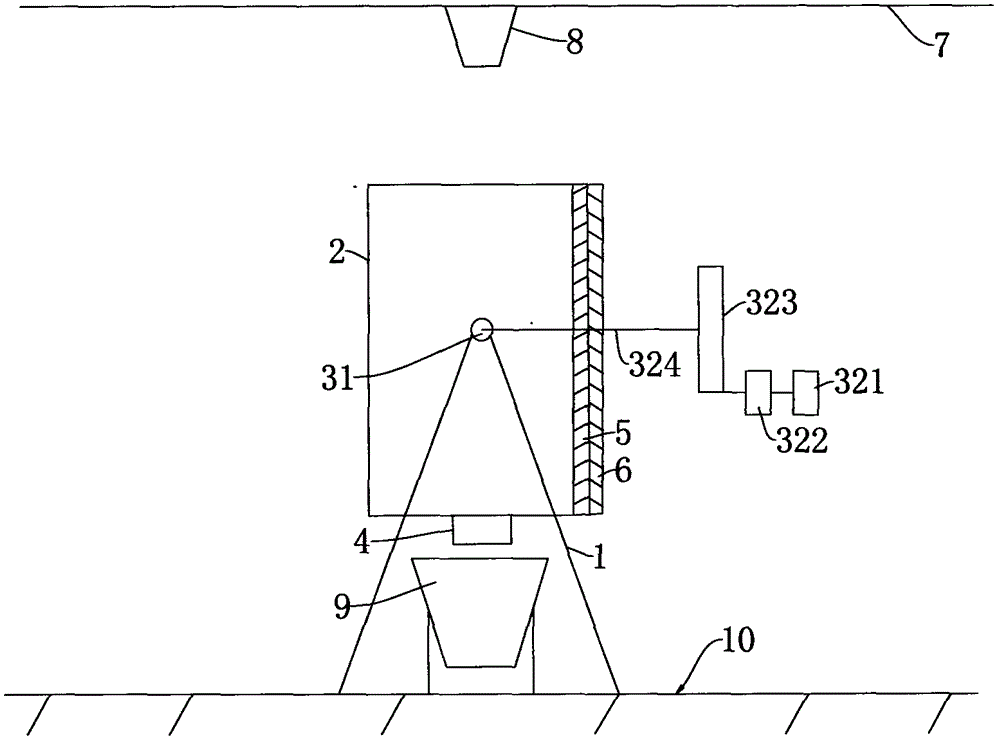

[0015] In order to understand the technical scheme of the present invention more intuitively and completely, the non-limiting feature descriptions are as follows in conjunction with the accompanying drawings of the present invention:

[0016] Such as Figure 1-Figure 4 As shown, the iron oxide pigment production device includes: a support 1, which is placed on the ground 10; a cylindrical drum 2, which is rotatably installed on the top of the support 1 by a rotating mechanism 3, and the top of the drum 2 A material inlet and outlet 4 is provided, a heater 5 is provided on one side of the drum 2, and an external insulator 6 is provided outside the heater 5; a feeding platform 7 is arranged above the drum 2, and an inlet and outlet are provided on the feeding platform 7. The feeding hopper 8 corresponding to the feeding port 4 ; the cooling mixer 9 , which is placed on the ground 10 and used for cooling the ferric oxide feed poured out from the drum 2 .

[0017] The rotating me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com