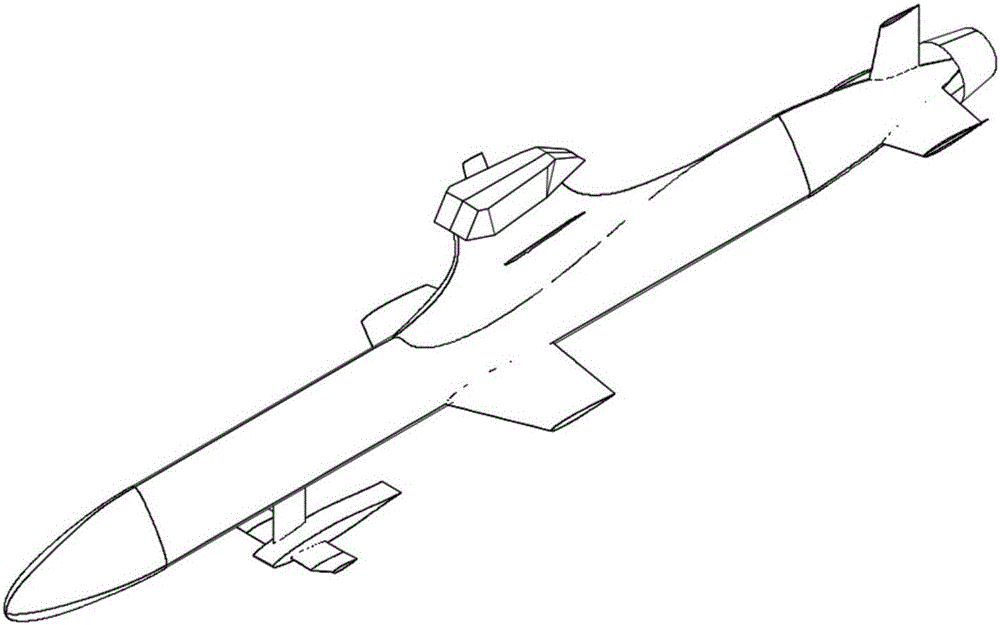

Triangular-section power draft-increase ballast-free semi-submersible conveying ship

A triangular, ballast water technology, applied in the direction of underwater ships, ships, motor vehicles, etc., can solve the problems of loss of control ability, reduced reliability, difficult to guarantee structural strength, etc., to reduce waves and slam loads, and reduce sway. and stall, facilitating material loading and unloading and personnel escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

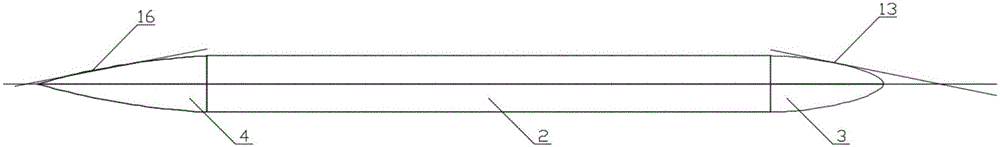

[0027] In conjunction with the accompanying drawings, the displacement main hull 1 of the present invention is in the form of a streamlined slender watertight single hull, the maximum width and height are 1 / 15 of the total length of the hull, and the aspect ratio is 12 to 18. The interior space is equipped with engine room, The cargo hold, oil-water tank and living compartment mainly include three parts: the parallel center body 2 of the middle section, the blunt bow 3 of the inflow section and the conical stern 4 of the outflow section. The excellent sailing performance of the semi-submerged state near the water surface is realized by inventing the three-part profile form. The parallel center body 2 is located in the midship of the main hull 1, the length is 2 / 3 of the length of the boat, the rear end is 1 / 5 of the length of the boat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com