Coupling sensor

A sensor and connection mechanism technology, applied in the direction of traction connectors, instruments, scientific instruments, etc., can solve problems that cannot be clearly determined

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

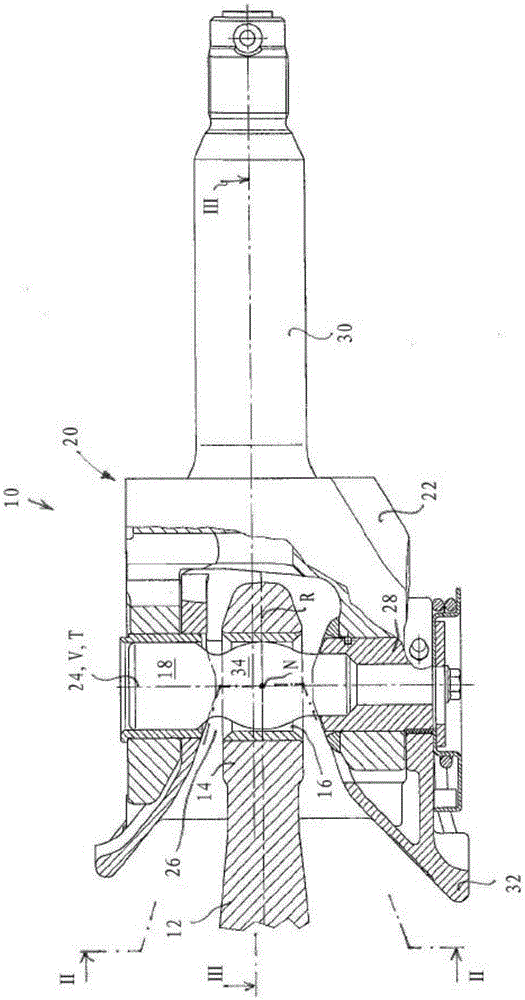

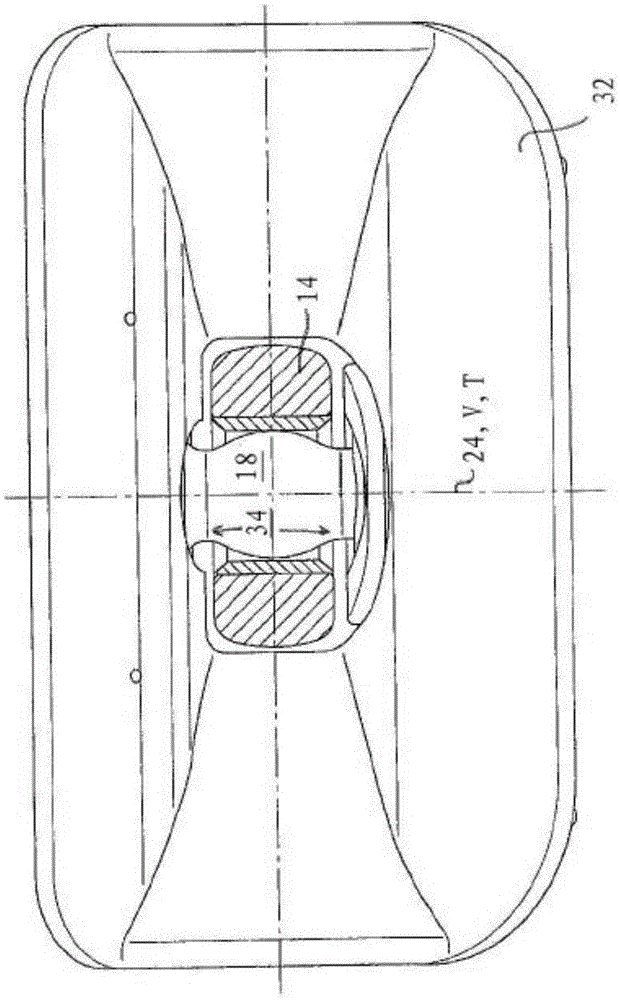

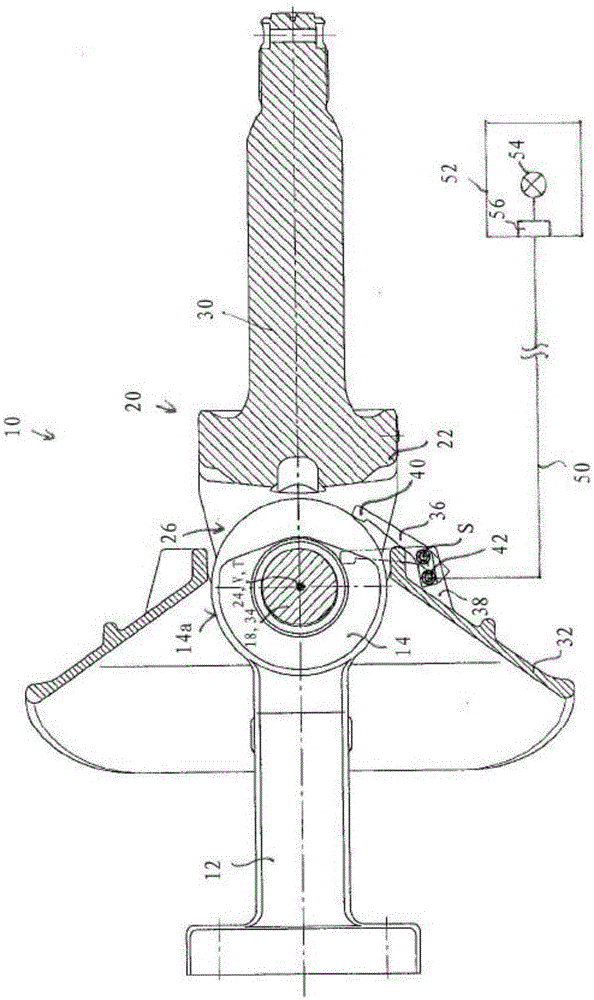

[0047] exist figure 1 In is a first embodiment of the coupling arrangement of the present invention, generally designated 10 . At the same time it is a bolted coupling. In a manner known per se, the coupling arrangement has a tow bar 12 , which is generally fixedly connected to a trailer (not shown in the figures), and a tow eye 14 is arranged at its longitudinal end remote from the vehicle. The circular hole 16 of the traction ring 14 is in figure 1 Passed by a coupling pin 18 in the view. The coupling pin 18 is thus in the coupling position.

[0048] The coupling pin 18 is an integral part of a cardan joint mechanism 20 which is generally fixedly connected to the tractor.

[0049] Universal joint mechanism 20 in figure 1 In the illustrated embodiment there is a coupling body 22, the coupling pin 18 being displaceably accommodated along an adjustment track V generally coincident with the longitudinal axis 24 of the coupling pin between an open position, not shown, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com