A digital and precise ink supply method for a printing machine

A printing machine and ink supply technology, which is applied to printing machines, general parts of printing machinery, printing, etc., can solve the problem that absolute accuracy and relative accuracy cannot be guaranteed, ink supply calculation, adjustment and control are difficult, and ink cannot be known Quantity and other issues to achieve the effect of shortening preparation time, weakening dependence on personal skills and experience, and reducing equipment maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the drawings.

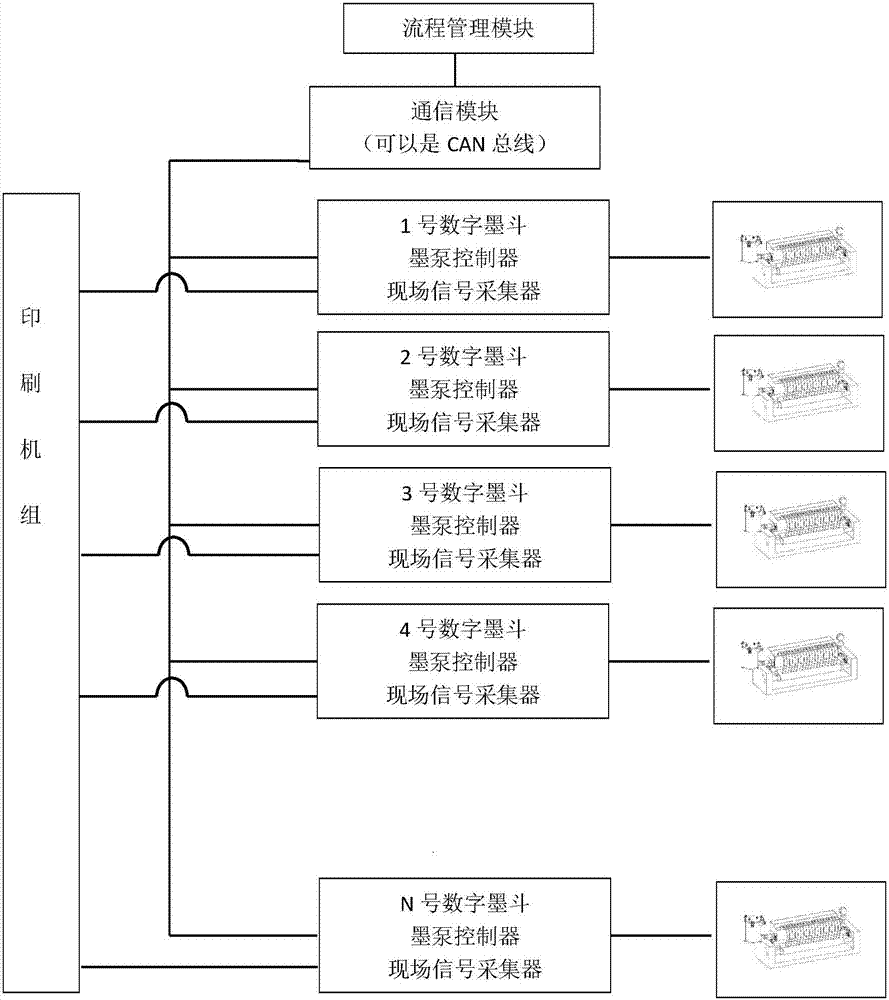

[0022] Such as figure 1 As shown, a method for digitizing and precise ink supply of a printing machine is realized by replacing the ink key on a traditional printing machine with a metered ink delivery unit. Each metering ink delivery unit directly delivers ink to the corresponding ink zone. Volume or mass is the basis of measurement, realizing the quantitative supply of ink for each ink zone.

[0023] The output volume and output capacity of the metered ink delivery unit for the medium can be calculated according to the shape and size of its structure, or its output can be quantitatively controlled, including metering plunger pumps, syringe pumps, and peristaltic pumps. Pumps, gear pumps, screw pumps.

[0024] The one or more metered ink delivery units are arranged in accordance with the printing format to replace the ink fountain of the traditional printing machine, and each metered i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com