Test-piece clamping pincers for CTOD testing

A test piece clamping and testing technology, applied in the direction of chucks, manipulators, manufacturing tools, etc., can solve the problem that the test piece cannot be seated at one time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

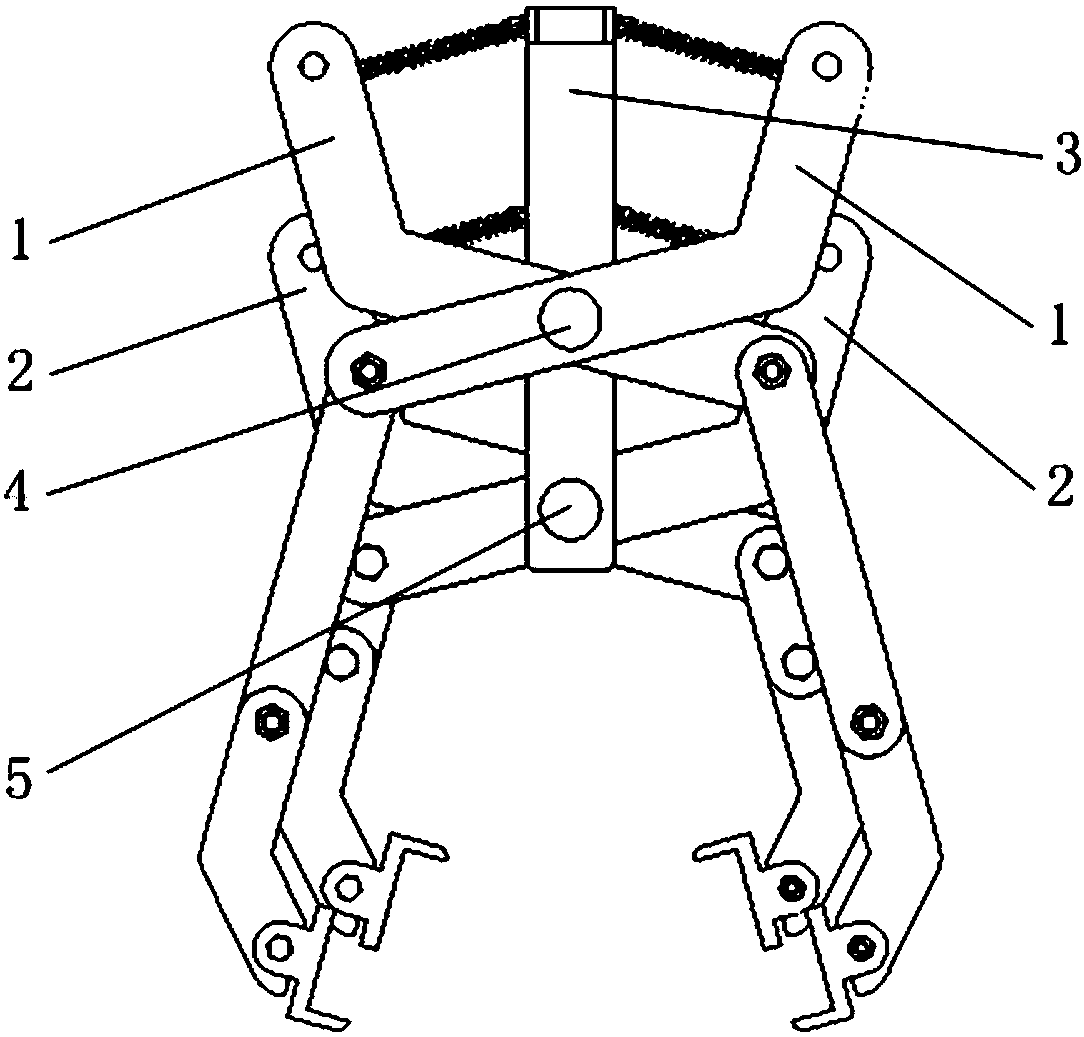

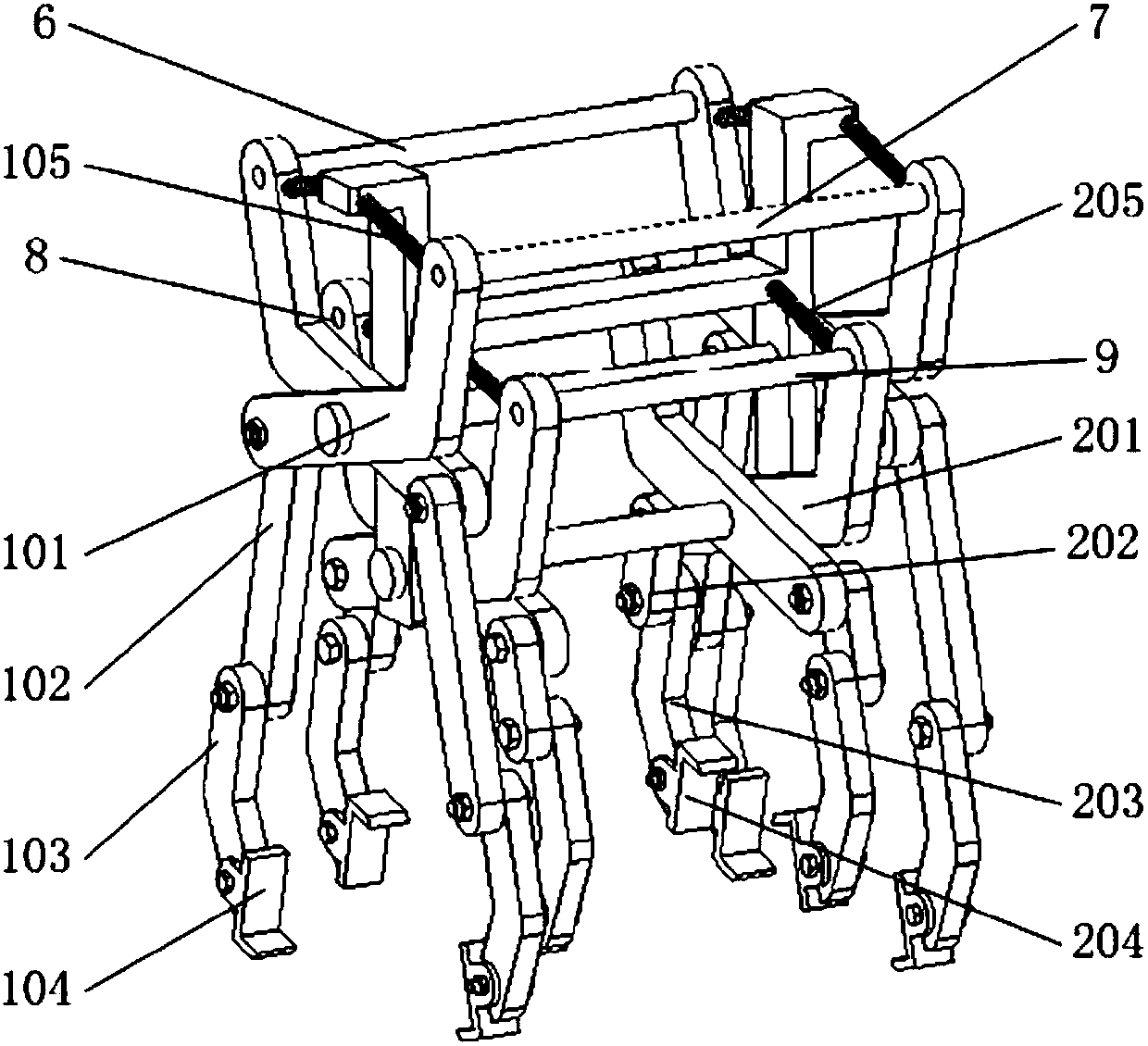

[0025] see Figure 1 to Figure 3 , shows the CTOD test specimen clamping pliers of the present invention, which is used to test the open displacement test of the crack tip of the welded joint. During the test, the tester is used to clamp the specimen, which can ensure that the specimen can be safely and conveniently , Clamping, moving and positioning smoothly.

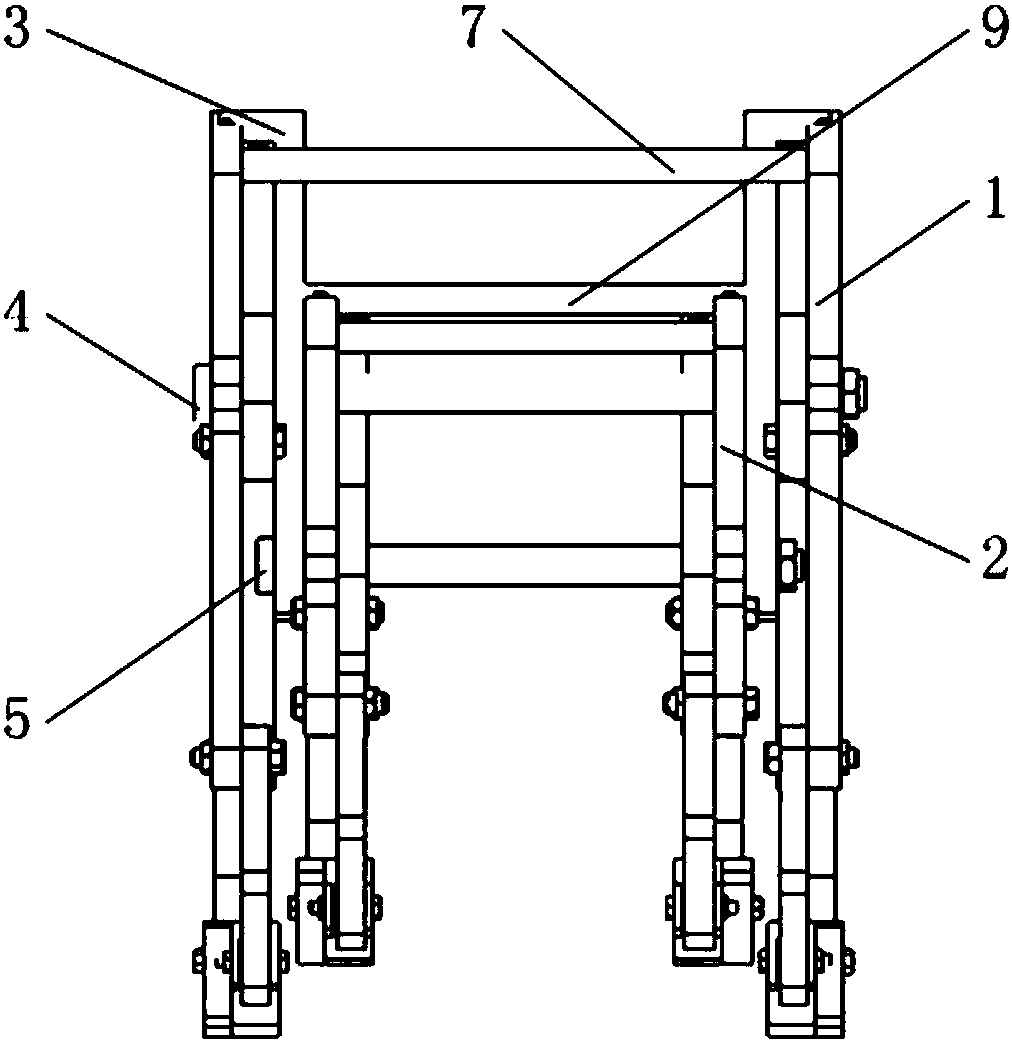

[0026] Described CTOD test specimen clamping clamp comprises support frame 3, two sets of main clamps and two sets of auxiliary clamps, see image 3 , the support frame 3 is an I-shaped member, and the two sides are oppositely arranged connecting rods, and the two connecting rods are connected through an intermediate rod, and the connecting rods are relatively arranged in parallel, and each set of main tongs is composed of two main tong assemblies 1, Each set of auxiliary tongs is composed of two auxiliary tongs assemblies 2. The main tongs component 1 includes a pliers handle 101, an adjustment rod 102, a large turn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com