Adhesion clamp for smoke baffle

A smoke baffle and bonding technology, which is applied in the direction of connecting components, manufacturing tools, workpiece clamping devices, etc., can solve the problems of low bonding efficiency, increased processing costs, and difficulty in ensuring the accuracy of the bonding size and position, and achieves the goal of bonding High bonding efficiency and precision, fewer bonding processes, convenient and reliable bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

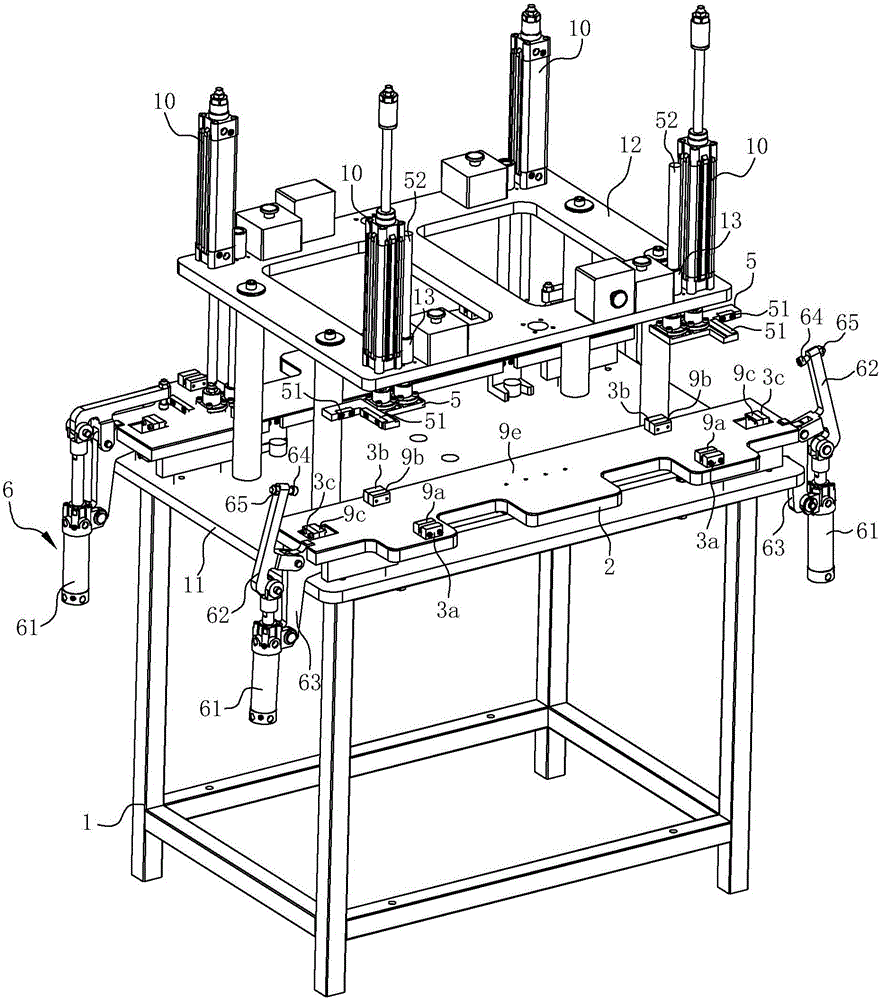

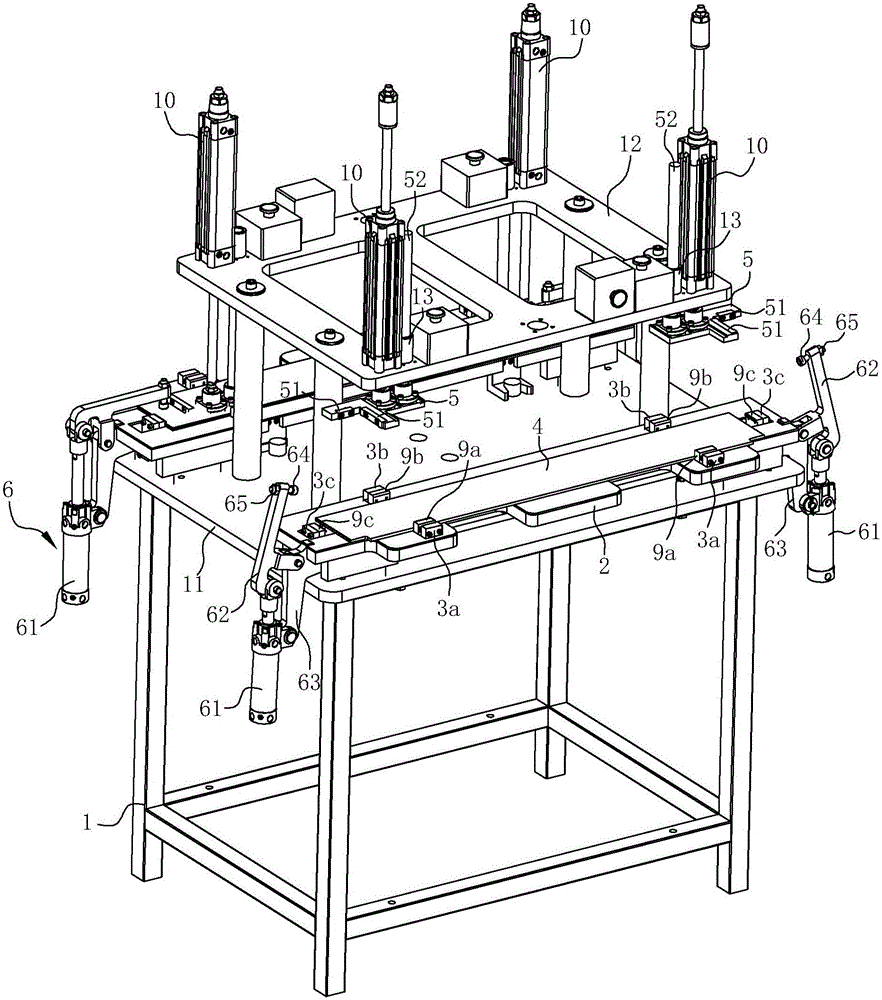

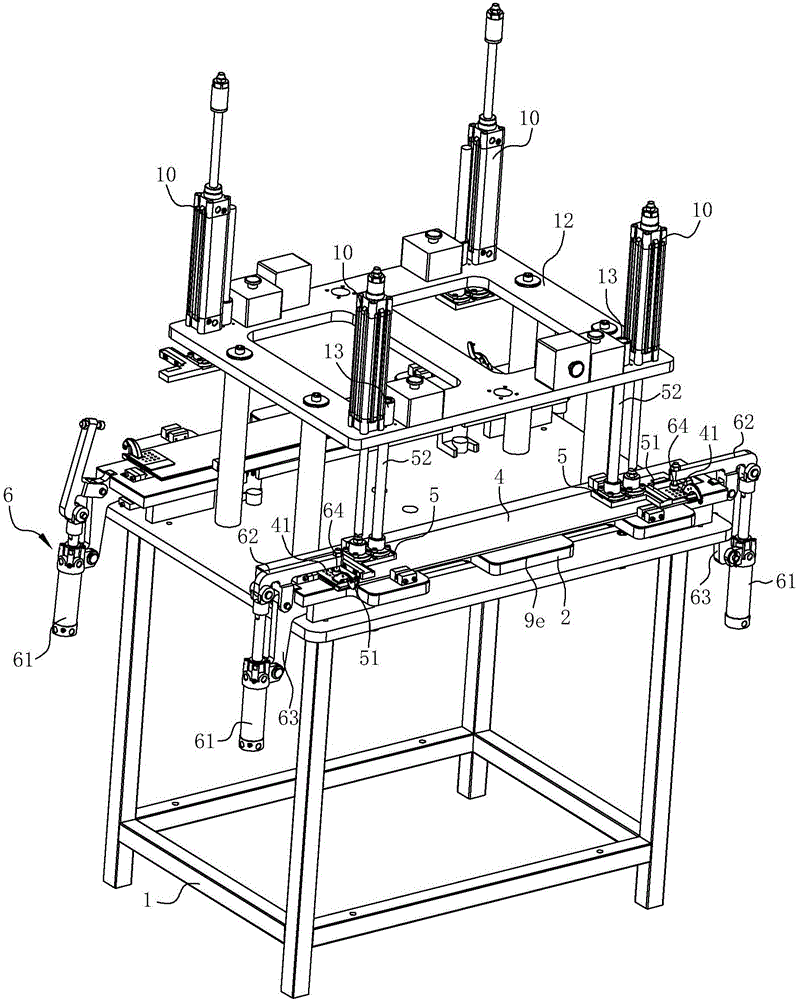

[0028] Such as Figure 1-9 Shown is a preferred embodiment of the present invention.

[0029] A smoke baffle bonding fixture for bonding a rotating shaft component 41 to a smoke baffle 4, comprising a frame body 1 with a table top 11 and an upper mounting plate 12 above the table 11, between the table 11 and the upper mounting plate 12 Supported by columns. At least one set of bonding structures is provided on the frame body 1 , and there are two sets of bonding structures in this embodiment, which are respectively arranged on the front and rear sides of the frame body 1 .

[0030] Each bonding structure includes:

[0031] The shelf 2 for the smoke baffle 4 is installed on the table 11, there is a distance between the shelf 2 and the table 11, and the upper end surface of the shelf 2 is fixed with a lower flexible pad 9e which is in direct ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com