reaction tower

A technology of reaction tower and tower body, which is applied in the field of large vertical reaction vessels, can solve the problems of high price of tower body materials, tower body material consumption, tower body prone to instability, etc., to achieve manufacturing cost saving, stable structure, Avoid the effect of local instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention are described in detail below:

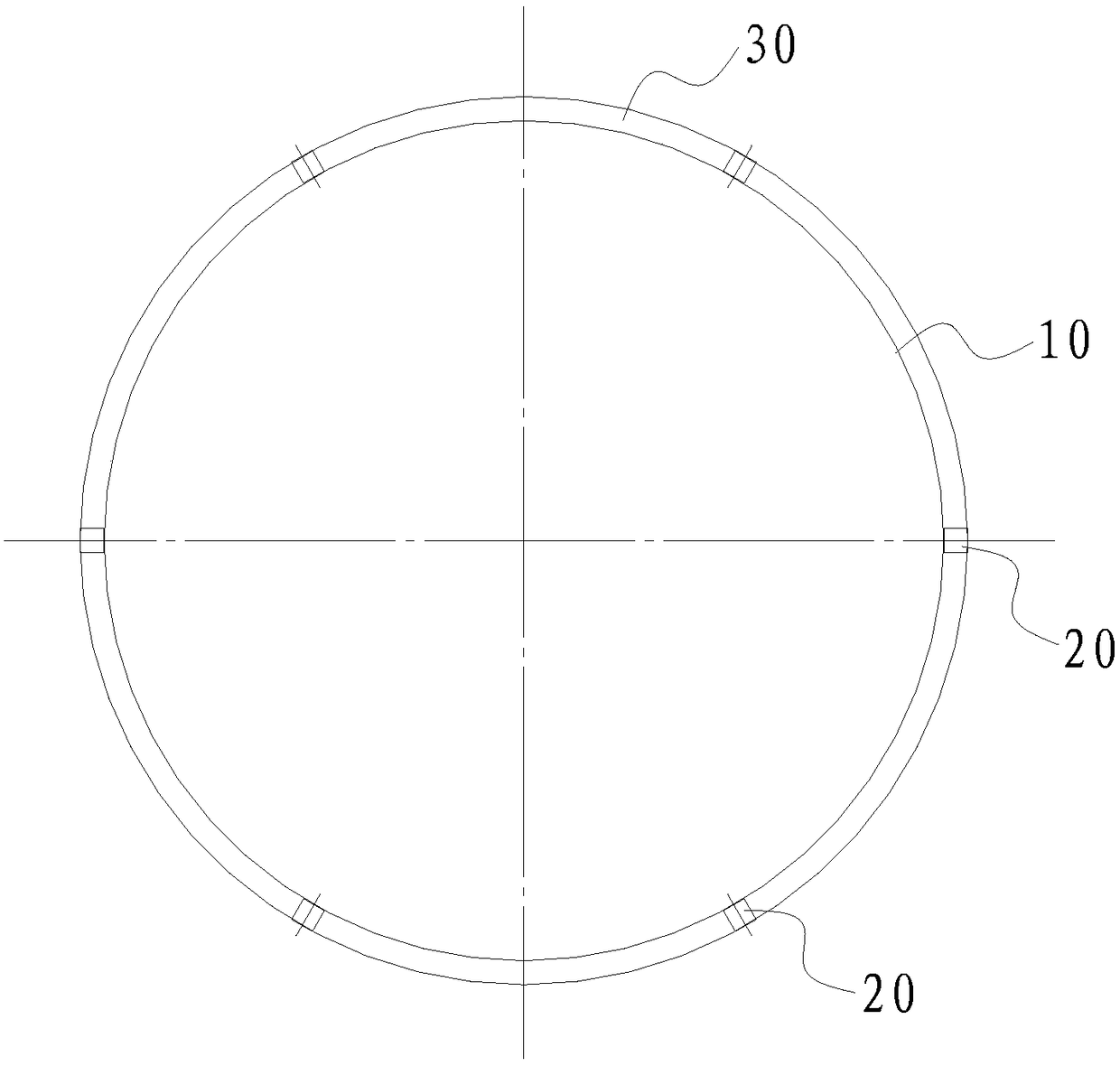

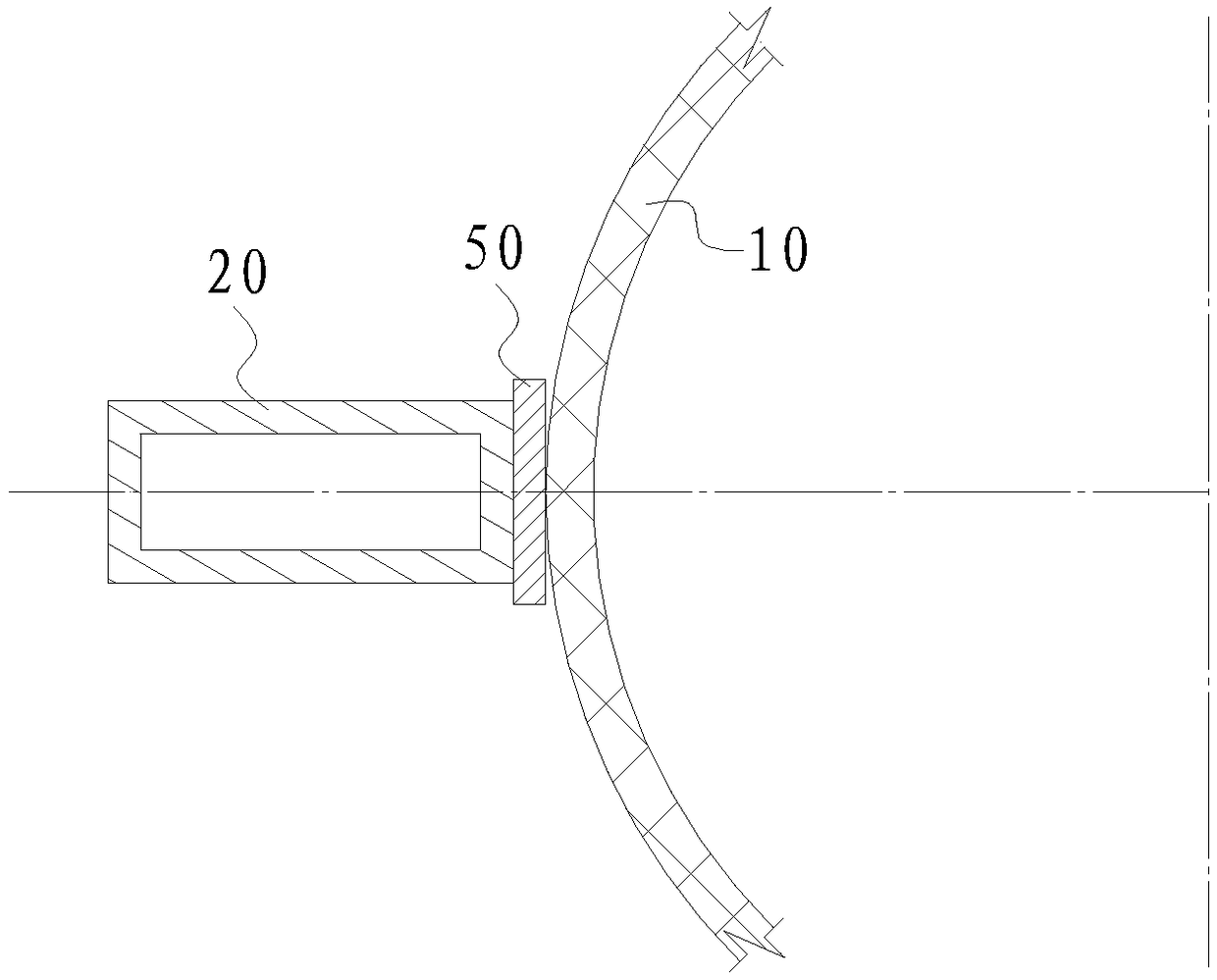

[0024] Such as figure 1 As shown, a reaction tower includes a tower body 10, at least one bearing column 20 and at least one annular structural beam 30, and the bearing column 20 is arranged on the tower body 10 along the axial direction of the tower body 10 On the outer wall of the tower body 10, the annular structural beam 30 is arranged on the outer wall of the tower body 10 along the circumference of the tower body 10, and the bearing column 20, the annular structural beam 30 and the tower body 10 are connected as an integral structure . By setting at least one bearing column 20 and at least one annular structural beam 30 on the wall plate of the tower body 10, the bearing column 20 can bear most of the vertical load, avoiding the local instability of the tower body 10, and the annular structural beam 30 can play a role The lateral connection function strengthens the overall rigidity of the towe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com