garlic seeder

A seeder and garlic technology, applied in potato planters, planting methods, applications, etc., can solve the problems of low automation, low work efficiency, and high labor costs, and achieve the effects of high automation, high work efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

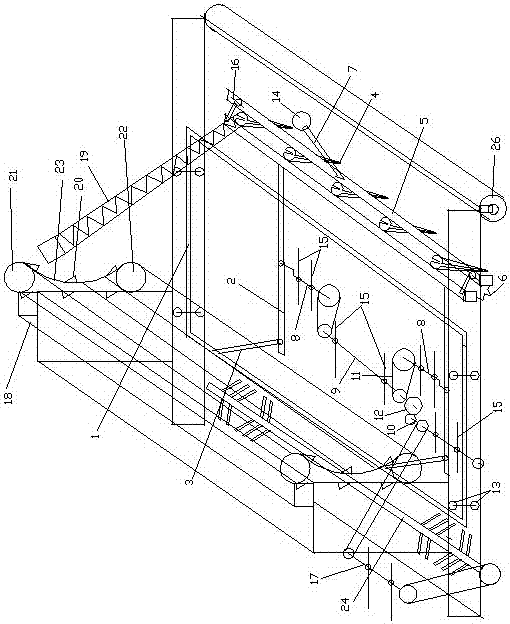

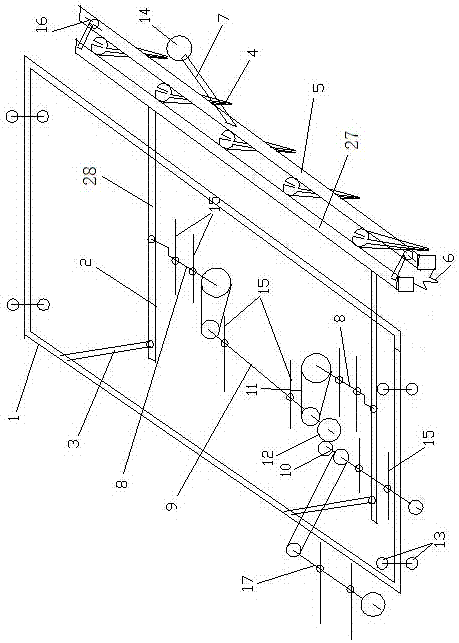

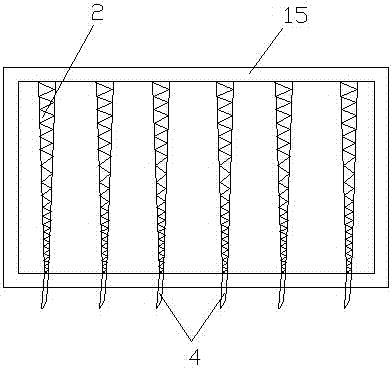

[0020] Accompanying drawing is a kind of specific embodiment of the present invention.

[0021] The garlic planter of the present invention comprises a frame 15 capable of connecting a tractor and a transmission, the transmission is arranged on the frame, the frame is also provided with a feed bin 18, and the frame is also equipped with feeding chains respectively connected to the transmission plate, mobile chassis and leveling screw, the frame is also equipped with falling seed spring 19, the feed chain plate is docked with the feed bin, a large amount of garlic buckets 20 are arranged on the feed chain plate, each garlic bucket accommodates a garlic clove, and several longitudinal The column-mounted garlic hopper corresponds to several falling seed springs one by one. The lower end of each falling seed spring is connected to a columbine leg 4 on the movable chassis. Control the insertion and extraction of columbine legs into and out of the ground and control the row spacing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com