Belt type printing device

A technology of printing device and printing head, which is applied in inking device, printing and other directions to achieve the effect of solving the waste of printing medium and solving the problem of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific embodiments. It should be understood that the following examples are only used to illustrate the present invention but not to limit the scope of the present invention.

[0016] Specific examples.

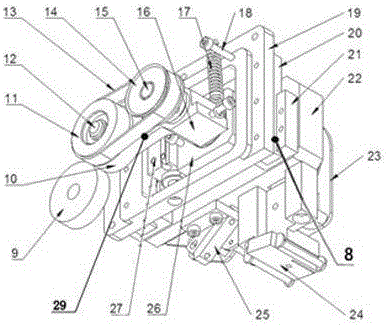

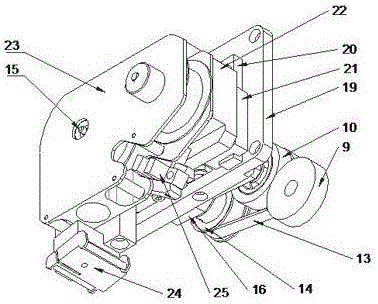

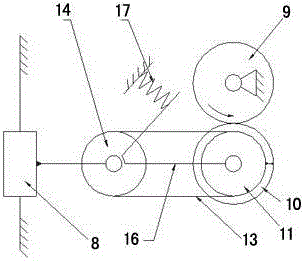

[0017] see Figure 1 to Figure 3 , a tape printing device, including a mobile sub-slider 8, a winding unit 29, a ribbon cassette 23 and a print head 24; it is characterized in that: the mobile sub-slider 8 is composed of a bracket 19, a guide rail 20, a slider 21 and the printing support 22, wherein the bracket 19 is fixedly linked to the guide rail 20, the grooves of the guide rail 20 and the slider 21 are engaged with each other, and the other side of the slider 21 is fixedly connected to the printing support 22; the other side of the printing support 22 is fixed Connect the ribbon box 23; the print head 24 is fixedly linked under the printing support 22; the rewinding unit 29 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com