Gas pipeline drilling and blocking system without transportation interruption

A technology for gas pipelines and pipelines, which is applied in the direction of pipes, pipe components, branch pipelines, etc., can solve the problems of short service life of gear cutters, high cutting noise, cumbersome operation, etc., reduce labor intensity, improve work efficiency and safety , The effect of improving the working speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

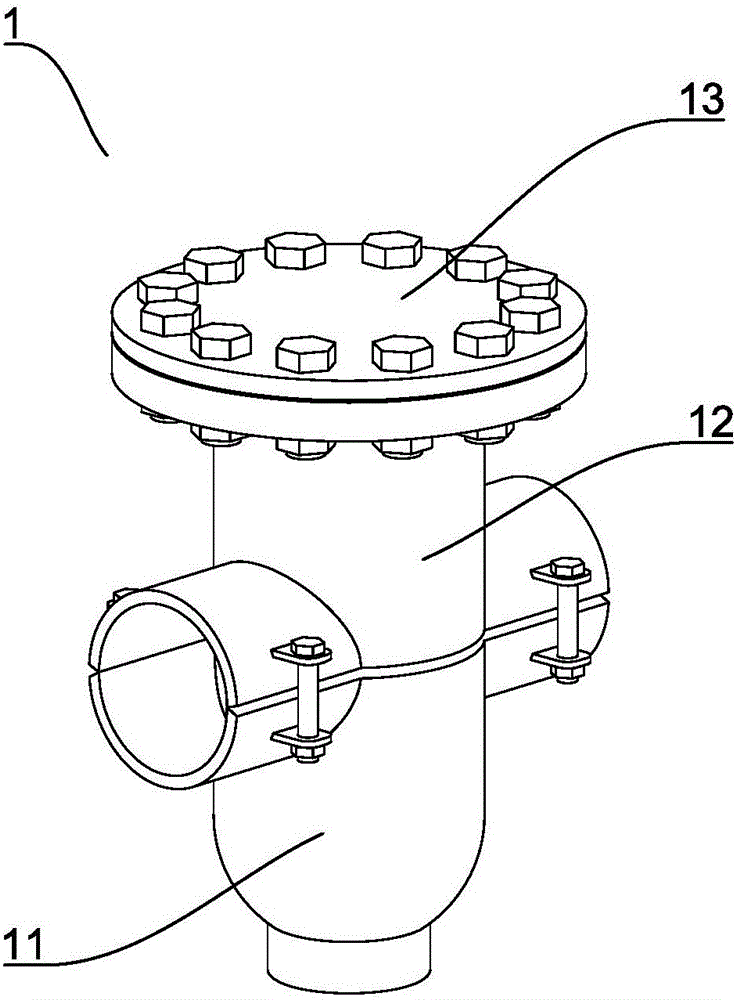

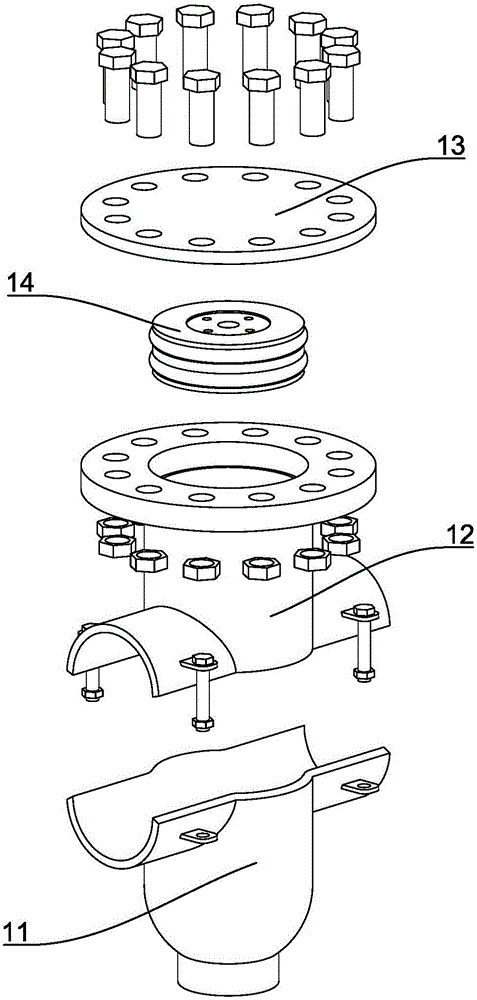

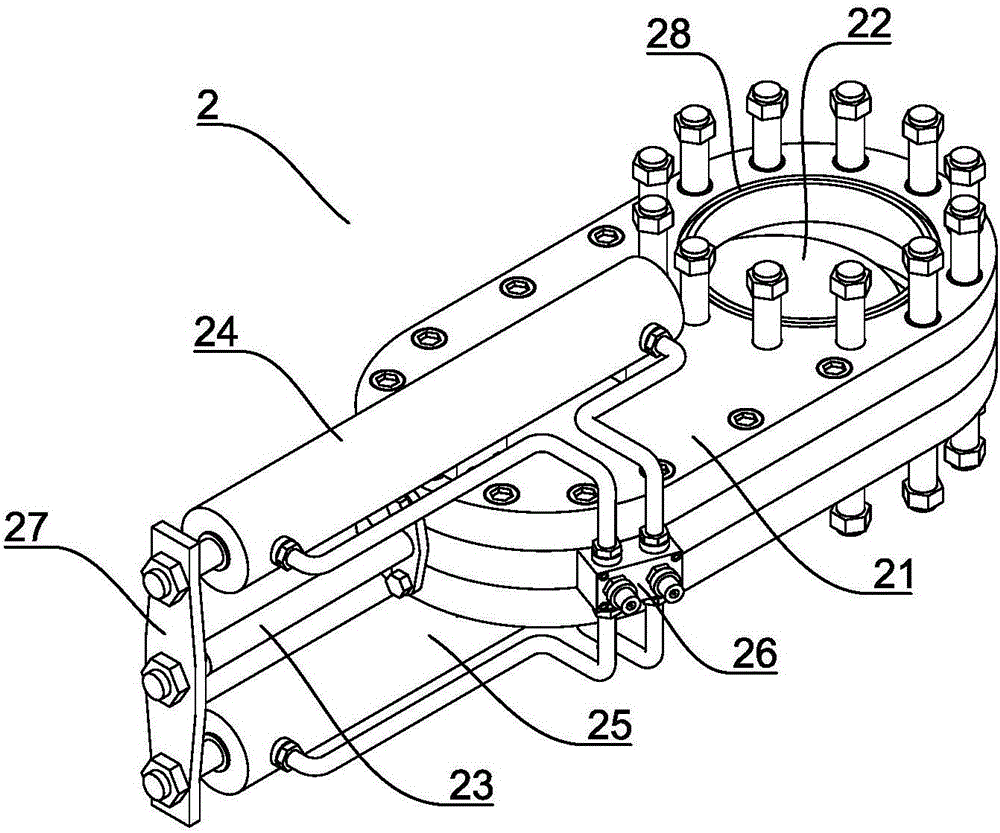

[0037] Such as Figure 1 to Figure 20 Shown in the present invention is a specific embodiment of a non-stop gas pipeline opening and sealing system, which generally includes a four-way pipe fitting 1, a splint valve 2, a hole opening machine 3, a sealing machine 4, a close-toothed knife 5 and a sealing Expansion cylinder 6. The four-way pipe fitting 1 is used for welding at both ends of the pipeline to be repaired during operation. The four-way pipe fitting 1 is provided with a first flange to realize the connection of the splint valve 2 during the operation; the splint valve 2 is installed on the four-way pipe during operation. On the first flange of the pipe fitting 1 and alternately open and close the sealing port during the operation, the opening machine 3 is installed on the splint valve 2 for operation and completes the pipeline cutting process through the fine-toothed knife 5 therein; the sealing machine 4 When used for operation, it is installed on the splint valve 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com