High-frequency resonant soft switch circuit fault prediction method and high-frequency resonant soft switch circuit fault prediction device based on compressed sensing

A technology of high-frequency resonance and compressed sensing, which is applied in the direction of measuring devices, electronic circuit testing, output power conversion devices, etc., can solve the problems of high difficulty coefficient of data processing and low accuracy of fault prediction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with examples, but the present invention is not limited to these examples.

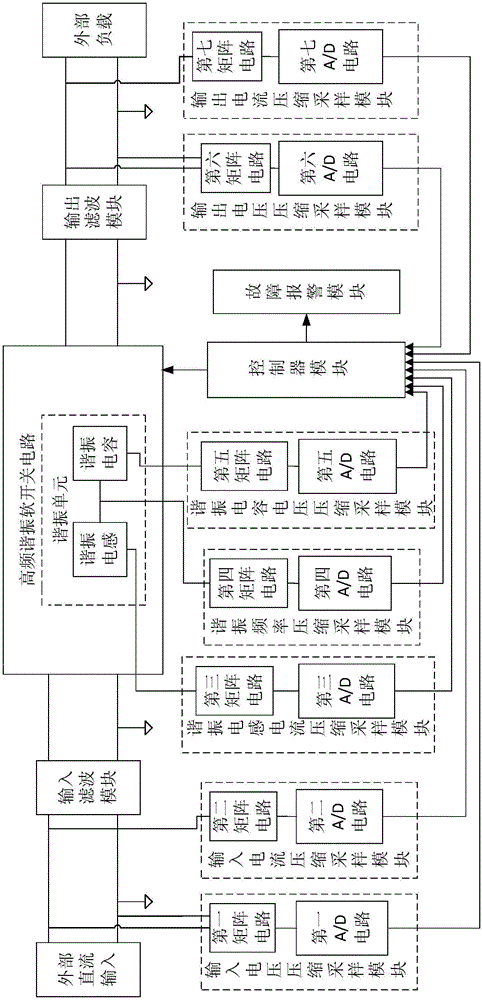

[0060] In the high-frequency resonant soft-switching power supply, the high-frequency resonant soft-switching circuit is the core part, which is composed of a DC-DC converter and a power converter. The DC-DC converter converts the voltage value of the DC input signal, and performs isolation, noise reduction, voltage stabilization and overvoltage protection. The output signal is smooth DC, without AC harmonic components, and the output impedance is zero, with fast The ability of dynamic response and strong suppression ability. The power converter adopts the resonant switching conversion technology, and uses the resonant switch for conversion. It is a partial resonant conversion process. The switching loss is small, and the switching loss can be zero when the control is appropriate; A half-period resonance is performed during t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com