Cable hole high temperature resistant waterproof plugging device

A occluder and high temperature resistant technology, which is applied in the direction of electrical components, pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of complicated installation and disassembly of occluders, poor fire performance, and low temperature resistance, etc., to achieve installation and Easy and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

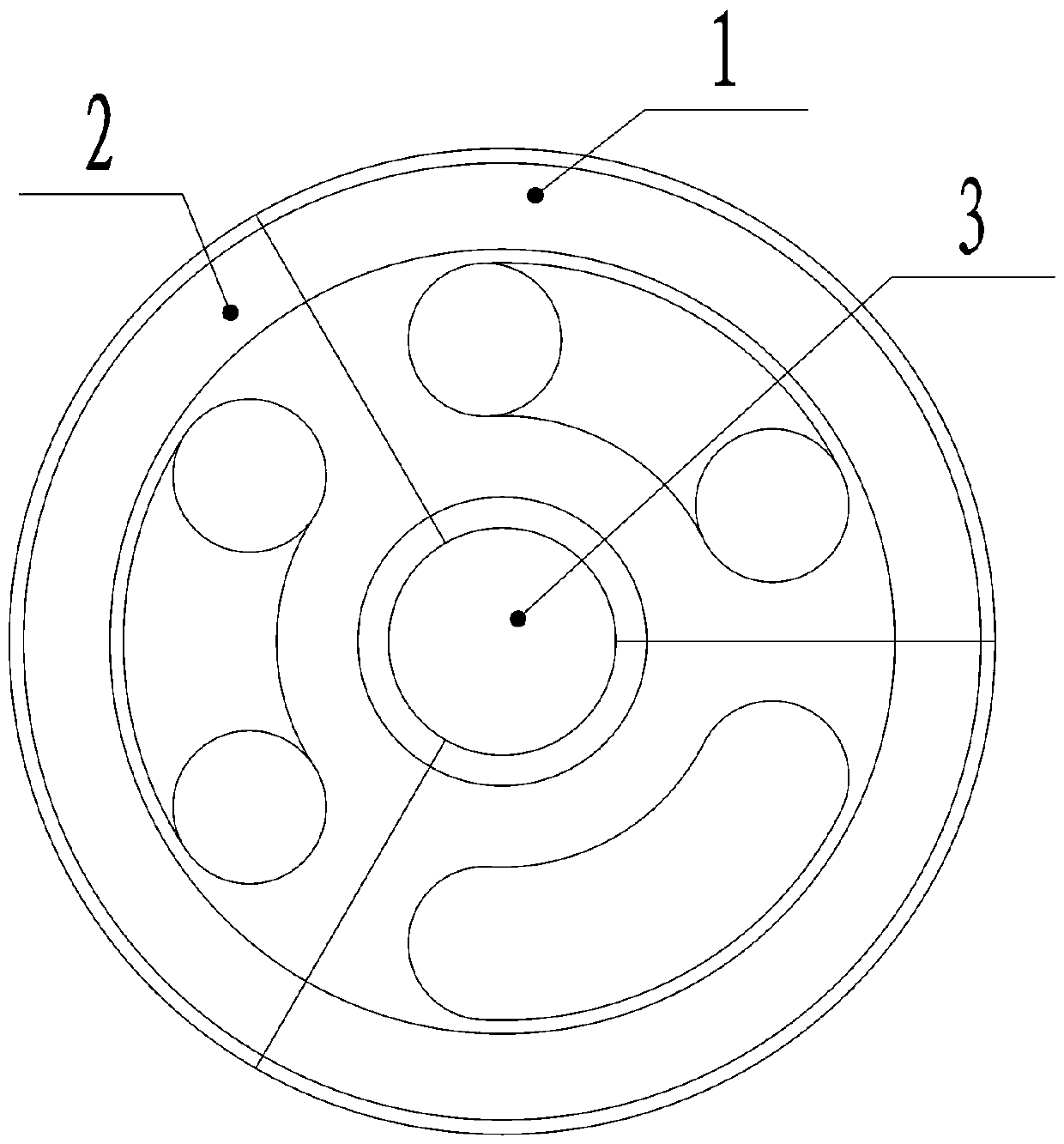

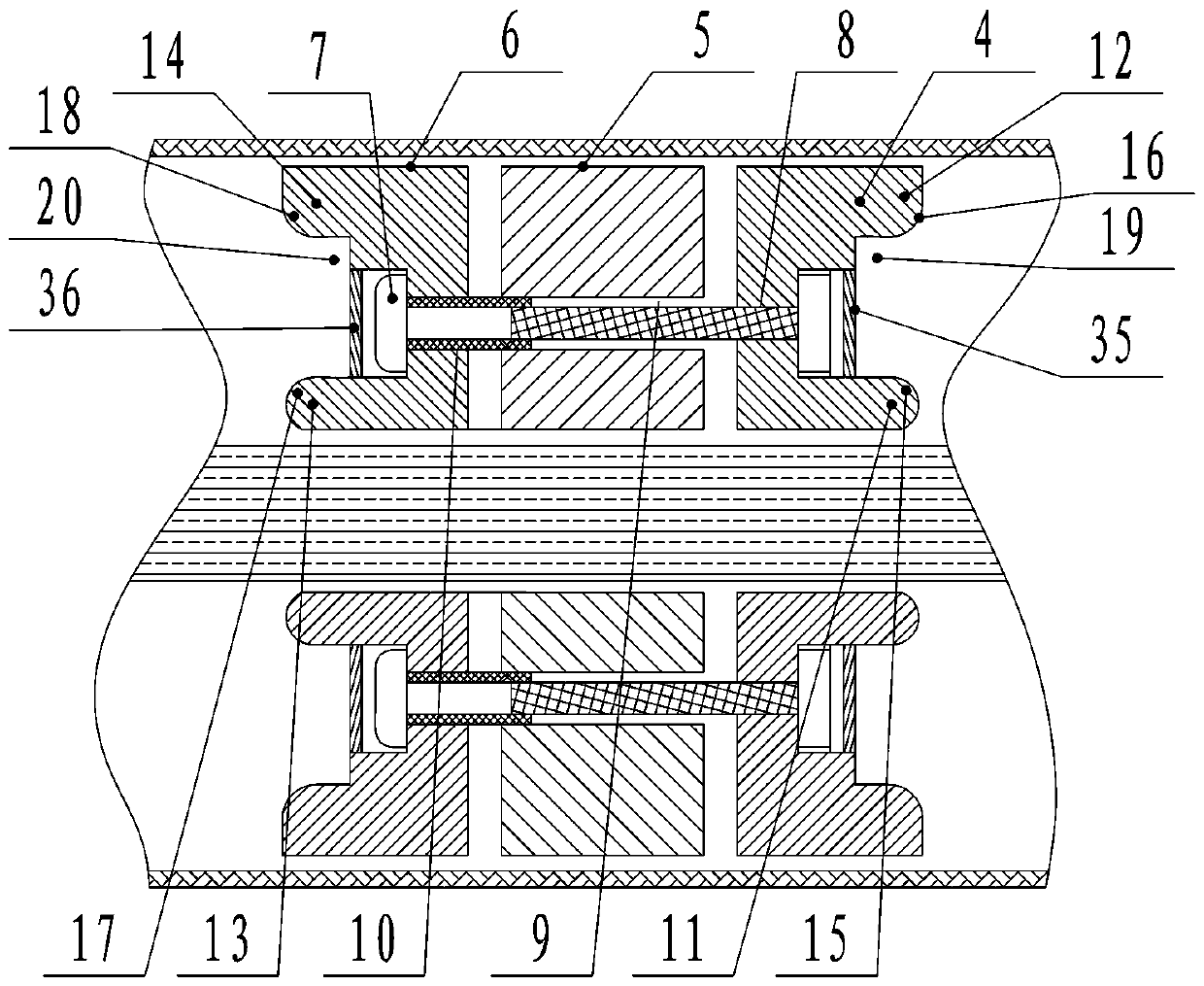

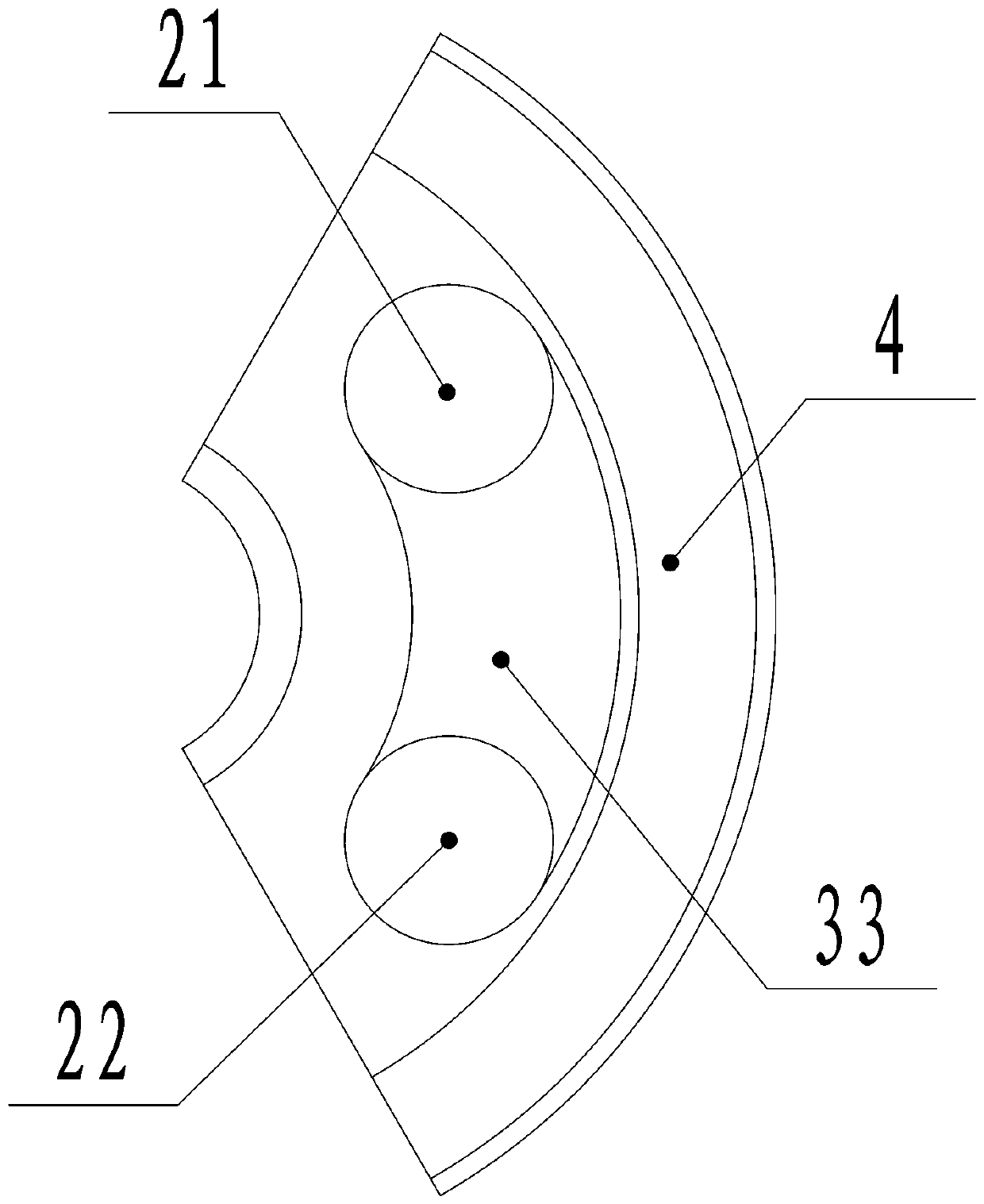

[0021] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 and Figure 7 As shown, the embodiment of the cable hole high temperature resistant and waterproof occluder, the occluder 1 is composed of multiple sets of occluding parts 2, the occluding device 1 has a cable installation hole 3, and the occluding part 2 includes a front ceramic block 4. The deformable middle gasket 5, the rear ceramic block 6 and the connecting fixture 7, the front ceramic block 4 has a front ceramic block installation hole 8, the middle gasket 5 has a middle gasket installation hole 9, the The rear ceramic block 6 has a rear ceramic block installation hole 10, the front ceramic block installation hole 8, the middle sealing pad installation hole 9 and the rear ceramic block installation hole 10 communicate, and the connecting fixture 7 passes through the front ceramic block installation hole 8 , middle sealing pad mounting hole 9 and rear ceramic block mounting hole 10, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com