TPMS leaving-assembly calibration method and TPMS leaving-assembly calibration equipment based on bidirectional tire pressure

A calibration method and equipment technology, applied in tire measurement, tire parts, inflatable body pressure measurement, etc., can solve the problems of troublesome operation, low production efficiency, etc., and achieve the effects of short time, improved production efficiency, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

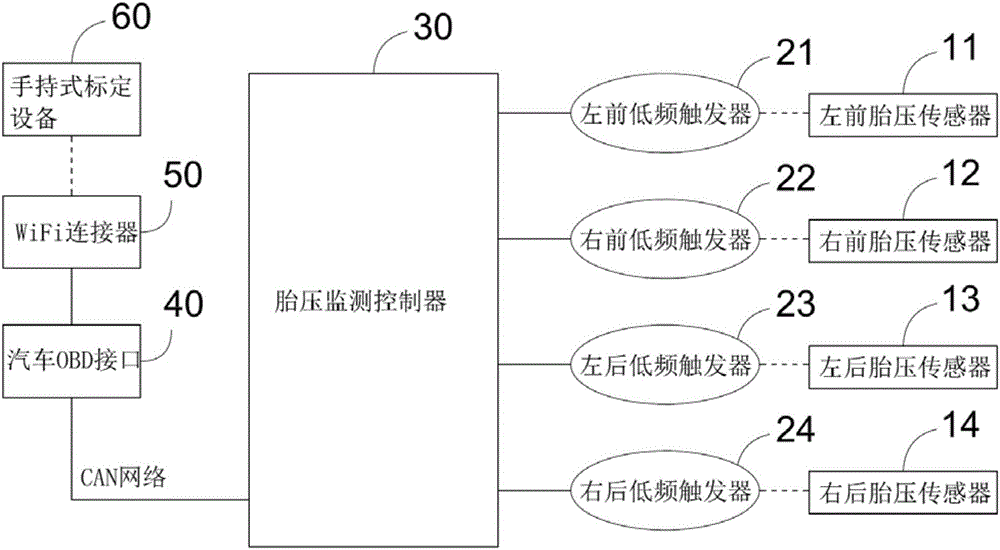

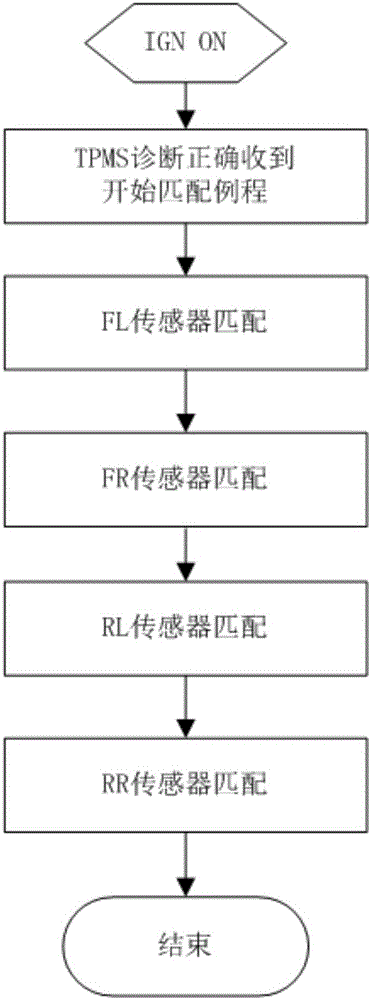

[0019] refer to figure 2 and image 3 , a kind of TPMS off-line calibration method based on two-way tire pressure of the present invention, comprises the following steps:

[0020] Connect the WiFi connector 50 to the car OBD interface 40, the handheld calibration device 60 is connected to the WiFi connector 50 through WiFi communication, the handheld calibration device 60 after the communication connection is connected to the car CAN network through the car OBD interface 40, and finally connected The tire pressure monitoring controller 30 forms a communication connection;

[0021] After the device is connected, operate the tire pressure calibration button on the hand-held calibration device 60, and send the “Left Front Tire Pressure Calibration Command” through WiFi communication. After receiving the WiFi signal, the WiFi connector 50 transmits it to the tire pressure monitoring via the CAN network of the car. controller 30;

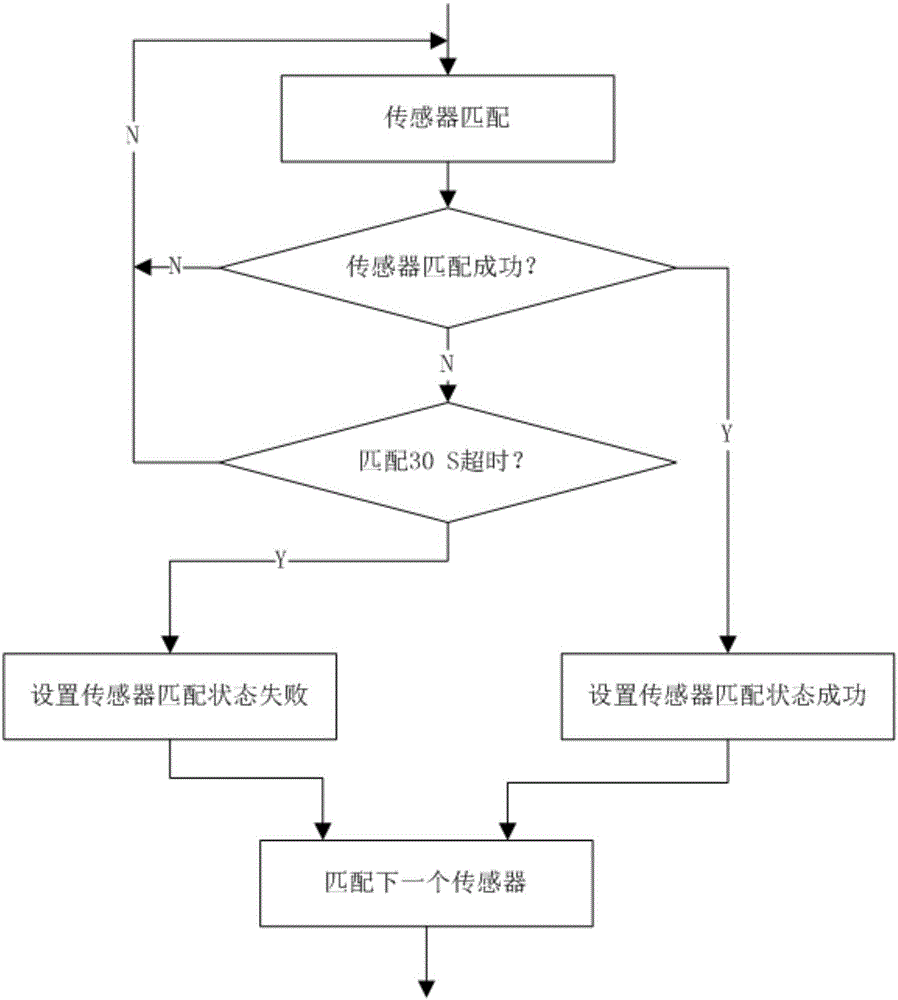

[0022] After receiving the calibration instruc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com