An All-round Buffering Shock Absorbing Seat for Textile Machines

A machine shock-absorbing seat, all-round technology, applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve problems such as worker health impact, large impact force, textile machine impact, etc., and achieve equipment height adjustment Convenience, improve shock absorption, reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

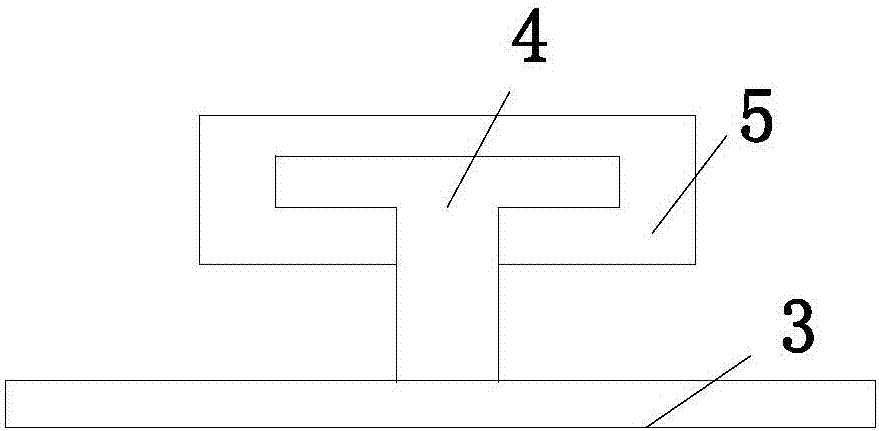

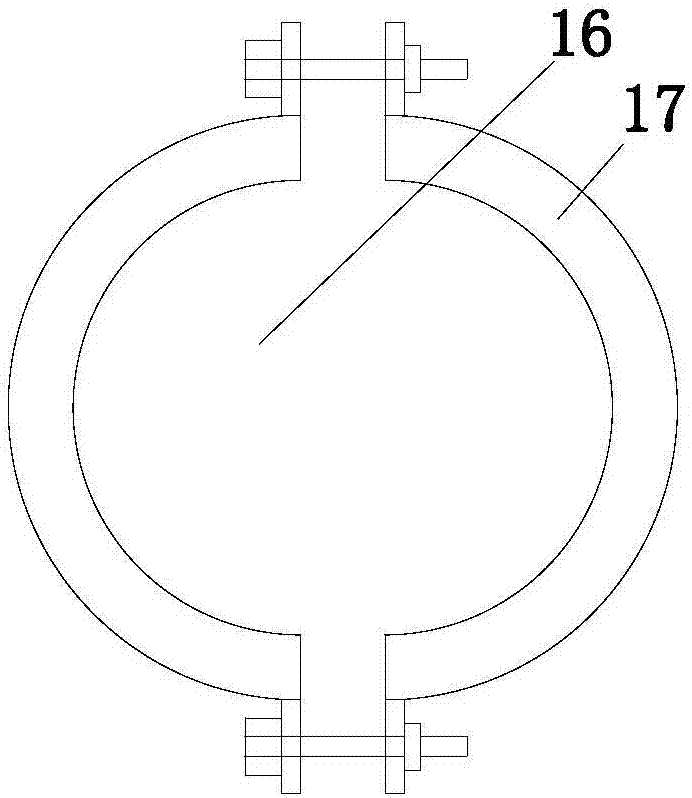

[0016] Embodiment: a kind of all-round cushioning textile machine shock-absorbing seat, constitutes as figure 1 , 2 As shown in and 3, a fixed frame 1 is included, a small hydraulic jack 2 is arranged in the fixed frame 1, and a first support plate 3 is provided at the extension end of the hydraulic jack 2, and a plurality of fixed guide rails 4 are arranged on the first support plate 3, The fixed guide rail 4 is connected with a sliding guide rail 5, the top of the sliding guide rail 5 is provided with a first hollow cylinder 6, the first hollow cylinder 6 is provided with a second hollow cylinder 7, and the second hollow cylinder 7 is lower than the first hollow cylinder 6. A first spring 8 is arranged between a hollow cylinder 6 and the second hollow cylinder 7, a second spring 9 is arranged in the first hollow cylinder 6, a third hollow cylinder 10 is arranged above the second spring 9, and a third hollow cylinder 10 Embedded between the first hollow cylinder 6 and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com