Coupled linear direct drive float type wave energy generation device

A power generation device, float type technology, applied in ocean energy power generation, engine components, machines/engines, etc., can solve the problems of high natural frequency, severe float vibration, and excessive voltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

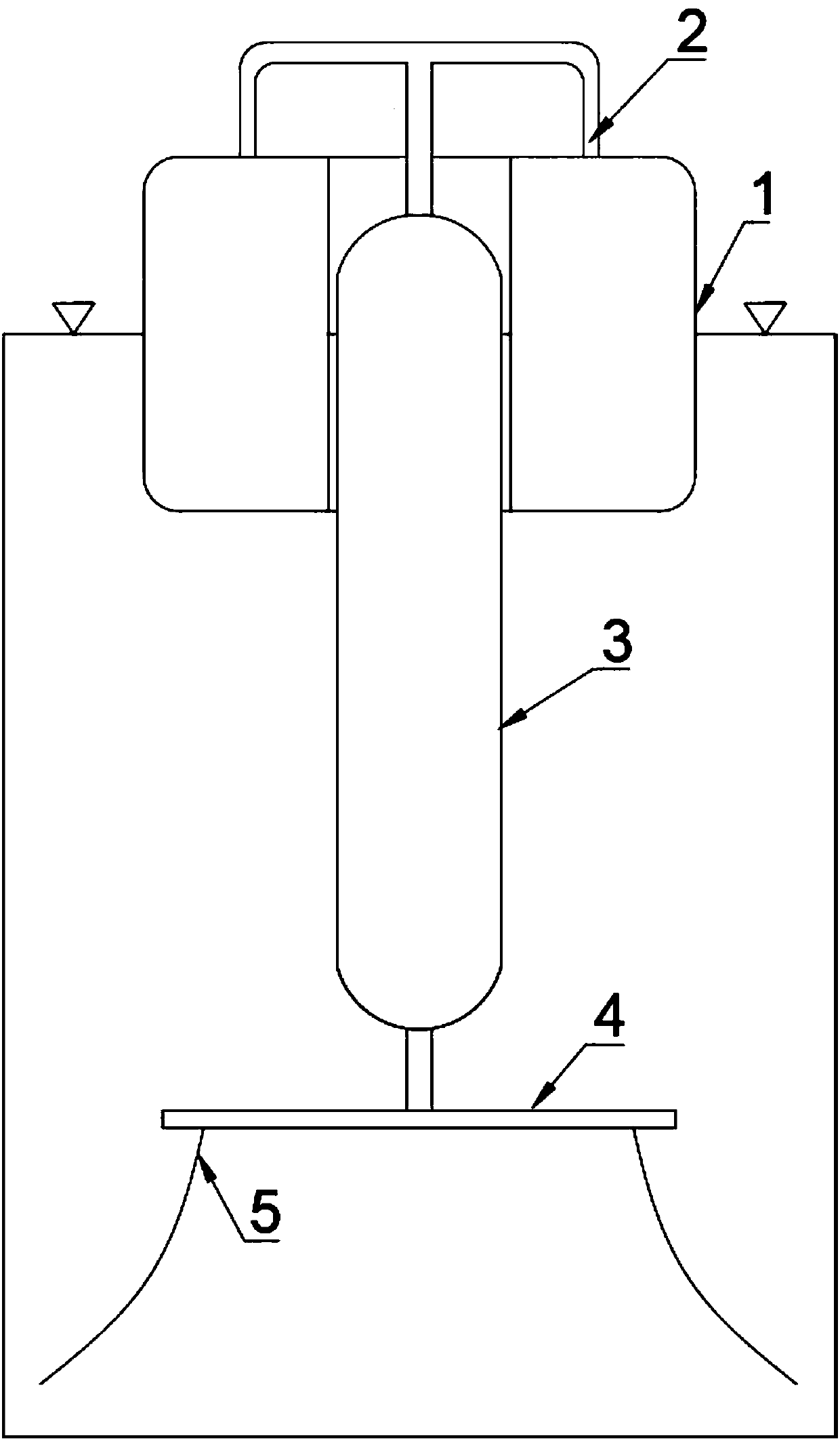

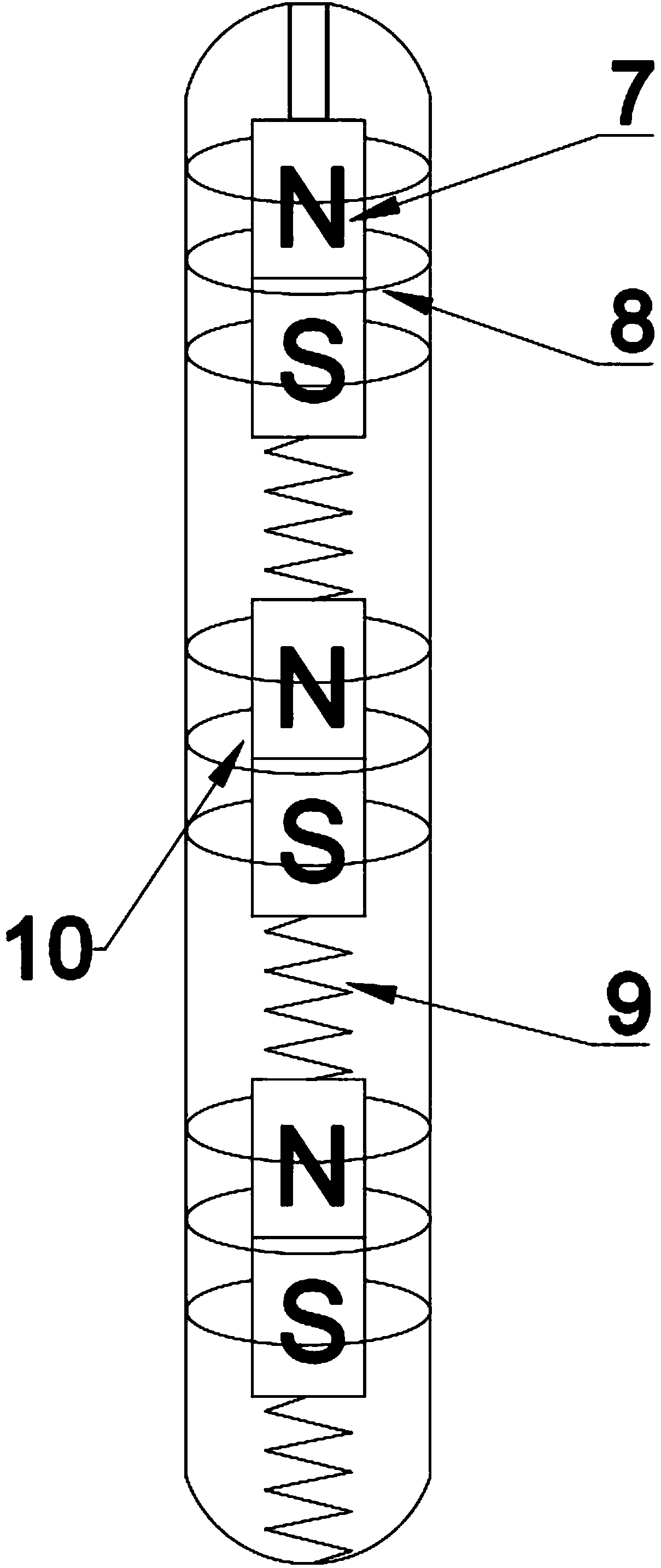

[0024] The first embodiment of the present invention provides a coupled linear direct-drive buoy type wave energy generating device, which includes a base, which is a heave plate 4 fixed in the sea by several anchor lines. The columnar generating device 3 is fixed on the upper surface of the heave plate 4, and a through hole for the connecting shaft 2 to pass is provided on the top of the columnar generating device 3, a seal is also provided on the through hole, and the seal is sleeved On the connecting shaft 2, the connecting shaft 2 can slide up and down relative to the sealing member. A plurality of magnets 7 are arranged inside the columnar generator 3, and the magnets 7 are arranged vertically in sequence to form a straight line, and the N poles of the magnets 7 point to the top or bottom of the columnar generator. Two adjacent magnets 7 are connected to each other by an elastic member, which can be a spring 9, or an elastic connecting member such as a rubber band. The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com